22

Geotechnical News • June 2012

GEOTECHNICAL INSTRUMENTATION NEWS

eter (with sand-pack). In these cases,

information about the permeability of

the soil and grout is available.

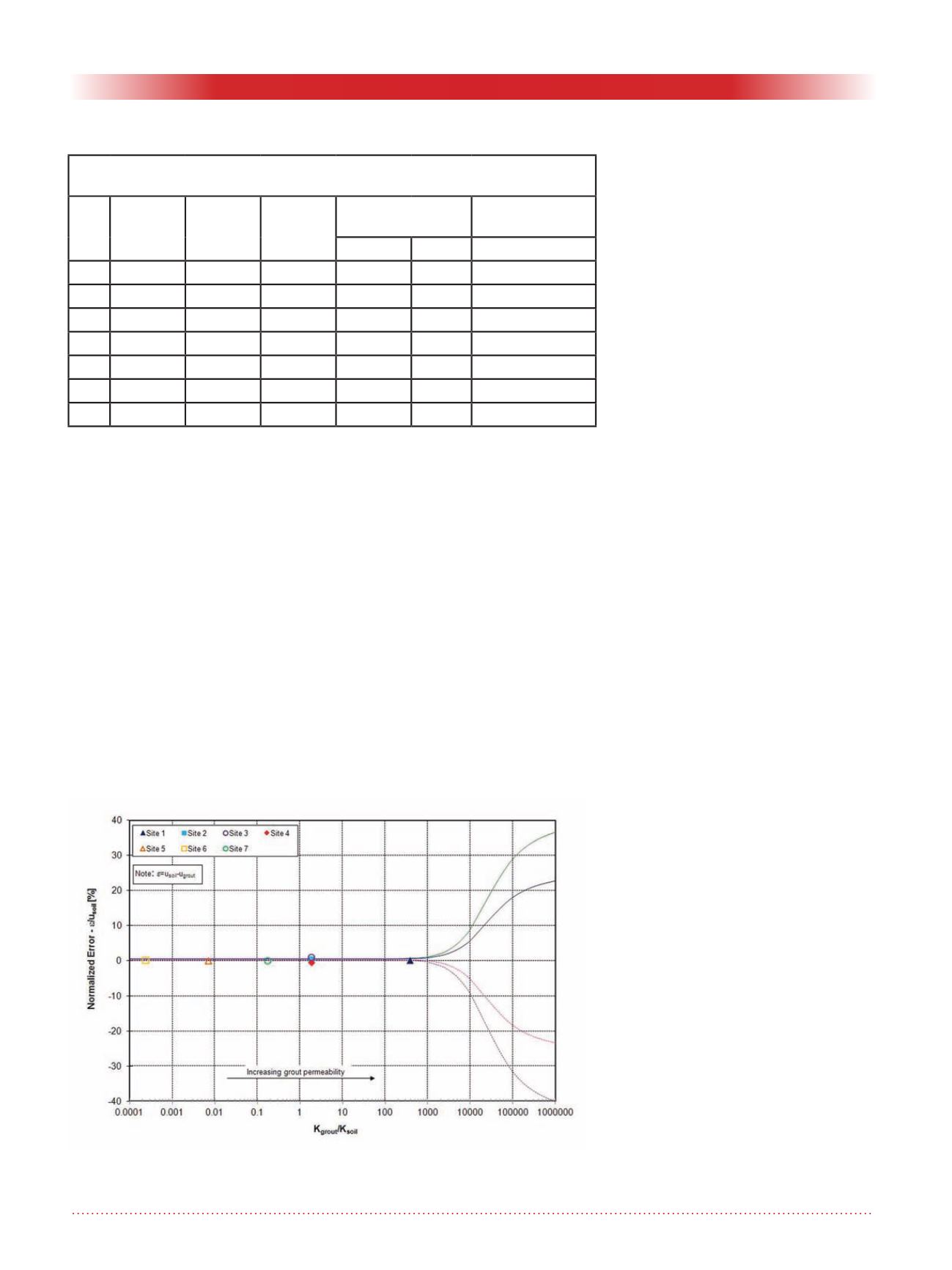

Table 1 summarizes the collected

data. The tips of the vibrating wire

piezometers (VW) included in Table 1

are within the same soil stratum as the

sand pack of the nearby open stand-

pipe piezometers (SP). While their

elevation is not exactly the same they

are close enough such that a similar

total head can be expected at both

instruments.

