Basic HTML Version

46

Geotechnical News • December 2014

www.geotechnicalnews.com

WASTE GEOTECHNICS

models and to increase confidence in

their results. The laboratory tests are

integrated into the process for water

recovery estimates using the approach

shown in Figure 2.

The laboratory testing procedure

allows for the assessment of sedimen-

tation and evaporation from the tail-

ings and consists of columns that are

built using acrylic cylinders as shown

in Figure 3. The columns are nomi-

nally 15.24 cm in diameter, 40-cm

high and equipped with:

• Measuring tape to track settlement

of tailings in the column;

• Piezometers to track pore water

pressures;

• Tensiometers to track negative pore

water pressures (suction); and

• Ports to collect drainage and tail-

ings samples to determine mois-

ture content.

The tailings are placed in the columns

at the target solids content dictated by

mill processing, and water losses are

tracked for several days by measuring

the weight of the column and water

outflows. Weight measurements with

time determine the water losses from

sedimentation (or potential surface

runoff) and evaporation from the tail-

ings or actual evaporation (AE).

Relative humidity (RH) and room

temperature (under laboratory condi-

tions) are measured throughout the

test and the weight loss of a column

filled with water is used to determine

the rate of potential evaporation (PE)

during the test. These data serve as

the climatic input for validation of the

numerical models.

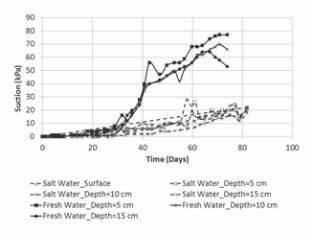

Typical laboratory test results are

shown in Figures 4a, b and c and

include PE, RH, temperature, water

losses in grams or as a percentage of

initial mass of water (%IMW) and

suction at different depths with time.

Calibration of models and

predictions of tailings drying

under field conditions

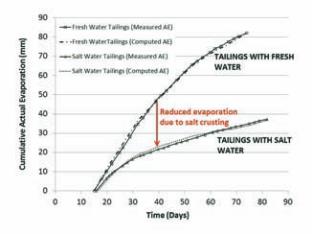

The results obtained from the labo-

ratory tests are used for calibration

of the numerical models required to

predict evaporation and infiltration

from the tailings. Calibration is car-

ried out by comparing the AE from

the tailings to modelled results using

material properties and climatic data

(PE, RH and temperature) measured in

the laboratory. The calibration process

generally considers:

• Determining the initial condition of

the tailings at the time evaporative

drying begins (in terms of their av-

erage density) based on the results

of the sedimentation stage;

• Adjusting unsaturated properties

such as soil water characteristic

curves and more importantly hy-

draulic conductivity functions; and

• Developing appropriate consid-

erations in the model to address

the effect of crusts at the surface

(crusts due to accumulation of salt

at the surface result in a decrease

of evaporation due to the increase

of osmotic suction as shown in

Figure 5a).

Computed results for AE are com-

pared to those measured in the labora-

tory, and calibration is completed once

computed and measured values agree

(as shown in Figure 5a).

The calibrated unsaturated models

are then used to predict the expected

response of tailings layers under aver-

age field climatic conditions, and the

results are combined with the deposi-

tion plan to determine water recovery

from the surface of the impoundment.

The numerical models to predict field

conditions are developed to obtain

Figure 4a. Potential evaporation

(PE), relative humidity (RH) and

temperature versus time.

Figure 4b. Total water losses from

tailings (sedimentation and evapora-

tion).

Figure 4c. Suction within the tailings

versus time.

Figure 5a. Computed and measured

evaporation for tailings prepared

with fresh water and seawater under

the same laboratory conditions.

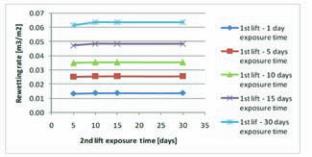

Figure 5b. Expected rewetting losses

(m3/m2) as a function of tailings

drying time (days).