18

Geotechnical News •June 2015

GEOTECHNICAL INSTRUMENTATION NEWS

80 mm to 200 mm. The rockfill shell is

comprised of two zones: the 3O inter-

nal shell has a maximum allowable

size of rock particles of 0.6 m com-

pared to 1.2 m for the 3P outer shell.

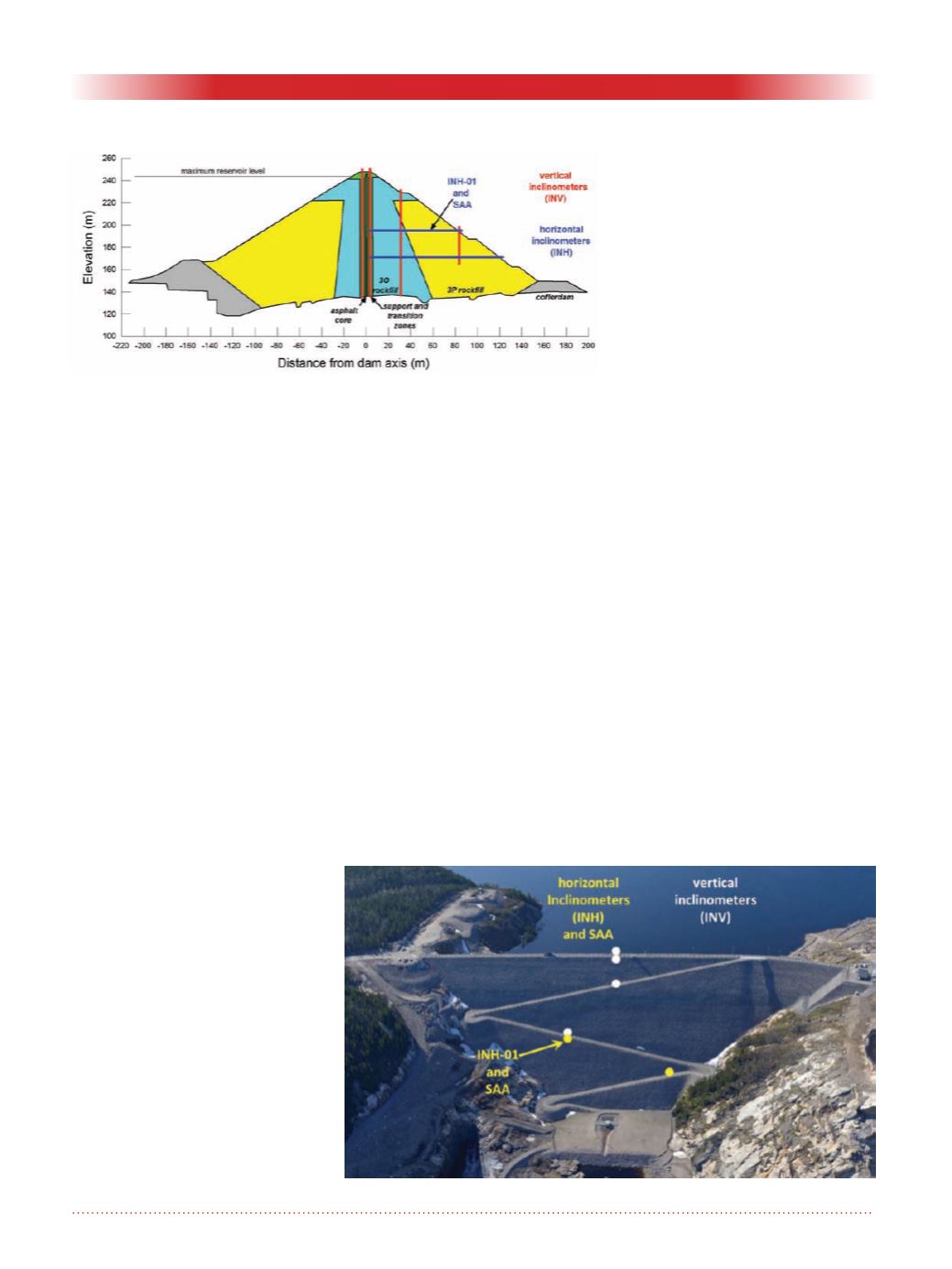

Figure 1 shows a schematic cross sec-

tion of the dam at valley center.

Material placement procedures were

of utmost importance to prevent

excessive fill movements during dam

construction and operation which

could have detrimental effects on the

thin asphalt core. The placement of

support/transition as well as rockfill

zones required optimized material

characteristics and increased com-

paction energy to achieve maximum

density and thus minimize settlements

during construction, impoundment

and operation. Therefore, internal

deformations of the dam needed to be

closely monitored to assess its behav-

iour as well as in situ materials rigidity

parameters to be used for stress/defor-

mation modelling and also to quantify

the effects of the increased compac-

tion energy used for the Romaine-2

dam compared to other Hydro Québec

projects.

