Basic HTML Version

34

Geotechnical News • September 2014

www.geotechnicalnews.com

THE GROUT LINE

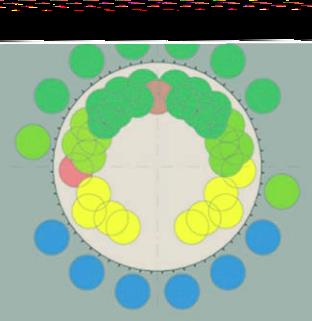

stability of the rock masses ahead of

and around the TBM. Drilling can

be carried out through the cutterhead

or the shield with a pattern of holes

(14 peripheral through the shield;

20 through the cutterhead) char-

acterized by different inclinations (0°,

3.5° and 7°), as illustrated in Figure 3.

Face interventions for maintenance are

planned to occur, most of the time, in

atmospheric conditions. However, in

the event maintenance will be required

during the closed mode operation, the

TBM is equipped and the personnel

are trained for hyperbaric interven-

tions.

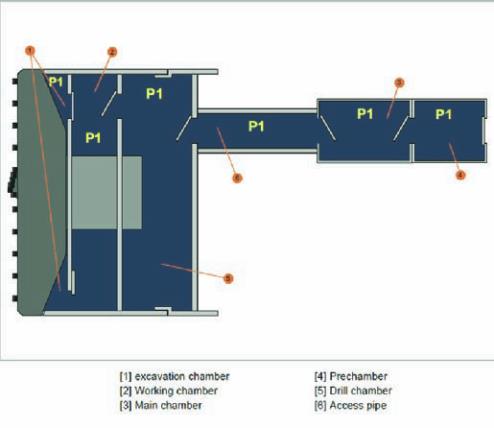

This means that the pressure in the

excavation chamber and in the work-

ing chamber will be the same as the

face pressure.

In order to reach the excavation

chamber and perform maintenance

operations under pressure, the TBM

is equipped with a series of hyper-

baric chambers and access pipe that

connects to the excavation chamber,

which will be pressurized to the same

applied face pressure (Figure 4).

The hyperbaric system also includes

a rail transported,

portable recom-

pression chamber

(Shuttle) that

will be located in

the tunnel dur-

ing hyperbaric

activities and has

the capability

of connecting,

under treat-

ment pressure,

to the Special

Decompression

Chamber (medi-

cal lock) and

also to the TBM

manlock (pre-

chamber).

Mining Activities

The tunnel boring machine was

launched on December 27, 2011.

Based on the expected geological

conditions of the Saddle Island Lower

Plate, the plan was to mine the first

200 m of TBM tunnel in closed mode

with face support pressure less than

7 bar. For logistic reasons and due to

space limitations the conveyor belt

system which was installed after the

first 250 m in the starter tunnel; the

TBM would then operate in open

mode.

After 140 m of excavation at ring

N. 77, the air bubble pressure was

lowered and maintenance was carried

out at atmospheric conditions. At that

point, a sub-vertical fault, entering the

tunnel section from left to right, was

detected and mining resumed with

pressure exceeding 12 bar to compen-

sate the hydraulic head and guarantee

stability at the face. The TBM pro-

gressed very well into the detachment

fault and the slurry pressure in the

excavation chamber was raised to 13

bar in accordance with the groundwa-

ter head and the low cohesive material

at the face.

On July 2, 2012, at approximately 280

m of excavation along the first curve

of the alignment, the TBM penetra-

tion values became lower and lower,

until the machine stopped advancing

at push 158.

Several attempts to free the machine

were unsuccessful. The decision was

made to lower the face pressure to 0

bar to inspect the cutterhead.

In order to access the working

chamber under atmospheric pres-

sure, it is important to estimate in

Figure 2a: Open Mode Configuration.

Figure 2b: Closed Mode Configuration.

Figure 3: Drilling pattern through

the shield (outer holes) and the

cutterhead (inner holes).

Figure 4: All the environments are pressurized at the

same pressure as the face.