Geotechnical News • December 2017

31

THE GROUT LINE

• greater insurance for long term

blockage

• act as a stepping stone for more

challenging treatments

The majority of the trials with 4.5

ratio sodium silicate has been as a

compliment to a cement squeeze.

The 4.5 ratio material was diluted

1:1 with water for a total volume of

500 to 1000 litres. This material was

squeezed using a pressure pump-

ing unit. (see figure 3). Typically,

the setting process would begin as

the squeezed silicate was exposed

to calcium rich environment of the

microchannels. As injection pressure

increased a small volume of fresh

water would be pumped behind the sil-

icate to act as a spacer for the cement.

Field trials showed a high first-time

success rate using the 4.5 ratio but

more trials would be necessary to

determine if success rate was statisti-

cally higher vs. conventional silicate.

The 4.5 ratio sodium silicate has also

been used as a standalone product to

block gas migrating inside and outside

of the casing. It should be noted that

successful blocking of gas or water

is not just about having an effective

sealant, success is dependent on good

diagnostics to pin point the source(s)

of gas and their pathways. Once com-

munication is established with gas

pathways then proper placement of

the treatment chemical is critical to

success. Trials have been equally split

between using the high ratio mate-

rial by itself or with a setting agent.

Placements of the silicate have been

done with a pressure pumping unit or

with chemical injection pumps (see

figures 3). The advantage of chemical

injection pumps is it allows for low

pump rates over long period times.

The other advantage is it is a low cost

pumping technique. For well abandon-

ment, success requires that venting

gas be reduced to zero. Based on the

limited number of trials the success

rate at achieving total blockage on the

first squeeze is ~66%. In cases where

the volume of venting was reduced

but not eliminated it is felt there were

secondary sources of gas and not all

pathways were available for entry.

Conclusions

The experimental study at GRC pro-

vided a good starting point to assess

the performance of cementation of

clean quartz sand by 4.5 ratio silicate

vs. conventional sodium silicate. The

setting agents used in the study were

citric acid and triacetin. The next

phase of study will look at longer gela

Table 3. Permeability of pure sand vs. consolidated sand with

4.5 ratio and citric acid

Sample

Curing time

Permeability

Control, quartz

sand

N/A

2.30x10¯

⁴

m/s

50% S45-Citric

7 days

2.73x10¯

8

m/s

50% S45-Citric

14 days

7.55x10¯

8

m/s

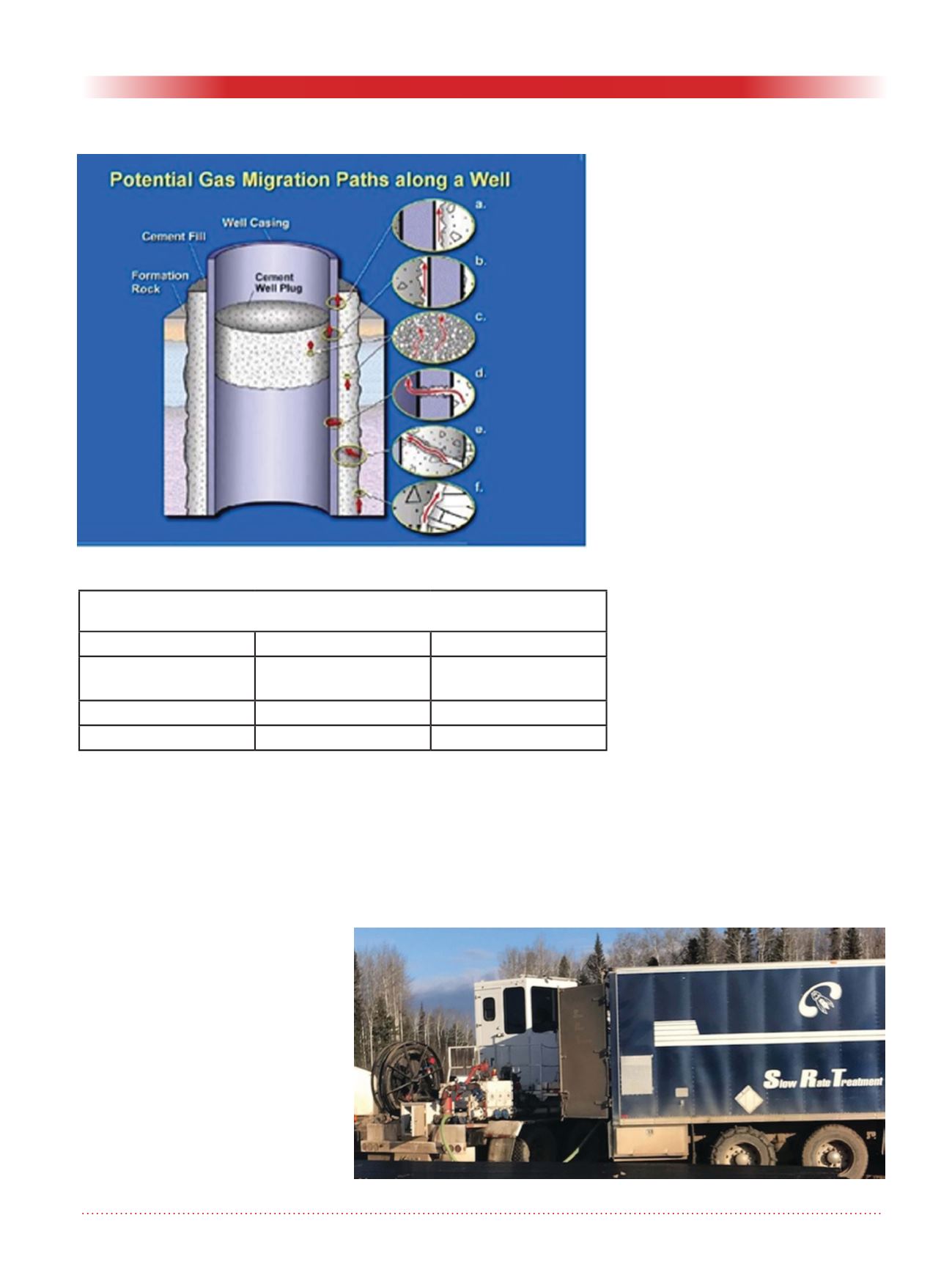

Figure 2: gas pathways in cement.

Figure 3: Silicate squeeze with cement.