Basic HTML Version

40

Geotechnical News • December 2014

www.geotechnicalnews.com

GEOTECHNICAL INSTRUMENTATION NEWS

was a viable, and typically superior,

alternative.

[I’m concerned about this apparent

green light for installation of pneu-

matic piezometers by the fully-grouted

method. There are several types of

pneumatic transduces, including those

that are read as gas is flowing past the

diaphragm and, very preferably, those

that are read under a condition of no

gas flow immediately after the flow is

stopped. In the latter case a volume

change occurs in the pore space at

the instant of reading (red book Sec-

tion 8.3). I’ve always contended that

this feature negates the use of the

fully-grouted installation method for

installation of pneumatic piezometers.

I made this point to the author of this

article, who replied: “With respect to

the diaphragm displacement issue with

the pneumatic transducers, we can

create a situation where the pressure

response oscillates as the diaphragm

opens and closes (but gradually con-

verges on a stable reading) if we cast

the transducer without a filter tip. With

a filter tip, we have never experi-

enced that type of oscillation – out of

several hundred installations. We have

read the grouted-in-place pneumatic

transducers both ways – with a slow

constant air flow through a needle

valve and by over-pressurizing the tip

and allowing the pressure to drop and

stabilize – both yield the same results

within about an inch of water col-

umn”. Despite this reply, I’m reluctant

to change my contention and support

the green light.

Does anybody have

anything to contribute to this?

J.D.]

Sub-slab vapor barriers

The second case involves the moni-

toring of soil gas sampling probes

installed above a sub-slab vapor

barrier. Engineered vapor barri-

ers are frequently installed beneath

buildings that are constructed at sites

where Volatile Organic Compounds

(VOCs) such as solvents, gasoline,

or other hydrocarbons are present

in the subsurface. The barriers are

intended to reduce the rate at which

VOCs would otherwise migrate to the

interior air spaces of buildings. Post-

installation monitoring and evaluation

of the performance of sub-slab vapor

barriers is becoming an increasingly

common requirement at contami-

nated properties. Soil gas sampling

probes are often installed above and

below a vapor barrier to confirm that

it is functioning as expected. There

is a common perception that vapor

concentrations above a barrier should

be very low - if not below detectible

levels. The presence of elevated

vapor levels in the space above a

vapor barrier and below a floor slab

is frequently taken as an indication

that the barrier is not functioning

properly. This interpretation is not

necessarily correct. All vapor barriers

will transmit VOCs to some extent.

The purpose of the barrier is to limit

the rate of VOC transmission to the

interior of a building such that accept-

able risk thresholds are not exceeded.

High quality, intact concrete also

provides considerable resistance to the

transmission of many organic vapors.

Although a concrete floor slab can

typically not be relied upon to func-

tion as a vapor barrier for a number of

reasons, the characteristics of the floor

slab need to be considered when data

from sub-slab vapor probes is to be

used to evaluate the performance of an

underlying barrier.

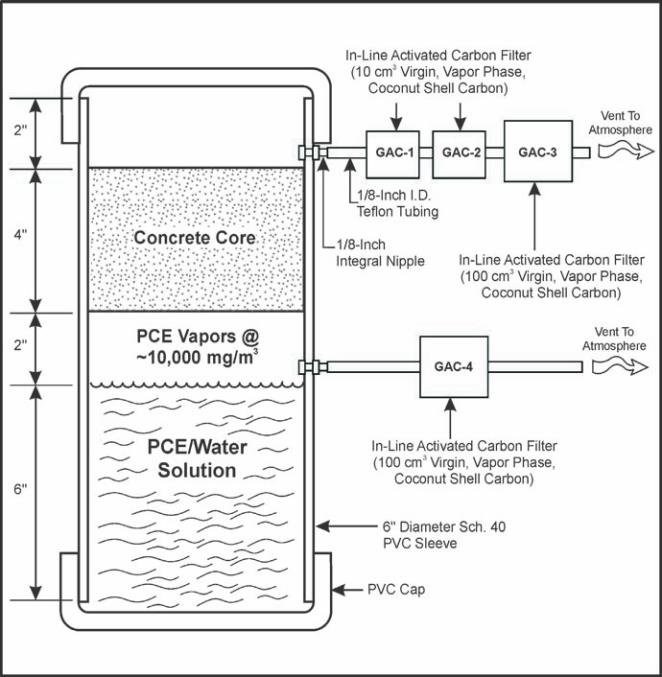

The diffusion coefficients for a num-

ber of vapor barrier materials have

been measured for various VOCs

using the test configuration illustrated

in Figure 2. Similar tests have been

performed to measure the vapor diffu-

sion coefficients for concrete (Figure

3). As shown, for both the membrane

and concrete tests, a water reservoir is

maintained in the lower test chamber.

VOCs are dissolved in the water to

Figure 3. Concrete slab diffusion test configuration.