Basic HTML Version

30

Geotechnical News • March 2013

www.geotechnicalnews.com

THE GROUT LINE

largest in the United States. Immedi-

ately downstream of the dam is a trout

hatchery operated by the US Fish and

Wildlife Service.

Two grout lines were required by the

contract. The first grout line was in the

gallery tunnel near the base of the con-

crete gravity structure. A second grout

line was along the downstream toe

near the contact between the concrete

and earth fill adjacent to the switch-

yard associated with the hydroelectric

powerhouse. Both grout lines paral-

leled grout lines placed in the 1940s

(gallery) and 1968-1975 (downstream

toe). The designers decided that it

would be beneficial to be able to dif-

ferentiate between the modern grouts

and historical grouts by color, and thus

required dyed grout. In addition, it

was thought that dyed grout would be

easier to notice if grout found its way

into the trout hatchery intake, which

was located as close as 50-feet to the

downstream toe grout line. Figure 1

shows the location of the grout lines,

along with the trout hatchery.

Methods

A wet dye injection system was

utilized for the injection of dye at

Wolf Creek. Dye was provided by the

supplier wet and injected wet. Col-

loidal grout mixers were utilized by

the contractor to mix the grout, and

the dye was mixed with the grout in

the colloidal mixer. The ASTM C

979-compliant dye chosen by Judy

Company was sourced from Solomon

Colors, and yellow was the color cho-

sen. The dye was mixed at 2.5-percent

by weight of cementitious material

(Portland cement plus fly ash).

Wasted grout is a fact of life on

production grouting jobs, and dyed

grout could complicate disposal. Grout

that is not injected into grout holes

is typically wasted; this includes the

quantity used to fill the grout lines.

Once hardened, the dye is trapped

in the grout. However, in the liquid

state or semi-solid state, when mixed

with water, there is the probability

that the water-soluble dye could enter

the waste water stream. Dyed water

is pretty obvious when entering a

watercourse.

A temporary waste water treatment

plant was established at the beginning

of the job to treat drilling fluids, rain-

water, water from gallery drains, waste

grout and other associated contract

waste waters. The Corps had concern

that some dyes may be very difficult to

remove from the waste-water stream,

and therefore did not specify the color

to be used. Discharge of dyed water

into the Cumberland River would be

negative from several standpoints. The

waste water treatment plant was able

to successfully remove all traces of

dye from the discharge water.

Effects of the dye on grout

There were rigorous grout testing

requirements on this contract. A suite

of six grout mixes was developed by

the contract to meet contract require-

ments, with water-to-cement ratios

ranging from 1.9 to 0.7. Grout mixes

were tested every four hours for

viscosity using a Marsh funnel and

density using a mud balance. Every

day, grout cubes were cast and later

tested for compressive strength at 7,

14, and 28 days. Bleed and pressure-

filtration tests were conducted weekly.

Initial set time and final set time tests

were conducted monthly. Testing

showed the dyed grout to consistently

be within specified limits.

One day, a batch of un-dyed grout

was mixed immediately before a dyed

grout batch; testing showed little dif-

ference in physical properties between

dyed and un-dyed grout. Compressive

strength testing was performed on

un-dyed and dyed grouts. The strength

differences were negligible. The same

batches were tested for Marsh Fun-

nel Viscosity, Mud Balance Density,

Bleed, Pressure Filtration, and Set

Time. None of these tests showed any

differences between the dyed and un-

dyed grout.

Results

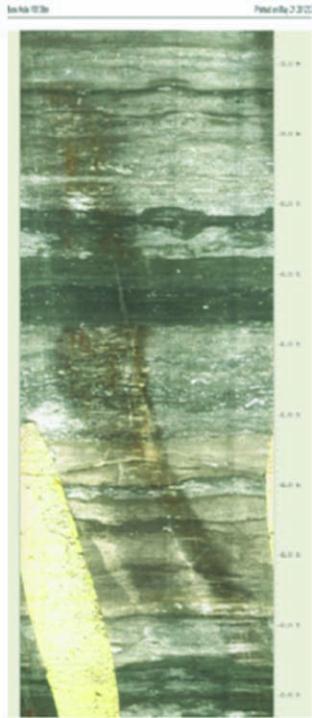

The dyed grout worked as desired.

Figure 2 shows a photograph of hard-

Figure 2. Dyed and un-dyed Grout

Samples. Concentrations of dye (by

weight of cement) are 0-percent,

2.5-percent, 5-percent, and 7.5-per-

cent, as marked on the samples.

Figure 3. Dyed grout in an inter-

sected hole in a downhole camera

image. The image shows the entire

circumference of the hole. Noted

depth intervals are 6-inches on the

right side, interval for image is 58.76

ft to 63.65 ft.