Basic HTML Version

36

Geotechnical News • June 2014

www.geotechnicalnews.com

GEOSYNTHETICS

Terzaghi’s path-of-discovery toward

the design of granular filters (Fannin,

2008). I grew to appreciate the legacy

of his systematic experimentation as a

university academic, his challenging

assignments as a specialist consultant,

his life-long respect for the influence

of minor geologic features, his rigor-

ous approach to the interpretation of

evidence, and his unstinting commit-

ment to performance monitoring. And

with this appreciation, I too sought

out every opportunity to ensure that I

had a proper understanding of events

related to the nature and origin of

geotechnical filter design, for which I

acknowledge, with gratitude, con-

versations with several individuals

including Terzaghi’s co-author on the

textbook “Soil Mechanics in Engineer-

ing Practice”, Ralph Peck, at the 57

th

Canadian Geotechnical Conference

(Fig. 3).

I also have no doubt that Terzaghi

brought the same unstinting commit-

ment to excellence when he oversaw

the design and installation of a PVC

membrane liner during construc-

tion of the 55 m high Mission Dam,

British Columbia, Canada that was

subsequently renamed the Terzaghi

Dam, in 1965. As might be expected,

the problem was anything but simple.

Following early exploratory work in

1955, placement of zoned embank-

ment materials commenced in 1957

and continued through to 1960

(Terzaghi and Lacroix, 1964). The

dam is founded on a discontinuous

clay stratum that is underlain by sand

and gravel, and overlain by alluvial

and river channel deposits. The clay

stratum itself represents the down-

stream portion of glacial lake deposits

arising from the last stage of reces-

sion of the Pleistocene ice sheet: the

boundary between it and the overlying

coarse-grained sediments was found

to be clear but very uneven, likely as a

result of geological processes follow-

ing retreat of the valley ice. Settlement

of the embankment occurred during

construction, including differential

settlements of up to 3 m. The zoned

embankment dam has a sloped till-

core that is covered by an upstream

blanket of plastic clay, about 2.5 m

thick. The performance of the dam is

contingent on the clay blanket remain-

ing intact, without any cracks or

fissures arising from the influence of

differential settlement. Concern for the

adverse impact of any cracking led to

the decision to cover select portions of

the clay blanket with a plastic mem-

brane. The choice of plastic material

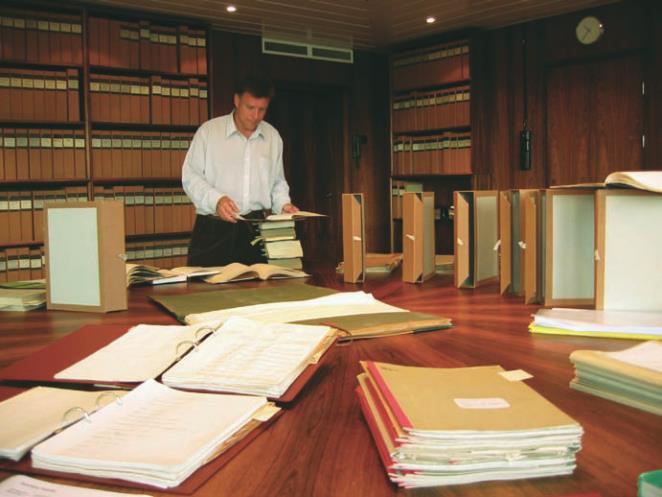

Figure 2. Reading through professional correspondence in the Terzaghi

Library at the Norwegian Geotechnical Institute.

Figure 3. Consultation with Ralph Peck on the origins of the filter design

criteria appearing the “Soil mechanics in engineering practice” co-authored

with Karl Terzaghi.