Geotechnical News • June 2012

35

THE GROUT LINE

to the work’s success.

Bennett Dam: An extensive array

of piezometers had been installed

adjacent to the area to be grouted.

Maximum allowable pore pressure

increase had been established for each

piezometer, dictating the maximum

grout injection rate and resulting pore

pressure. Initial injection rate was

established based upon analysis and

experience, and should have been

sufficiently slow to not exceed the

allowable pore pressure rise. The real-

ity was, excessive pore pressure rises

occurred on several occasions requir-

ing cessation of all operations until

they were resolved. The recorded digi-

tal record was uploaded into Excel and

viewed at an expanded scale, to show

what was going on within a single

pump stroke. Substantial variation in

the rate at which the piston moved was

observed, even though the average

rate was as intended. The grout pumps

were then replaced with higher quality

pumps capable of uniform operation,

and the excess pore pressure problems

disappeared.

California Aqueduct: Internal erosion

and piping leakage of an embankment

on the California Aqueduct resulted

in an emergency grouting operation.

Time constraint limited the soils inves-

tigation to CPT probes, with this data

supplemented through close monitor-

ing of the injection behavior during

grouting. Each day’s computer moni-

toring data, again uploaded into Excel,

was analyzed overnight, distributed to

team members over the internet, and

injection parameters adjusted for the

following day’s work. Upon comple-

tion of the emergency work, the data

was used to better understand the

existing conditions, facilitating future

action consideration.

Colorado Oil Shale: A perimeter grout

curtain was intended as a component

for environmental isolation of in situ

recovery of hydrocarbons from the

shale. However, initial operations

viewed the ground as ungroutable

with reported observations that grout

“ran away into the formation”. This

project involved greater than usual

depths (more than 400 m working

from surface). Grout data was recov-

ered from the data acquisition system

and uploaded into Excel for detailed

analysis. The following situation was

revealed. Grouting started with water-

filled tubing, and as grout travelled

down the tubing the collar pressure

dropped dramatically because of the

weight of the grout, until the water in

the grout cavitated with consequent

loss of flow control – the reported “run

away” into the formation. The situa-

tion became controlled once sufficient

grout had penetrated the formation to

build enough hydraulic drag to return

the collar pressure to less than that

allowing cavitation of the grout. Excel

analysis of the data determined low

density, high viscosity grouts were

needed for the project.

Amtrak Bridge: This project involved

Computer contol room.

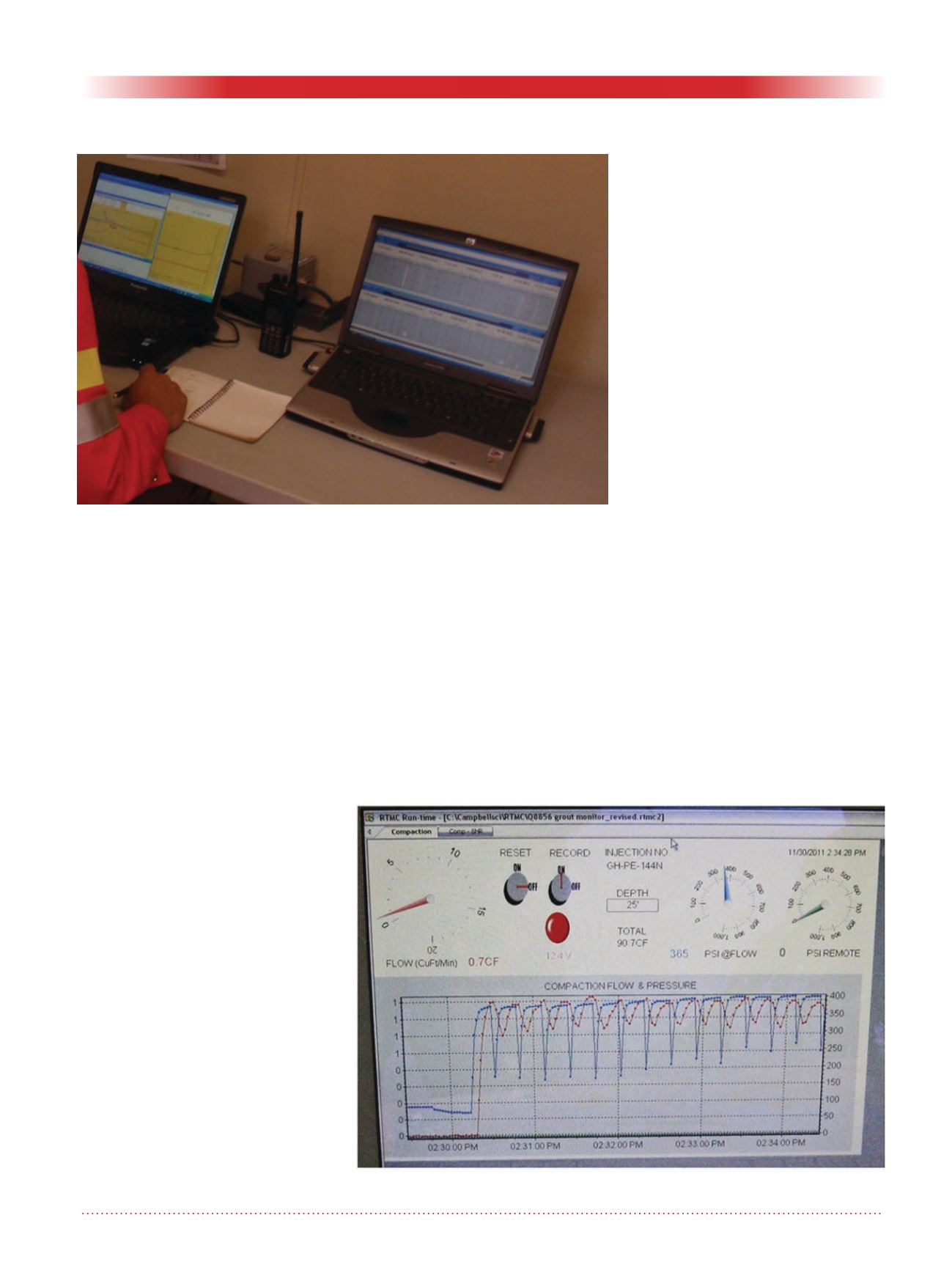

Compaction recording.