Basic HTML Version

www.geotechnicalnews.com

Geotechnical News • September 2014

23

GEOTECHNICAL INSTRUMENTATION NEWS

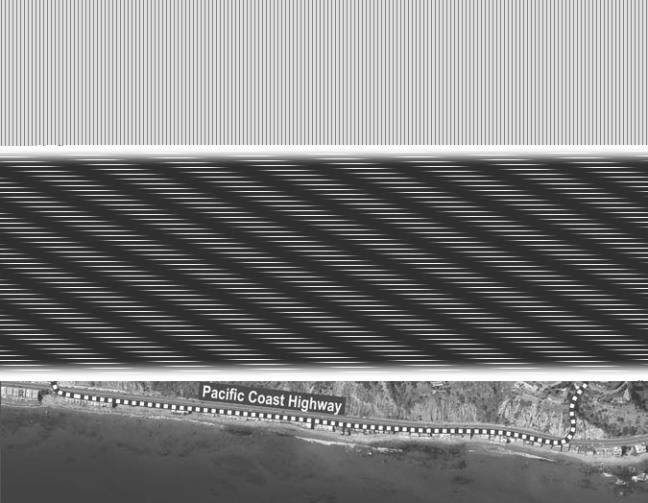

Figure 1. Big Rock Mesa Landslide – Malibu, California.

the type of monitoring that was

performed, how the data that were

collected differed from the expected

results, and how those discrepancies

were ultimately resolved. The type of

instrumentation associated with these

case histories includes inclinometers

and piezometers.

Upslope inclinometer offsets at

Big Rock Mesa Landslide

The first case history involves a large

(200+ acre) landslide in Malibu,

California referred to as the Big Rock

Mesa Landslide (see Figure 1). The

landslide activated in 1983 after an

extended period of heavy rainfall. The

basal rupture surface of the landslide

was up to approximately 250 feet deep

with a series of apparent secondary

failures along the steep coastal bluff.

The general orientation of the basal

rupture surface was defined using a

series of inclinometers. A simplified

cross section through the landslide is

provided as Figure 2. One of the incli-

nometers was installed along the top

of the coastal bluff. That inclinometer

indicated progressive shearing in an

upslope direction with no offsets in the

apparent direction of landslide move-

ment. This data initially confounded

a number of investigators and it was

speculated that either the orientation

of the inclinometer axes had been

recorded incorrectly or the inclinome-

ter casing was twisted or rotated above

the depth at which the movement

was occurring. Both of these poten-

tial explanations were evaluated and

disproved. A finite element model of

the landslide was developed to evalu-

ate stresses and deformation patterns

within the mass (see Figure 3). This

model indicated the abrupt upward

curvature of the basal rupture surface

which occurred along a fault that

extended along the shoreline would

indeed induce a stress pattern consis-

tent with the reverse shearing observed

in the inclinometer. To further evaluate

the results predicted by the computer

model, a 1:50 scale physical model of

the landslide was created (Figure 4).

The physical model consisted of a ¼“

thick piece of aluminum plate that was

bent to match the shape of the basal

rupture surface. The upper surface of

the aluminum plate was then covered

with a thin layer of wax. Fine, moist

sand was then placed on the alumi-

num plate and molded to conform

to the topography of the landslide. A

small amount of powdered bentonite

was mixed with the sand to provide

a scaled level of apparent cohesion

consistent with the formational materi-

als that comprised the landslide. The

simulated landslide failure surface was

then slowly heated using a series of

thermal strips attached to the bottom