56

Geotechnical News March 2011

WASTE GEOTECHNICS

sand (STP-07-159-SS). This zonation,

which may reflect differences in

redox conditions, provides a means

of monitoring the interaction of PA-

injectate within two chemically distinct

layers of the aquifer. Slug testing found

the hydraulic conductivity to be 6.4 x

10-3 m s-1 in the shallow zone and 2.4

x 10-3 m s-1 in the deeper region, while

groundwater chemistry suggests the

entire aquifer may be mildly anaerobic.

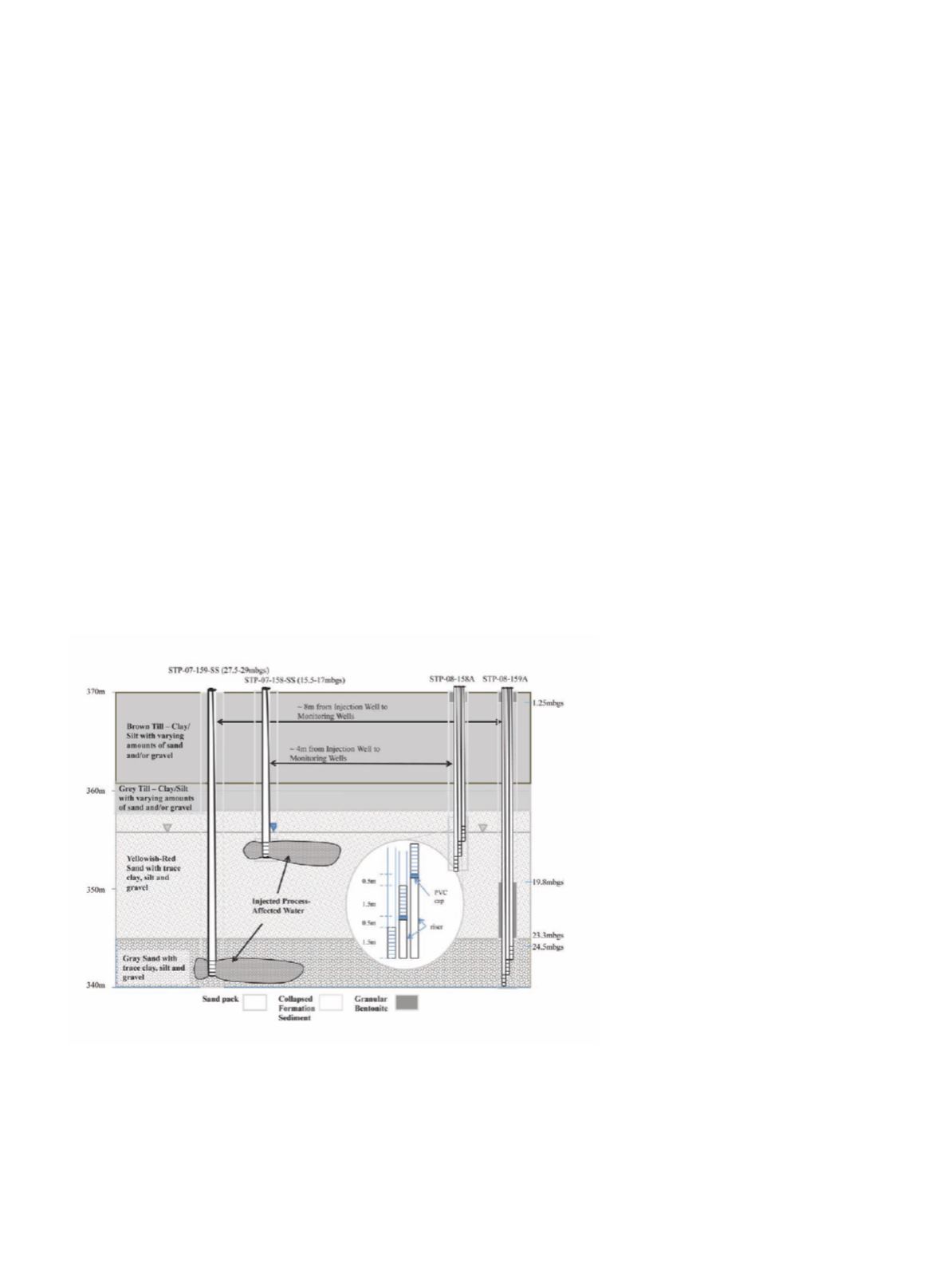

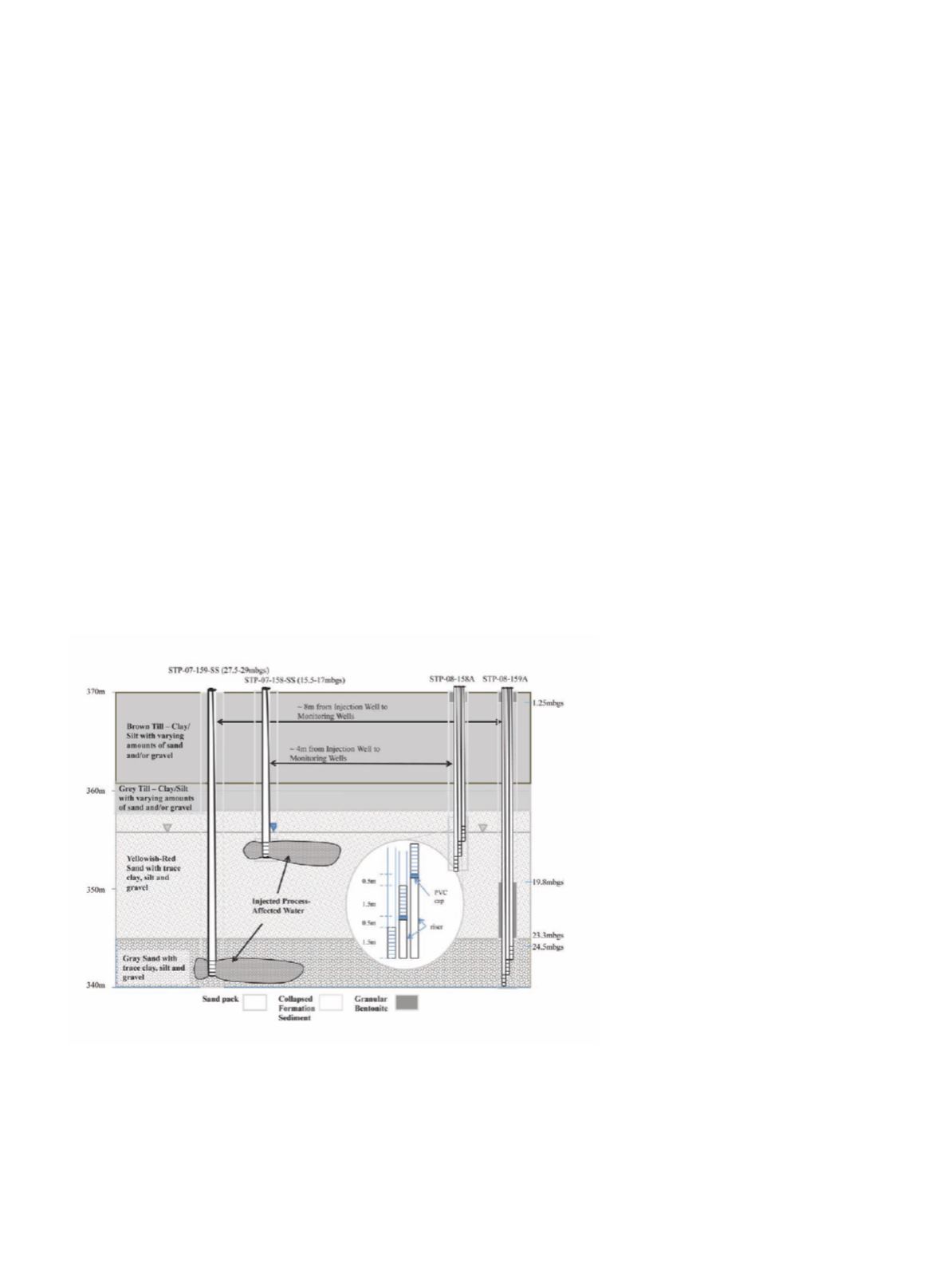

A nest of multilevel monitoring

points was constructed in June 2008, in

the estimated down-gradient direction

from each injection well (Figure 4).

