Basic HTML Version

30

Geotechnical News • December 2012

www.geotechnicalnews.com

GEOTECHNICAL INSTRUMENTATION NEWS

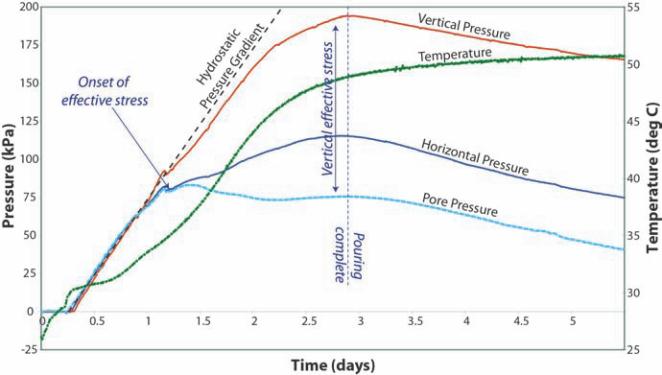

pressure, indicating the onset of effec-

tive stress and therefore enhanced

backfill stiffness and strength. In

addition, exothermic binder reactions

are reflected in rising temperatures. It

is therefore desirable to see effective

stress and temperature rise occurring

simultaneously. An example of such a

data trend is shown in Figure 2. Note

that Figure 2 also includes vertical

total stress as a matter of interest,

although this would not generally be

required for barricade monitoring.

Interpretation of results

The monitored parameters are inter-

preted both quantitatively and quali-

tatively. The total pressure acting on

the barricade must remain below its

rated safe limit, otherwise backfill-

ing must be stopped so that pres-

sures can subside before backfilling

resumes. Ideally, the onset of effective

stress and temperature rise should be

observed before the backfill reaches

the full barricade height, as this condi-

tion indicates that the barricade is now

beginning to interact with solid to

semi-solid material.

Suggested instrumentation

strategy

Transducer types

Although measuring pore water pres-

sure is relatively straightforward, there

are many well documented issues

associated with measuring total pres-

sures in a granular material. One sig-

nificant issue is matching the stiffness

of the TEPC with that of the surround-

ing medium. This is all the more dif-

ficult when the stiffness of the material

is changing, as is the case for backfill.

The approach taken in this work was

to use TEPCs with the highest practi-

cal aspect ratio (diameter:thickness)

and stiffness possible. The merits of

this approach can be debated but such

details, while important, are beyond

the scope of the current article.

TEPCs and piezometers of the vibrat-

ing wire type have been used, supplied

by two leading manufacturers. The

TEPCs used have been about 250 mm

(10 in.) diameter with sensing sur-

face on one side (also called “contact

cells”) and about a 20:1 aspect ratio.

All of the transducers have thermistors

and provide a temperature data chan-

nel. During the initial filling stage,

while the backfill is still a fluid, both

manufacturers’ TEPCs have given

pressure readings consistent with the

piezometer up to the onset of effec-

tive stress, which is one of the critical

indicators of good backfilling prac-

tice. Subsequently, there appear to be

TEPC response differences that cannot

be currently adequately explained, and

therefore further research is needed

into the performance of these cells

in curing backfill where the stiffness

changes with time.

Transducer calibration

Manufacturers provide calibration

sheets for their vibrating wire piezom-

eters and TEPCs. The thermal and

fluid pressure calibrations have been

found consistently reliable for many

hundreds of transducers used in the

field to date. However, as explained

above, TEPC calibration is much

more problematic when the stiffness

of the material changes with time,

and it is therefore not advised that

mine-specific TEPC calibration be

attempted at present. Indeed, there are

other logistical considerations that can

be far more influential on the output

of TEPCs, and so attention to detail

in the construction and deployment

of the system is a more important

consideration.

Building and deploying a system

At least one TEPC and one piezometer

are recommended for routine bar-

ricade monitoring. These transduc-

ers should be installed at the same

elevation so that piezometer readings

can be directly subtracted from TEPC

readings to obtain effective stress.

Mounting the transducers directly to

the back of the structural barricade

is not recommended, as variations in

barricade stiffness and drainage condi-

tions make measurements there too

localized. Instead, it is recommended

that the transducers be placed within

the backfill about 2 m behind the bar-

ricade and at about one-third barricade

height. Ideally the mine should work

with the instrumentation supplier to

have an instrumentation module pre-

built so that the two transducers are

delivered on a frame that can be easily

Figure 2. Ideal monitoring data showing temperature increase and develop-

ment of effective stress (i.e., total pressure exceeding pore water pressure).