Basic HTML Version

34

Geotechnical News • March 2014

www.geotechnicalnews.com

GEOTECHNICAL INSTRUMENTATION NEWS

others, but hard data makes for a more

compelling case.

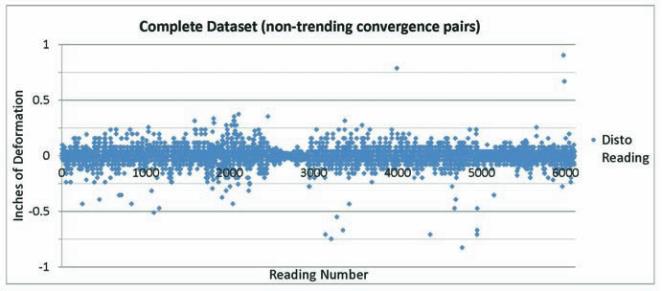

From 2007 to 2012, more than 8,000

laser-distometer readings were col-

lected at the East Side Access Project

between 310 tunnel and cavern defor-

mation point pairs. Readings in the

tunnels were collected immediately

behind the tunnel boring machines

between targets installed on virgin

rock, and readings in the caverns were

recorded immediately following exca-

vation by drill and blast.

The data collected were analyzed to

validate the suitability of the laser-dis-

tometer as a replacement for the tape

extensometer. To evaluate the suit-

ability, all erroneous data (anchor bolt

damaged or destroyed) was removed

from the dataset, and all point pairs

indicating trending data (deformation

is occurring) were removed. This left

a “stable” dataset of more than 6,000

readings between 245 deformation

point pairs (Figure 4). The intent of

reducing the complete dataset to a

“stable” dataset is to analyze the laser-

distometer as a measurement tool,

rather than analyze the actual defor-

mation that may have occurred.

Results of the program and

conclusions

The scatter in the stable dataset plotted

as a histogram is an excellent approxi-

mation of the normal distribution.

Therefore, by calculating the mean

and standard deviation of the stable

dataset, it follows that 93.1% of read-

ings fall within the three millimeter

manufacturer specification of instru-

ment precision.

In reality, random errors are intro-

duced into the measurement process

by the operator. Assuming that random

errors by the operator introduce an

additional one-millimeter of error into

the readings, it follows that 96.3% of

readings fall within the instrument

specifications, and if two millimeters

of random error are introduced, then

99.8% of readings fall within the

instrument specifications.

The most significant random error

to be mindful of is “pointing” error,

whereby the laser beam is reflected

from different points on the second

target during successive readings.

Other random errors may be intro-

duced into the readings when the

laser-distometer is not snugly fitted

into the cradle, or when excessive dust

within the tunnel causes refraction of

the laser beam.

The laser-distometer has met the

requirements for deformation monitor-

ing at the East Side Access Project,

and has proven to be a viable alterna-

tive to the tape extensometer. Under

ideal conditions, it is possible that the

tape extensometer may yield defor-

mation readings of higher precision,

however this comes at a consider-

ably higher cost, both in material and

labor. Where project-specified limits

of movement allow for the substitu-

tion of a laser-distometer for the tape

extensometer, the option should be

seriously considered.

Chris Fagan

Geocomp Engineering, 139 Fulton

Street, Suite 917, New York, NY 10038.

Tel: 646-831-8941.

email: cfagan@geocomp.com.

Charlie Daugherty

Parsons Brinckerhoff, One Penn

Plaza, New York, NY 10119.

Tel: 212-465-5451,

email: daugherty@pbworld.com.

Commercial sources:

Leica Geosystems – laser-distance

meters

Leica Disto A3 (used for monitoring

at East Side Access described in this

article)

Trimble – laser-distance meter

Tape Extensometer

Slope Indicator -

Geokon -

ITMSoil -

RST -

Figure 4. Laser- distometer dataset.