Basic HTML Version

www.geotechnicalnews.com

Geotechnical News • December 2014

31

THE GROUT LINE

between pairs of columns. Moreover

it allowed for the calculation of the

starting coordinates of a possible addi-

tional column, in case the target was

not reached.

The data contained in the database

were used to create the 3-D model of

the installed columns. Starting from

the model, a plan view with four

transverse sections and a longitudinal

section for each section was created.

A 3-D drawing was created for each

compartment, allowing the extrapo-

lation of some sections at different

depths.

Final control and results

The final controls were focused

on assessing the strength of the jet

grouting bodies, and the final perme-

ability. To this end, corings were used

to collect samples to be tested for

crushing tests, and pumping tests were

performed to measure the resulting

quantity of water.

As said, the design was asking for

a minimum uniaxial compressive

strength of 5MPa: the tests gave a

minimum strength of 8MPa.

The compartments were all success-

fully tested using pumping tests. The

average water flow was measured in

2.5 liters per second (compared to the

5 liters per second tolerated by the

design).

Conclusions

The method proposed by Trevi

enabled the achievement of the desired

features in terms of water tightness

and strength requested by the design.

In spite of the complex geology,

where the groundwater was running

at high velocity, the excavation of the

tunnel 20 m below water table and 32

m below grade, has been performed

safely without major difficulties, in

dry conditions.

Last but not least, to be noticed that

the railroad was continuously operat-

ing 365/7/24 during the execution

of the jet grouting works with only

a slight reduction in the speed of the

trains. For safety purposes, potential

movement of the railroad tracks were

monitored in real time and no issues

were observed during the execution of

the jet grouting works.

References

Greeman, A., 2009:

Cutting through

Austria’s Inn Valley

. Tunnels &

Tunnelling International, Novem-

ber, pp.16-19.

AA.VV., 2010:

From the ground

down

. World Tunnelling, March,

pp.10-11

And, as usual, the same request,

asking you to send me your grouting

comments or grouting stories or case

histories. My coordinates are:

Paolo Gazzarrini,

,

or

Ciao! Cheers!

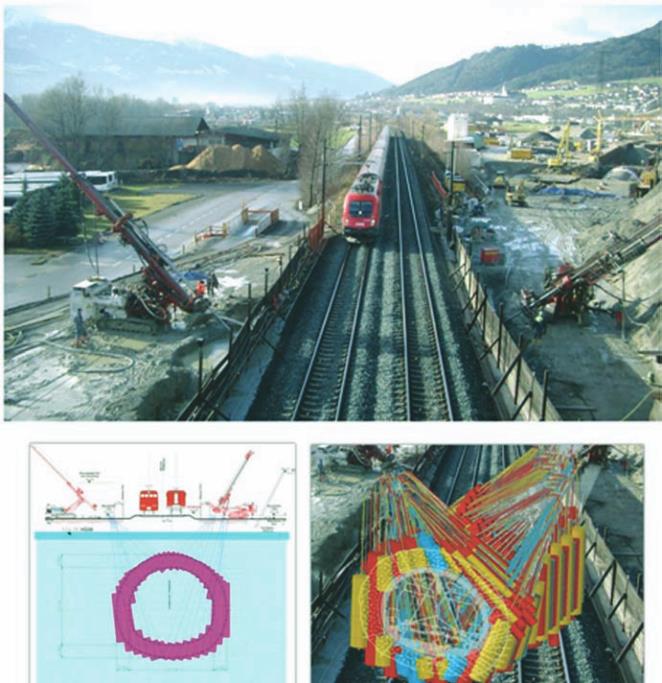

Figure 5. Panorama of two rigs working on the two sides of the existing

railway line. At the bottom, the cross section (left) and a 3D view of the final

shell created by the jet grouting (right).