34

Geotechnical News • June 2012

THE GROUT LINE

resolve claims, and for future

reference on large projects that

will likely be subject to further

grouting).

The authors believe that the listed

applications of the data have the status

of “Principles” that we all agree apply

to grouting works. And these Princi-

ples have improved grouting – taking

rock fracture grouting as an example,

adding electronic monitoring systems

enables the industry to routinely grout

to a ~ 0.5 Lugeon standard today

versus something like ~ 2 Lugeons

thirty years ago, while using no more

than Type 3 cement, and at ~ 30% less

cost. So why the ruckus? We suggest

the cause is that while all grouting

engineers might agree on the above

three principles, there is no common

or accepted methodology to set about

meeting these principles, and further,

there exists a notion that being “pro-

prietary” provides both risk aversion

and competitive advantage. None of

the above, however, provides best per-

formance for the owner. And none of

the above is in the long term interest

of our industry.

Background to computer

monitoring

A reasonable starting point is to ask:

what are the standards/procedures in

the industry for monitoring of grout-

ing using computer-based digital data

acquisition? For the answer to this

question, let us accept that the four

New Orleans specialty conferences

indicate the state of the industry.

Using fractured rock as an example,

these conference proceedings show

that although electronic monitoring

started thirty years ago (e.g. Ref. 2)

there is still no consensus on what

needs to be measured or how those

measurements should be plotted/dis-

played. These differences stem from

different underlying idealizations

and so forth on how grout behaves.

The “GIN-sufficient” group (work-

ing from Ref. 3 as updated in Ref. 4)

are likely happy with a single plot of

pressure versus volume injected. The

“GIN-misleading” group (e.g. Ref. 5,

6) require pressure versus flow rate,

penetrability versus time, and pen-

etrability versus volume injected. Yet

others (following Ref. 7) might ask

for ‘Grout Lugeon’ plotted against

time. What we should all ask for,

but remains absent, is to add real-

time measurement of grout rheology

(although a good start at this was

discussed at the Conference, Ref. 8).

