28

Geotechnical News • March 2017

WASTE GEOTECHNICS

This tailings has the consistency of chocolate pudding:

a formal comparison of the geotechnical vane shear strength

of food and soft tailings

Gord McKenna, Vanessa Mann, Bereket Fisseha, Nick Beier, Nicolas Olmedo

Introduction

“This tailings pours like chocolate

milk, but when you add flocculant,

it becomes more like blueberry pie

filling.”

We often compare the unusual geo-

technical properties of soft tailings

to common foods. Soft tailings shear

strengths are much lower than most

geotechnical people are accustomed

– indeed many tailings are better

described using fluid mechanics than

soil mechanics. So people describe

the consistency (mainly strength, but

also sensitivity and density) of soft

tailings using informal comparisons to

foods such as chocolate milk, yogurt,

porridge, cottage cheese, and peanut

butter.

Lacking is an accessible reference

that provides a more direct, more

authoritative comparison of tailings

and foods. So with two hours at the

grocery story, two days of hard work

in the University of Alberta laboratory,

and two weeks of crunching the data

and writing it up for a recent oil sands

tailings publication (see McKenna

et al 2016a) we’re pleased to share

the results with a wider geotechnical

audience.

To allow a direct comparison of tail-

ings and food, we measured the peak

and remolded strength of 75 samples

of soft tailings, soft foods, and house-

hold products using the geotechnical

laboratory vane test, specifically the

ASTM D4648 test method for vane

strength of saturated fine-grained soils.

We also performed some other infor-

mal tests on each sample as described

below.

While our comparison of tailings to

foods is meant to be perhaps a bit

lighthearted, it also has point. Many

mines (most notably the oil sands)

have major issues with the technical

and operational challenges of manag-

ing soft tailings – stabilizing or repro-

cessing or the tailings to allow mine

reclamation to produce useful post-

mining landscapes. Soft tailings by

definition have such low strengths and

densities that they cannot be trafficked

by typical earthmoving equipment,

which severely limits reclamation.

The presence of soft tailings, and the

cost to reclaim them, usually comes

as a surprise to mines. That one can

directly compare soft tailings to com-

mon foods highlights the challenge of

converting these soft or fluid tailings

to solid landscapes. Oil sands min-

ing operations in northeastern Alberta

have produced over one billion cubic

metres of soft tailings which are chal-

lenging to stabilize and reclaim to

boreal forest landscapes (CCA 2015)

and the subject of billions of dollars

of research and development and

commercialization (see CTMC 2012).

Many metals mines worldwide have

similar issues, but at smaller scales.

Background

Soil consistency descriptors, avail-

able in most soil mechanics textbooks,

have been used for over a century.

Very soft soils can be extruded

between the fingers when squeezed

(shear strength <12 kPa). Soft soils

can be molded with light finger pres-

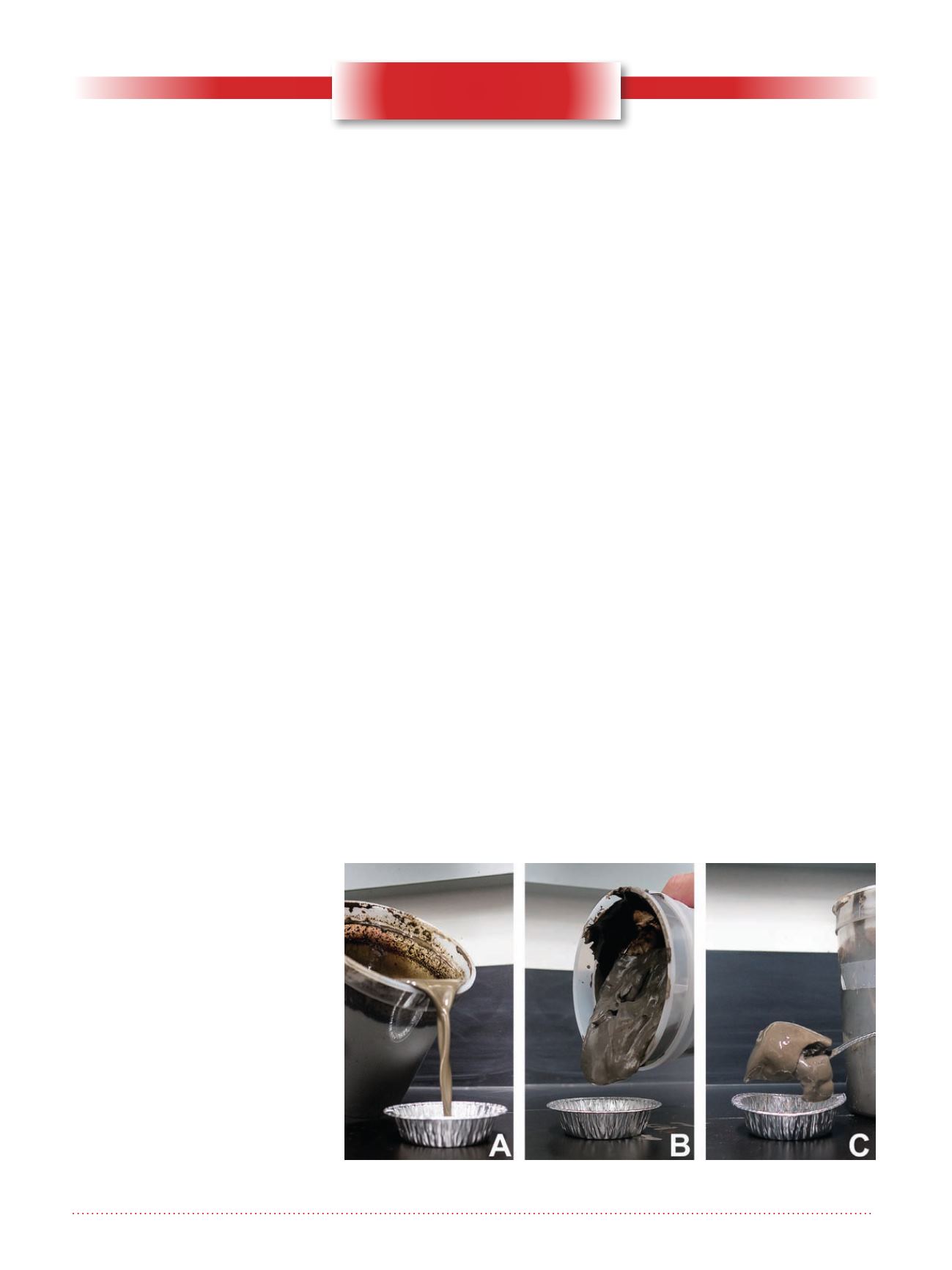

Figure 1. Three oil sands soft tailings. A - fluid fine tailings; B - centrifuged

fluid fine tailings; C - thickened tailings (TT) + fly ash.