A series of inclinometers is installed

in the dam body to measure deforma-

tions (see Figure 1). A total of four

vertical inclinometers (INV) anchored

in bedrock (far end considered fixed)

are used to monitor movements closer

to the core as well as in the 3O and

3P rockfills. The INV in the 3P zone

represented on Figure 1 is located at

a section where bedrock elevation is

higher. Two horizontal inclinometers

(INH) and one ShapeAccelArray

(SAA) are also installed to monitor

settlements. The far and near ends of

these three instruments are not consid-

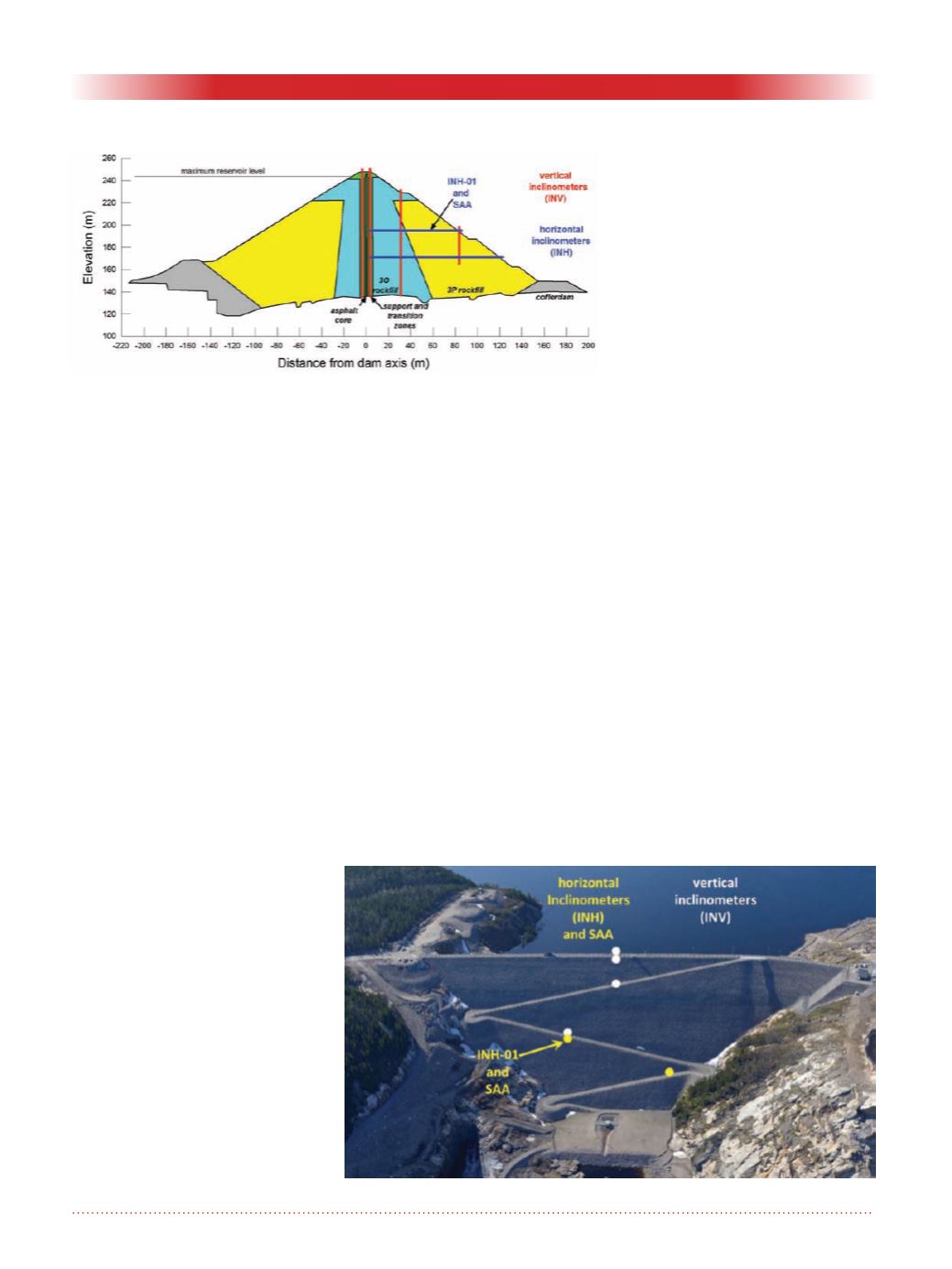

ered fixed. Figure 2 shows the location

of the INV, INH and SAA.

The SAA is installed along INH-01

(see also Figure 1). An access road on

the dam crest and downstream face

allows instrumentation readings.

INH characteristics

The two INH are composed of 1.5

m-long grooved ABS casings installed

horizontally in a trench excavated in

the placed rockfill. Settlement read-

ings are made using an accelerometer

probe which measures tilt at every 0.5

m in the plane of the probe wheels

travelling in the top and bottom

grooves of the casings. The probe is

inserted in the horizontal inclinometer

using a system of return cable and pul-

ley. The return cable is installed within

a separate pipe alongside the incli-

nometer casing. The tilt measurements

from two sets of readings (probe

reversed end-for-end) are converted to

settlements at the office.

INH were installed in other Hydro

Québec projects but have been subject

to operation problems after two to

three years due to ice build-ups inside

the casings as well as pulley and return

cable malfunctions. These problems

had a significant effect on the avail-

ability and the reliability of results.

Long-term settlement monitoring

along a horizontal plane gives valuable

information related to the deformation

of the various types of materials con-

stituting an embankment dam. Defor-

mations need to be measured during

the construction (load increase due to

fill placement), impoundment (load

due to reservoir) and operation (creep)

phases of the dam life cycle. Another

option was thus needed to obtain

reliable settlement measurements. A

SAA was therefore installed in the

Romaine-2 dam to gain confidence in

this relatively new technology.

SAA characteristics

A SAA consists in a series of rigid

segments separated by special joints

which can tolerate the range of settle-

Figure 2. Location of inclinometers and SAA.

Figure 1. Schematic cross section of the Romaine-2 dam and location of

inclinometers and SAA.