Perhaps surprisingly, the issues and

computer systems for monitoring

of compaction grouting are similar

to those of fractured rock grout-

ing. Largely driven by one extreme

application (Bennett Dam; Refs. 9,

10), it is now accepted that compac-

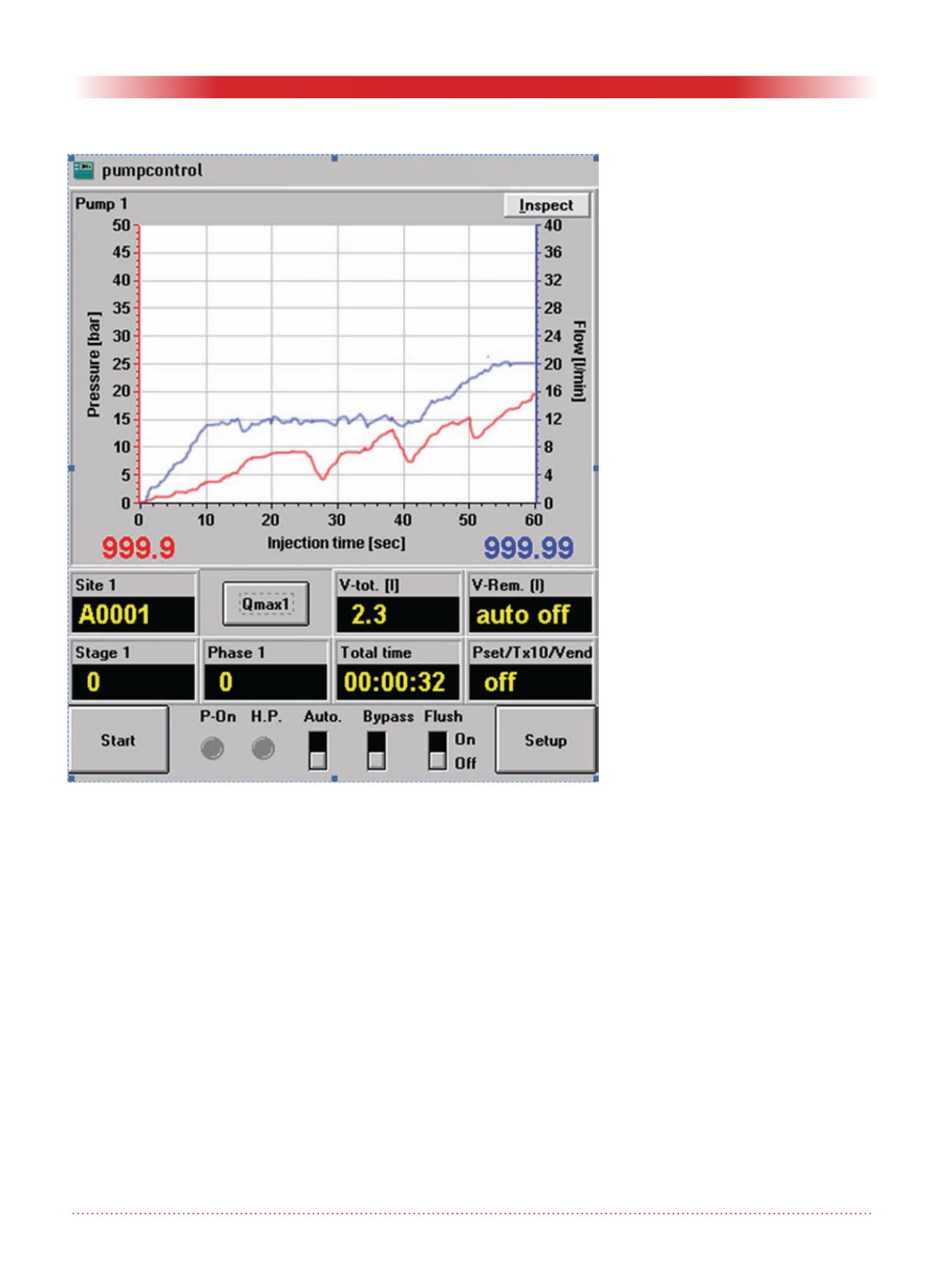

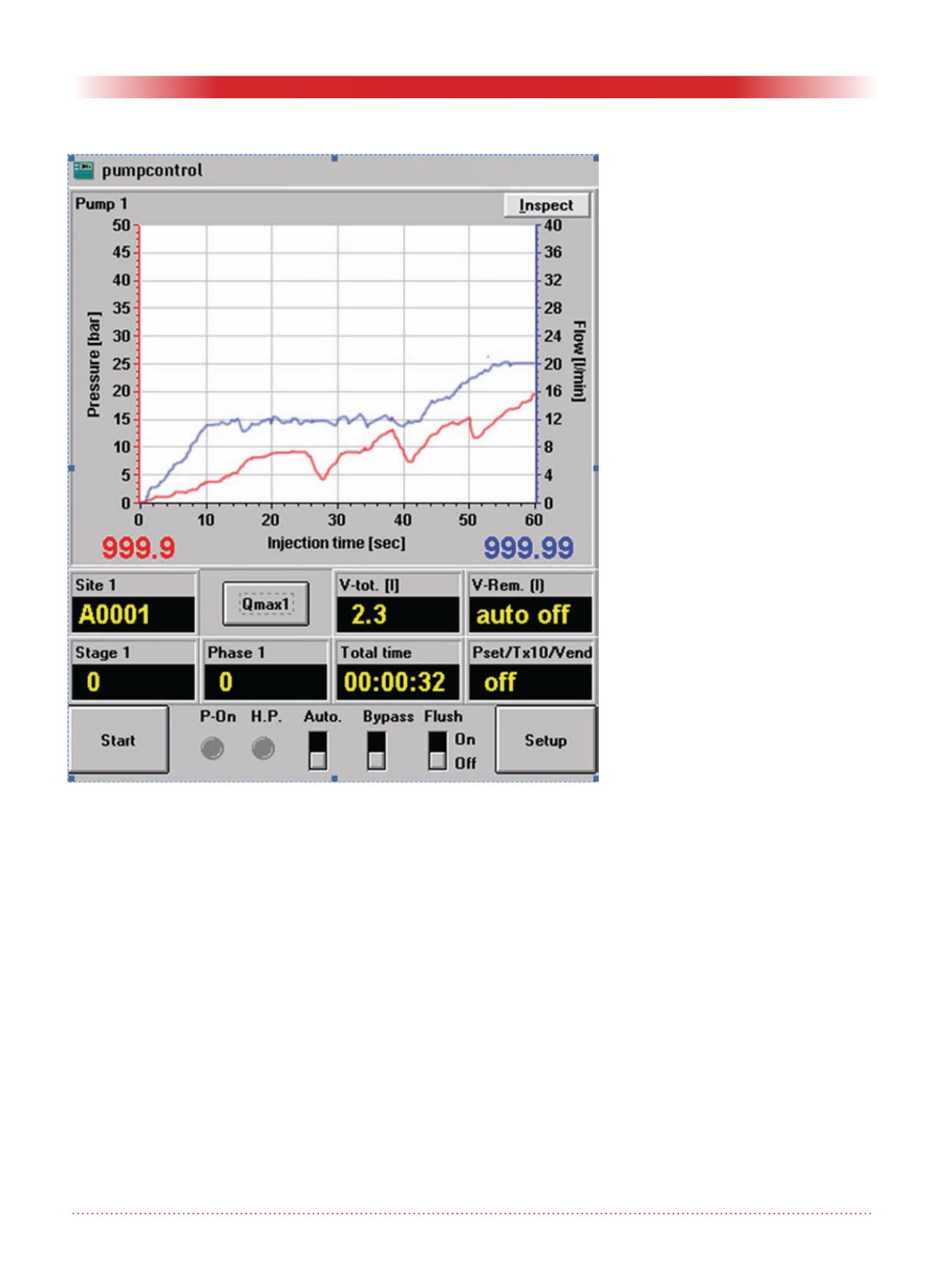

tion grouting should be monitored for

injection pressure, grout flow rate, and

total grout injected (Ref. 11).

Sorting out unusual

occurrences

The evolution of monitoring, from

the perspective of these New Orleans

conferences, shows good apprecia-

tion of the role of computers around

Principle 1. But the issues surround-

ing applying monitoring data to sort

out unusual ground response or grout

behavior – Principle 2 - has seemingly

not been discussed (or at least, we did

not find a single paper in our readings

of that literature). Here we offer some

examples where the ability to retrieve

data after grouting for further evalua-

tion has been important (if not crucial)

Grouting Sample.