These wells improve the researchers’

ability to identify local groundwater

flow direction and velocity and per-

mit study of injectate-aquifer interac-

tions over greater residence times. Nest

STP-08-158A was installed 3.7m from

STP-07-158-SS and STP-08-159A was

positioned 8.6m from STP-07-159-SS,

at an approximate bearing of 200 de-

grees S/SW from the injection wells.

Difficulty in precisely characterizing

local groundwater flow patterns pre-

cluded more distal placement of these

nests.

Injection and Sampling Well

Assembly

Each injection well is instrumented

with an inflatable packer, pump

and data logger to aid in the aquifer

injection experiments. A Schlumberger

CTD-Diver data logger continuously

records pre- and post-injectate

groundwater temperature, pH and

electrical conductivity. During injection

experiments, the Hoskin Scientific Ltd.

RST Instruments N-Packer is used to

seal the well screen from the overlying

stagnant water in the well and a

Grundfos Redi-flo2 submersible pump

is used to sample the groundwater.

Injections themselves are driven by

the ~15m difference in hydraulic head

between the discharging tank and the

water table. The components were

assembled in-house such that tubing

and wiring pass through the packer

(positioned just above the well screen)

to the probe and pump (aligned within

the well screen), thereby allowing

for samples and measurements to be

taken with the packer inflated and

in place. Lastly, each down-gradient

multilevel well is also equipped with a

Schlumberger CTD-Diver.

Continuous core samples were col-

lected within the Wood Creek Sand

Channel for grain size, falling head

permeameter, fraction of organic con-

tent, calcite and dolomite content, an-

aerobic microcosms, and sequential

extraction procedures (to assess the

partitioning of trace elements within

the solid phase).

Other Available Suncor

Facilities

Additionally, Suncor hasmadeavailable

to this project the use of pressure relief

wells at the toe of the dyke, internal

dyke drains and its own extensive

network of monitoring wells as well as

their historical sampling records. This

offers the project a means to further

corroborate and extrapolate findings

beyond the localized boundaries of the

three research facilities.

Conclusions and Outlook

In Northern Alberta, it is expected that

the placement of out-of-pit tailings

ponds atop permeable, glaciofluvial

sand channels will become increasingly

prevalent. This project is the first of

its kind to investigate the lifecycle

of process-affected water seepage

from an oil sands tailings pond in

this setting – beginning with in situ

background conditions, through to

seepage migration and evolution,

and culminating with preliminary

investigation into potential mitigation

strategies. This research is expected

to benefit the entire oil sands industry,

with ramifications extending to the

future placement of tailings ponds,

remediation and mine closure strategies

and legislation for environmental

compliance.

Acknowledgements

The authors wish to acknowledge

Suncor Energy Inc., NSERC, the

Alberta Innovates Technology Futures

and Klohn Crippen Berger Ltd. for

supporting this project.

Figure 4. Cross-section schematic of wells at the In Situ Aquifer Test Facility.

Each multilevel nest was instrumented with three, 2.5cm diameter, Schedule 40

PVC wells. Well screens were hand-slotted using a hacksaw and wrapped with fil-

ter fabric to prevent ingress of sand. To facilitate installation of each screen at the

target depth, a section of 2.5cm Schedule 40 PVC riser was subtended to the well

screen. A PVC cap was mounted between the base of the well screen and the riser

top, to prevent the accumulation of water in this section beneath the screen. (mbgs

= metres below ground surface, elevation (m) in metres above sea level)