Basic HTML Version

50

Geotechnical News • March 2014

www.geotechnicalnews.com

THE GROUT LINE

For tunnels with high inflows and very

strict demands (< 2 l/min), say urban

tunnels a tight grouting fan (high seal-

ing factor) together with thick sealed

zone is required (see Figure 4 above).

Achieving both these requirements are

though resource demanding.

Summarizing the above; water ingress

to a tunnel can be reduced by either

penetrating grout deep into the rock

mass, hence using a large grouting

pressure to produce a thick sealed

zone or by applying lower grout pres-

sure but with a tight grouting fan (high

sealing factor). One can say that the

ingress by only elaborating round the

thickness of the sealed zone is limited

but for some tunnels adequate enough.

From this point of view it looks like

the Norwegian style is to produce a

large thick zone and the Swedish way

is to get a high sealing factor and that

the Swedish approach is much more

based on theoretical background than

the Norwegian which is a typical

empirical approach with high confident

in using experience based grouting.

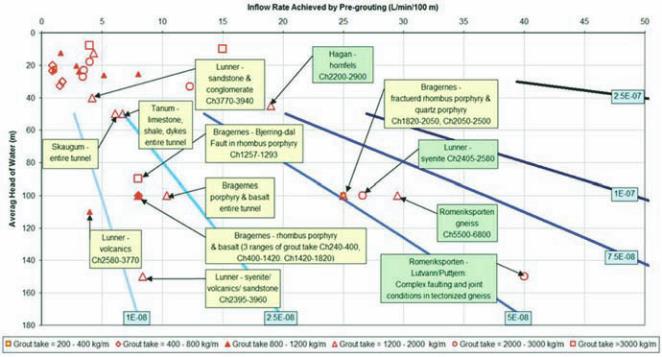

In recent years, tunnel inflow rates

as low as 2 L/min/100 m have been

specified and achieved in Norway

(Grøv, 2008b) and (Tattersall et al,

2009). Data for land-based tunnels

have been summarized in Figure

5 below. It shows the groundwater

inflow rates achieved by pre-grouting

and the average grout takes plotted

against the average head of water for

different tunnel segments. Correlation

lines which show trends in theoretical

inflow rates for uniform un-grouted

rock masses with different hydraulic

conductivities are shown on the plots

for comparative purposes. These have

been calculated from an equation for

deep, un-grouted tunnels given in

(Dalmalm, 2004) for a typical 10 m

diameter tunnel (79 m2 cross-sectional

face area). For example, a uniform

rock mass with a hydraulic conductiv-

ity of 5 x 10-8 m/s could be expected

to yield an average groundwater

inflow of about 25 L/min/100 m at

100 m depth. However, it should be

noted that the hydraulic conductivity

in the grouted zone needs to be much

less than the surrounding rock mass

in order to give an apparent overall

effective conductivity of 5 x 10-8 m/s

if the surrounding rock mass has a

much higher hydraulic conductivity.

For example, the data points for the

Bragernes tunnel between Ch1820 and

Ch2500 shown in Figure 2 imply that

the natural hydraulic conductivity of

the rock mass is much higher than 5 x

10-8 m/s and that the hydraulic con-

ductivity achieved in the grouted zone

must be much lower. The grout take of

1911 kg/m length of tunnel shown in

Table 1 for Ch2050-2500 confirms that

relatively intensive grouting efforts

were necessary to reduce the inflow

rate in this section of the tunnel.

The groundwater inflow limit targets

for land-based tunnels are shown in

chapter 3.1 above, whilst for sub-

sea tunnels in Norway, the typical

groundwater inflow rate target is 30 L/

min/100 m. Figure 5 is a collection of

different cases being gathered where

experience data has been provided.

The calculated rock mass permeability

is shown with diagonal lines, whilst

achieved inflow rate is plotted against

water head and consequential grout

take is shown with various symbols

(see key underneath the figure). Cases

where the measured groundwater

inflow rate exceeded the inflow rate

target are highlighted in green. For

both land-based tunnels and sub-sea

tunnels there are no data where the

inflow rate specified or achieved is

greater than 50 L/min/100 m (the

upper limit of the graphical plots

shown in Figure 5). For land-based

tunnels, about 50% of the inflow rates

achieved are less than 15 L/min/100 m

and in all cases but one the inflow

rates are less than 30 L/min/100 m. It

can be concluded based on Figure 5

that the grout take is difficult to assess

based on even factual parameters

as water head and inflow rate. The

historical case of Romeriksporten is

well known (Beitnes, 2002) and does

not provide an example of what is now

normally achieved. The case provided

much incentive for the development of

the better grouting strategies that now

form Norwegian state-of-practice.

In the case of sub-sea tunnels, there

are some examples where the overall

inflow rates exceeded 30 L/min/100 m,

but these tunnels were completed

between 26 and 13 years ago when

grouting practice was much less devel-

oped and groundwater inflow rates

may not have been as strictly enforced

as they are today. The more modern

sub-sea tunnels all show inflow rates

equal to or less than 30 L/min/100

m. Even in the basaltic rocks of the

Nordic region which are commonly

highly permeable, (Grøv & Nilsen,

Figure 5. Norwegian Examples of Inflow Rate Achieved and Grout Take for

Pre-grouted Land-based Tunnels.