Geotechnical News • March 2017

37

GEOTECHNICAL INSTRUMENTATION NEWS

the telescope with as small a chance of

ambiguity as possible. Some examples

of these are: paint marks already on

structures and buildings, flat bolts, ink

marks, nail heads, imperfections in

color or marks on bricks and masonry.

Keep in mind that the points may have

to be read during rainy periods so they

should also be visible when wet.

When the initial readings are taken, it

is important to keep in mind that the

geometry used for the initial readings

has to be repeatable going forward.

Large changes in the geometry can

introduce significant ambiguity into

the readings, causing them to become

suspect. Bad data are worse than no

data. Taking the initial and subsequent

readings from a safe, stable and secure

location is strongly advised. With a

little bit of planning and forethought,

it is possible to take accurate and

precise readings from a pre-planned

location(s).

Accuracy and precision

Accuracy is the truthfulness of the

targets location while precision is the

repeatability of measurements to the

same point each time it is measured.

One of the best ways to guarantee

precise results is to use the same

geometry, instrument and operator for

all of the readings. While this is not

always possible in reality, using the

same geometry as much as possible

is one of the most important steps to

follow. While MRTS instruments can

measure to inaccessible locations, it

can be hard to know what happens to

the laser as it travels to and from the

monitoring point or even if it is hit-

ting the right point. Measuring to the

wrong type of surface, not understand-

ing the properties of the laser and how

it is affected by atmospheric condi-

tions and the impact of those condi-

tions on the measurements all have

varying effects. It is also important

to understand what the instrument is

capable of and under what conditions

it operates at its best.

Measurement on two faces

Using the instrument in both faces

will control any calibration errors in

the instrument and is needed for the

accuracy it provides for MRTS read-

ings. By taking readings on both faces

of the instrument multiple times then

averaging the initial measurements of

the controls and the monitoring points

the measurements can be kept within

a tolerable range as long as the correct

procedures are followed. If large dif-

ferences are noted between readings

on either face of the instrument then a

change in geometry to a more perpen-

dicular location is recommended.