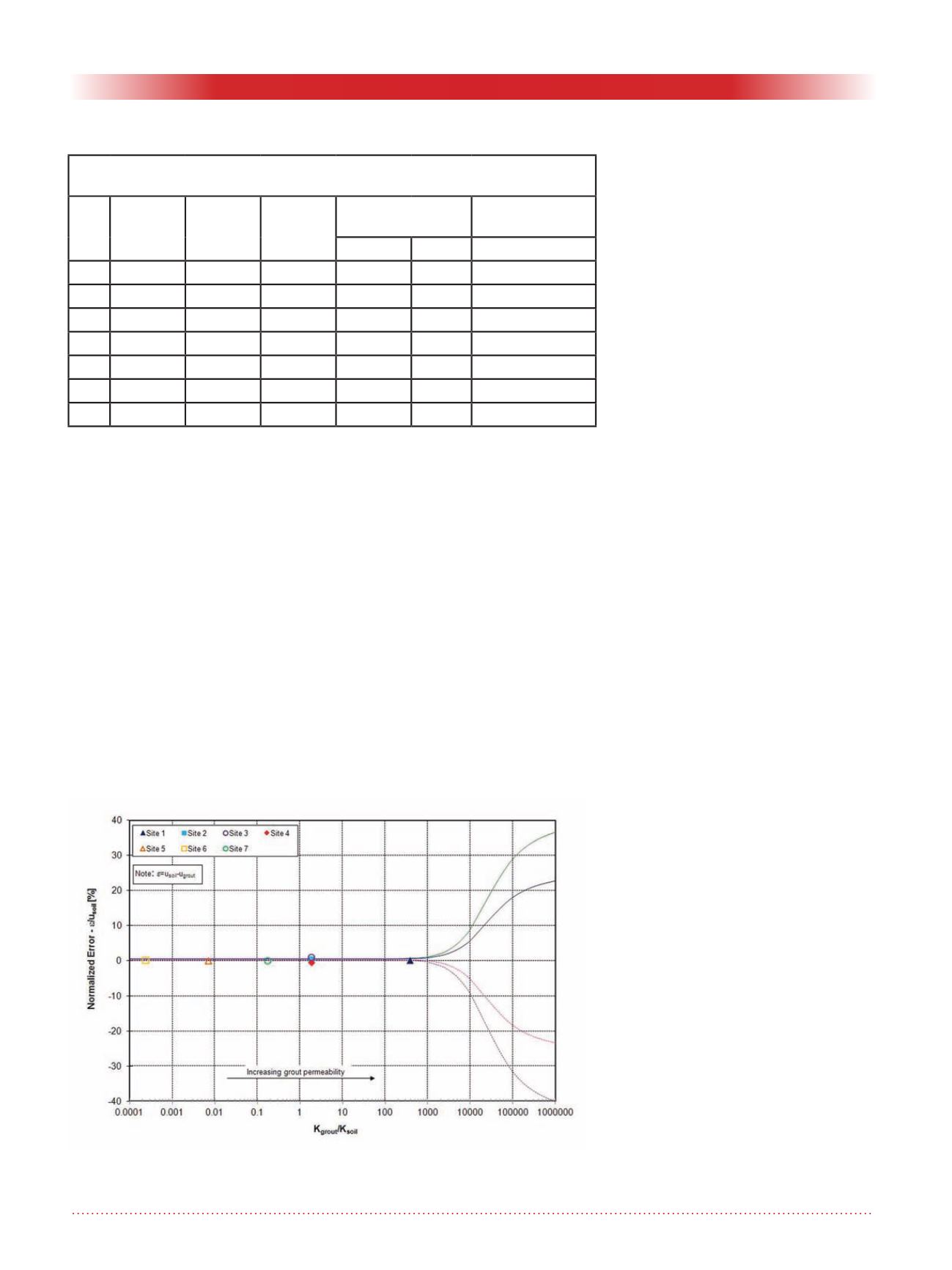

The data in Table 1 were used to

develop Figure 3, together with the

results of computer modeling that

were presented by Contreras et al.

(2008). The colored lines in Figure

3 are the summary of the computer

model results in terms of the error in

the pore water pressure measured as

a function of the permeability ratio.

The symbols in Figure 3 are the data

associated with the actual permeabil-

ity ratios and normalized errors from

Table 1. In developing Table 1, it was

assumed that the total head measured

in the open standpipe piezometers was

the actual total head. It can be seen

from Figure 3 that the measured and

predicted normalized errors are in

excellent agreement.

Installation in soft ground

During construction of embankments

over soft ground, monitoring typi-

cally includes measurement of pore

water pressures to track the consolida-

tion process as the excess pore water

pressure dissipation and settlement

take place. Because the fully-grouted

method allows for installation in a

nested configuration, it becomes very

attractive in this application. However,

two concerns have arisen, which might

compromise the correct performance

of the installations. First, the use of

a sacrificial grout pipe might result

in false data because of downdrag on

the grout pipe as vertical compression

proceeds. Second, will the column of

grout compress consistently with the

soft ground?

We have used the nested configuration

in several applications on soft ground

without any performance problems.

The following presents an example of

a nested fully-grouted installation in

soft ground.

The project consisted of construction

of a tailings dam on top of approxi-

mately 20 m of soft fine tailings/slimes

that were hydraulically deposited. The

fine tailings/slimes have a permeabil-

ity of 2.5x10

-6

cm/s. Three piezome-

ters were installed per borehole within

the fine tailings/slimes to monitor

the pore water pressure during fill

placement, and settlement plates were

installed to monitor settlement. Due

to the soft nature of the fine tailings/

slimes, the initial material placement

(i.e. working foundation) took place

during the winter months when a 1.2

m thick layer of frozen tailings forms

at the ground surface, allowing equip-

ment operation over the soft deposit.

After spring thaw and in the middle of

the summer, construction continued

by adding additional embankment

material.

Figure 4 shows the pore water pres-

sure and settlement data. Settlement

monitoring started when construc-

tion started. The piezometers were

installed 160 days after settlement in

Table 1: Comparison of total head from fully-grouted

and open standpipe installation

Site k (grout)

(cm/s)

k (soil)

(cm/s)

Kgrout /

Ksoil

Total Head

Measured

Normalized

Error (%)

VW (m) SP (m)

1 4.30E-06 1.12E-08 393.93 262.44 262.58

0.05

2 4.70E-06 2.50E-06 1.88

474.31 475.63

0.28

3 4.70E-06 2.50E-06 1.88

471.33 474.12

0.59

4 4.70E-06 2.50E-06 1.88

469.59 469.98

0.08

5 4.40E-06 6.24E-04 0.01

462.82 462.87

0.01

6 1.10E-06 4.58E-03 0.00

488.95 489.09

0.03

7 4.30E-06 2.50E-05 0.17

449.83 449.80

-0.01

Figure 3. Comparison of normalized errors (field and computer model)

with permeability ratio k

grout

/k

soil.