Basic HTML Version

www.geotechnicalnews.com

Geotechnical News • December 2012

43

THE GROUT LINE

Use of the real time monitoring for micropile/

anchor testing and stressing

Paolo Gazzarrini P.Eng.

Abstract

The use of computers and real time

monitoring in the grouting industry

has become very popular, useful

and nearly mandatory in the last two

decades. Can we say the same for the

micropile/anchor industry?

This paper will describe some pre-

liminary tests carried out in micropile/

anchor projects in Vancouver, Canada,

with the use of commercially available

instruments, recording in real time the

testing and stressing of the micropiles/

anchors. The system used allows

recording and printing in real time the

behaviour of the micropiles/anchors,

to automatically create movement/load

graphs in performance tests, creep

tests and proof tests.

In the tests that were carried out the

system proved reliable, indicating a

great opportunity for the micropile/

anchor industry to increase its level of

quality control and quality assurance.

Introduction

Testing of micropiles (tension/com-

pression/lateral) and anchors (tension)

follow very strict standards and accep-

tance criteria. Literature for testing is

available, for example, in:

• FHWAMicropile Manual

• FHWA Ground Anchors and An-

chored Systems

• PTI Recommendations

• Eurocode 7

This paper does not analyze/discuss

the different kinds of tests (ultimate,

verification, proof or creep) or the

acceptance criteria, but only the appa-

ratus used and results obtained in a

couple of preliminary tests carried out

in Vancouver.

Conventional testing

What is used generally for micropile/

anchor testing?

• Hydraulic jacks,

• Dial Gauges,

• Load cells (sometimes),

• Reaction anchors/ frames for com-

pression test.

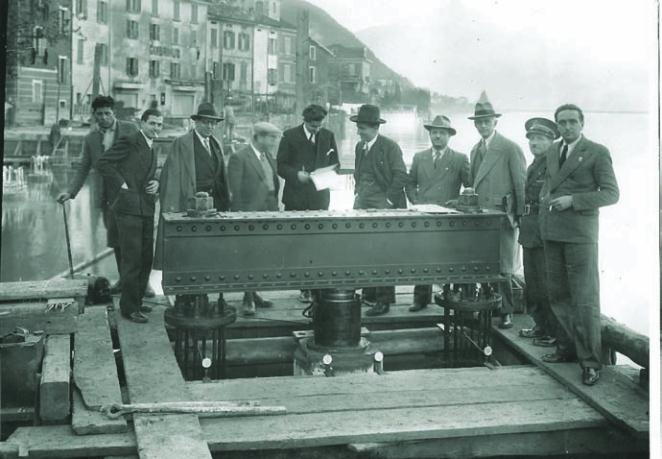

What is the difference between a load

test done in 1947 (see picture #1 ) and

a test done today?

The same, or similar, dial gauges,

same hydraulic jack, sometime today

also with a hand pump, a shiny steel

beam (I doubt today!), shine and

elaborated reaction anchors. Not much

difference today, 65 years later! The

only notable difference from today

is, definitely, the approach to safety

(please note the picture), much dirtier

shoes and a slightly different fashion

on site!

Monitoring of the testing in real

time

So, what can be done today to increase

the level of QA/QC in testing micro-

piles and anchors?

The use of computers and real time

monitoring in the drilling and grout-

ing industry has become very popular,

useful and nearly mandatory in the last

two decades. Electronic instruments

are now available on the market that

allow the monitoring, recording and

plotting of tension/compression tests

in micropiles/anchors in real time.

The apparatus used for the test in Van-

couver is composed of:

• Main recording unit with printer,

keyboard and electrical junction

box. See picture #2.

Picture 1. Compression test done in 1947 at Campione d’Italia (Lugano

Lake).