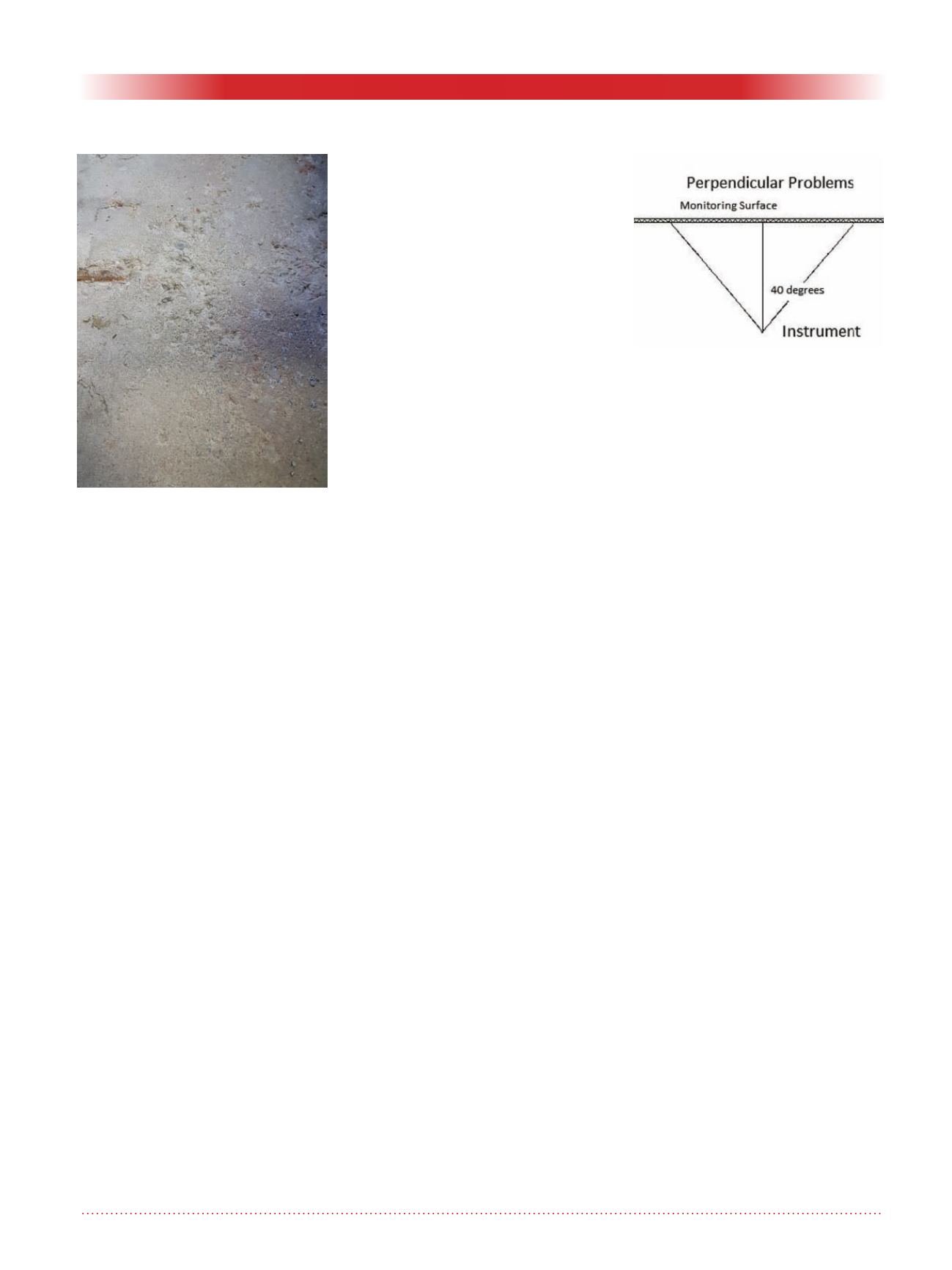

Perpendicularity

By keeping measurement angles

within an 80 degree range as much as

possible, the laser will return an accu-

rate and precise measurement of the

location of the point. A way to think

of this is to stay as perpendicular to as

many monitoring points as is pos-

sible. Any monitoring or control point

should be within 40 degrees of the

perpendicular for the most consistent

and accurate readings. Figure 2 shows

a graphical representation of perpen-

dicularity.

Precise mode versus reflector-

less mode experiment

The same geometry is used for each

set of readings along with the same

operator and instrument. All of the

points being monitored were re-

initialised in both precise and MRTS

mode with the MRTS points also

being read on two faces. Precise Mode

is the method used when reflective

targets are available; however, the

laser is subject to deflection when

objects are within close proximity

of its line of flight. (Approx. 50mm)

Reflectorless mode uses the changes in

the phase shift as one way to calculate

positons while also using the time of

flight method for calculations. During

the monitoring, most of the readings

were taken through temporary fences

which can cause problems in precise

mode, as noticeable deflections occur

when the precise laser travels too

closely to any objects along the line of

sight. Figure 3 shows a colour coded

graph with reds being MRTS mea-

surements and greens being precise

measurements.

Conclusions

When there is a good geometry,

when readings are taken with a high

standard of care and you have the right

instrument, it is a good alternative to

use MRTS monitoring, especially if

traditional methods are difficult or

impossible.

A good geometry is a system of con-

trols installed on at least two axes with

at least five targets spread as evenly as

possible, while staying as perpendicu-

lar to as many points as possible and

not exceeding forty degrees from the

perpendicular when taking measure-

ments.

Figure 2. Shows a graphical repre-

sentation of perpendicularity.

Figure 1. Shows a poor surface for

reflectorless monitoring.