Basic HTML Version

www.geotechnicalnews.com

Geotechnical News • March 2014

49

THE GROUT LINE

and the time spent on grouting after

the stipulated time. Not even unfilled

boreholes should be reimbursed for.

The risks were too high and it was

never conducted.

The most efficient way for the engi-

neer and owner according to Scandi-

navian experience is to secure control

with performance and cost related

to pre-grouting is to obtain qualified

estimates in the Bill of Quantity at

the tender stage and to re-measure

all grouting related activities during

tunnelling excavation. Such conditions

need to be reflected in the construction

contract. A guideline for compensation

units would be as follows:

• Probe drilling ahead of tunnel face

– re-measured and reimbursed by

drill meter

• Drilling for grouting – re-measured

and reimbursed by drill meter

• Grout packers - re-measured and

reimbursed by piece

• Grout materials – re-measured and

reimbursed by kg for all materials

• Grouting time – re-measured and

reimbursed by hours used for

grouting

To compensate for actual consumption

of time and materials for grouting may

sound risky for many project own-

ers. However, specifying minimum

capacities on machinery and by setting

minimum contractual production

rates the owner has tools making him

capable to control volume and cost of

pre-grouting works. Experience from

Norwegian view is as follows:

à

à

Design before contract, details

to be decided during the tunnel-

ing progress

à

à

The amount of cement governs

the sealing effect

à

à

Opening of fractures is seen as

a risk but could improve the

grouting works

à

à

Experience from Swedish point

of view is:

à

à

Design before contract, not

always

à

à

The amount of boreholes and

type of grout governs the sealing

effect

à

à

Opening of fractures often seen

as negative and as a risk

Discussion and conclusions

Sealing effect and tight enough?

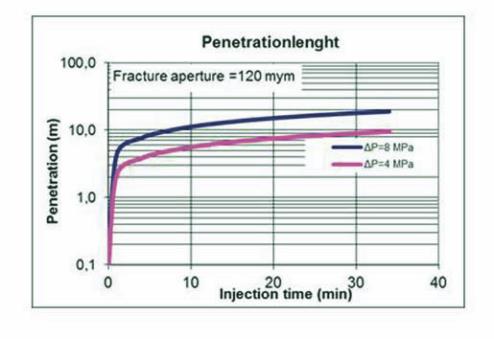

The penetration length is directly

proportional to the applied pressure,

the fracture aperture and inversely

proportional to the viscosity and

yield strength. A doubled pressure

will increase the penetration length

to the double. In Figure 3 below the

penetration length is calculated using

the equations in (Gustafson and Stille,

2005) where the

grouting time is incorporated to deter-

mine the penetration length. In the

example the over pressures are 4 and 8

MPa respectively, the yield stress are

3 Pa and viscosity= 0.025 mPas. The

fracture aperture is set to 120 µm.

For infinite time the final penetration

for a pressure of 4 and 8 MPa are 80

and 160 m, respectively. For 30 min-

utes of grouting the difference is 9 and

18 m, respectively. We can see that the

penetration length is long and fast for

the first 3 minutes and after that gradu-

ally slows down.

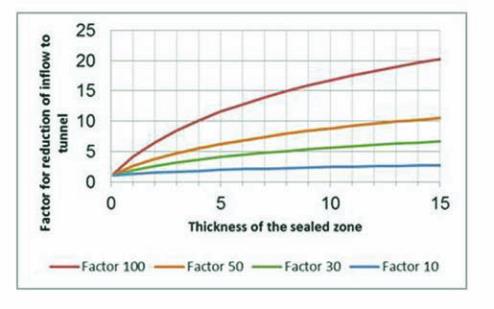

Both the tightness (transmissivity) and

the extent (thickness) of the sealed

zone influence the ingress to a tunnel.

For instance, a very tight sealed zone

with a low extent is comparable with a

large zone with less “tightness”.

From the figure below (Figure 4) one

can see that the reduction of ingress

to the tunnel is strongly correlated to

the thickness of the sealed zone for

sealing factors of 50 or more. This

means that if the grouting can be done,

assuring that the transmissivity of the

rock mass is lowered by at least a fac-

tor of 50, the thickness of the sealed

zone can be used for prognosis of the

ingress. The thickness can be inter-

preted to a grout spread, large grout

spread mean a larger thickness of the

sealed zone.

Figure 3. A diagram showing the difference in penetra-

tion length using an overpressure of 4 and 8 MPa in a

fracture aperture of 120 µm.

Figure 4. A diagram showing the reduction of inflow to

the tunnel correlated to the sealing factor and the thick-

ness of the sealed zone. The tightness or how permeable

the sealed zone is described by the sealing factor. For a

sealing factor of 100 mean that the sealed zone has 100

times lower transmissivity than the surrounding rock.