Basic HTML Version

www.geotechnicalnews.com

Geotechnical News • September 2014

37

THE GROUT LINE

was further increased to 17 m, with a

5.5 m overlap of the second campaign.

This time both drilling and grout-

ing were performed in two different

stages; up to 9 m for the first, and up

to 17 m for the second. The campaign

was completed in 2 months.

3rd Campaign - Technical data:

• Number of holes drilled: 101

(Including re-drilled + different

stages)

• Total length drilled: 1,246 m

• Total quantity injected: 294 m3

• Volume injected: 236 l/m

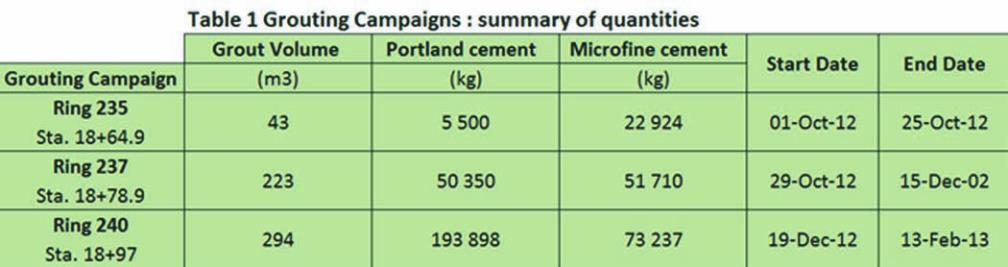

A summary of the three grouting cam-

paigns is shown in Table 1.

After completion of the third cam-

paign, on February 19, 2013 a perme-

ameter test was performed to reach 0

bar of pressure. This is the first time

we were able to lower the face pres-

sure to atmospheric conditions. The

overall water inflow was reduced from

1,100 m3/h (290 gal/h) to 220 m3/h

(587 gal/h), and a face inspection was

accomplished. Even if the total water

inflow was reduced however, the over-

all stability of the tunnel face was not

completely safe.

Under such hydro-geological condi-

tions we were able to perform the

following maintenance and repairs:

• Full cutter head inspection

• Changed 4 cutters

• Cleaning of the cutter head open-

ings

• Replaced level sensors in the work-

ing chamber

• Maintenance on the compressed air

line (SAMSON)

• Free the stone crusher and the

working chamber from the grout-

ing injected during the three

campaigns

The most important activities were

the replacement of worn pipelines,

valves, pumps and the installation of

a new hydraulic valve on the slurry

return line just behind the suction pipe

in the drilling chamber, which became

an additional safety device in case the

pipe would burst.

When maintenance was completed,

the TBM was able to advance forward

through the fault area and reach a zone

with better hydro-geological condi-

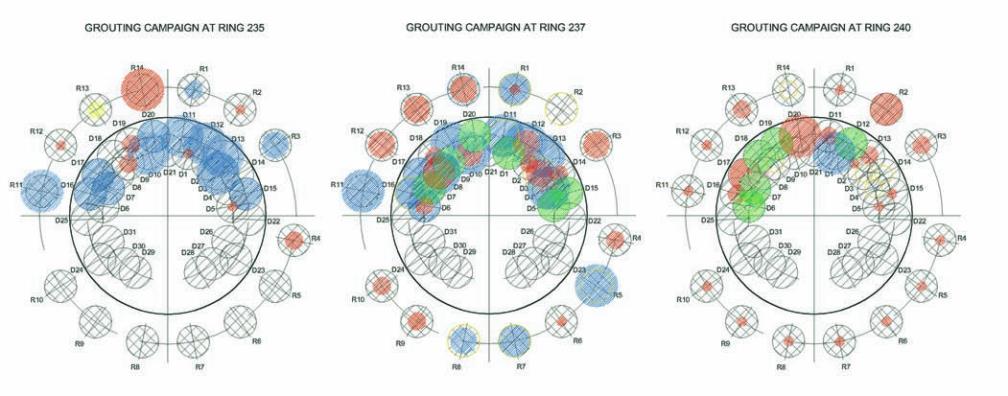

Figure 7: Grouting campaigns.