Geotechnical News • June 2015

31

THE GROUT LINE

whether the crack is moving or dor-

mant. A grout that remains somewhat

flexible should be used in cracks that

are leaking or moving, whereas a high

bond material such as epoxy, is ideal

where structural bonding is the objec-

tive. Where controlling seepage is the

objective, chemical solution grout, ei-

ther based on acrylic or urethane tech-

nology is typically used. The material

selection depends largely on the nature

of the leakage. Acrylic type grouts

generally penetrate better and are thus

used on fine cracks and seeps, whereas

urethane formulations tend to perform

better on larger and more active leaks.

There are however many different for-

mulations of both generic types, which

provide different performance charac-

teristics.

Grouting in masonry

Voids in masonry, especially in very

old structures, can be continuous and

massive, Figure 10. Exceptional care

must be taken when injecting grout, in

that large internal forces can be devel-

oped as a result of the ever enlarging

pool of grout, and unwanted travel and

leakage can also occur. I once investi-

gated a project where grout injected on

the third floor had run all the way to the

base of the wall into a basement area.

Leakage is also common through sur-

face defects, which can make the oper-

ation quite messy, Figure 11, and result

in a marred surface upon completion.

Strength of the mortar used in masonry

can vary greatly, depending primarily

upon age. Prior to about 1940, very low

strength lime mortars were common

whereas the mortar of modern struc-

tures possesses concrete-like strengths.

Where cementitious grouts are used,

they should match the properties of the

original mortar as closely as practica-

ble. Further, one must take care, to not

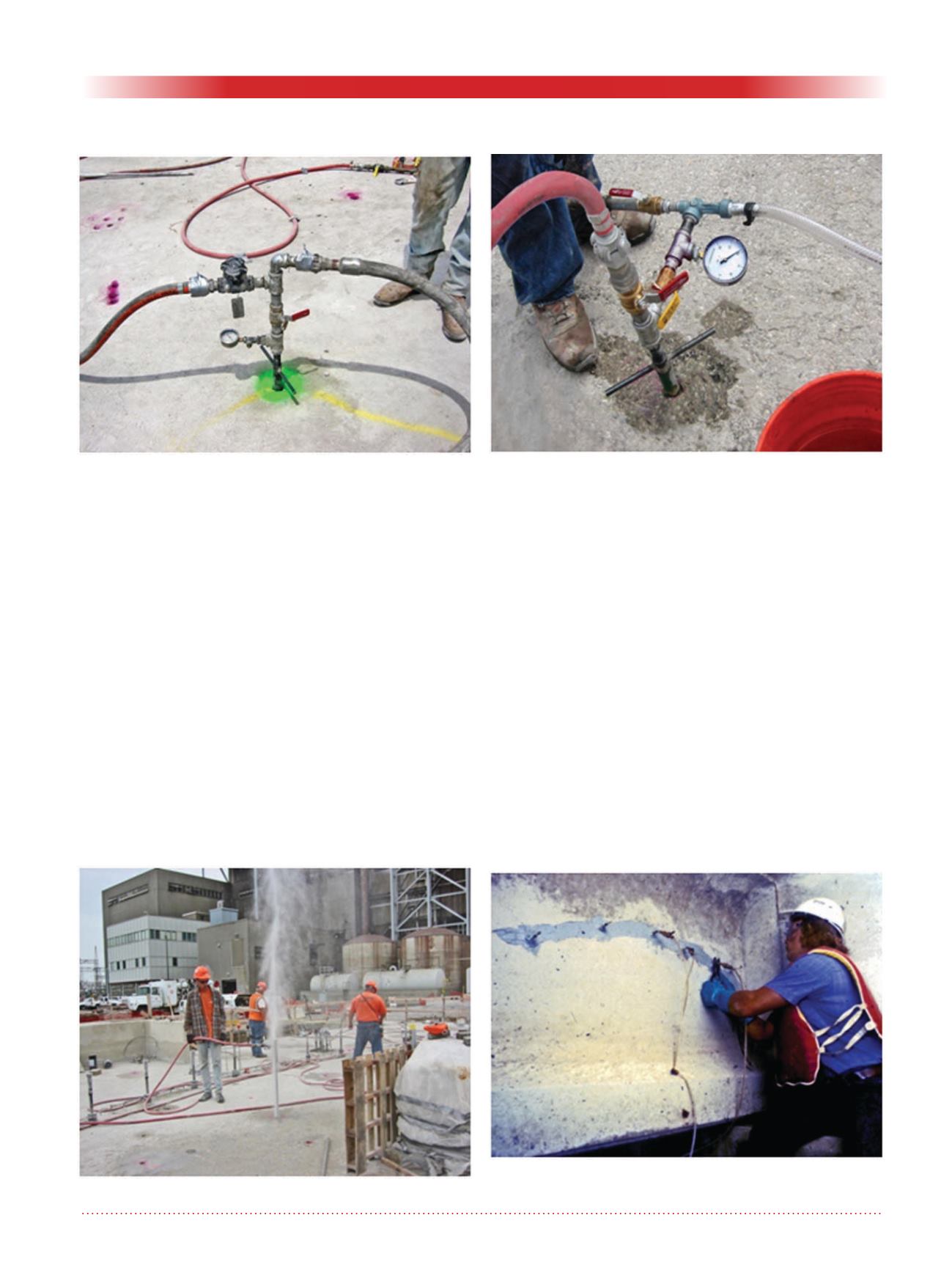

Figure 7. Blowing hole free of water prior to injection.

Figure 8. Typical epoxy injection from surface. Cracks are

pre-sealed and operation can be quite neat.

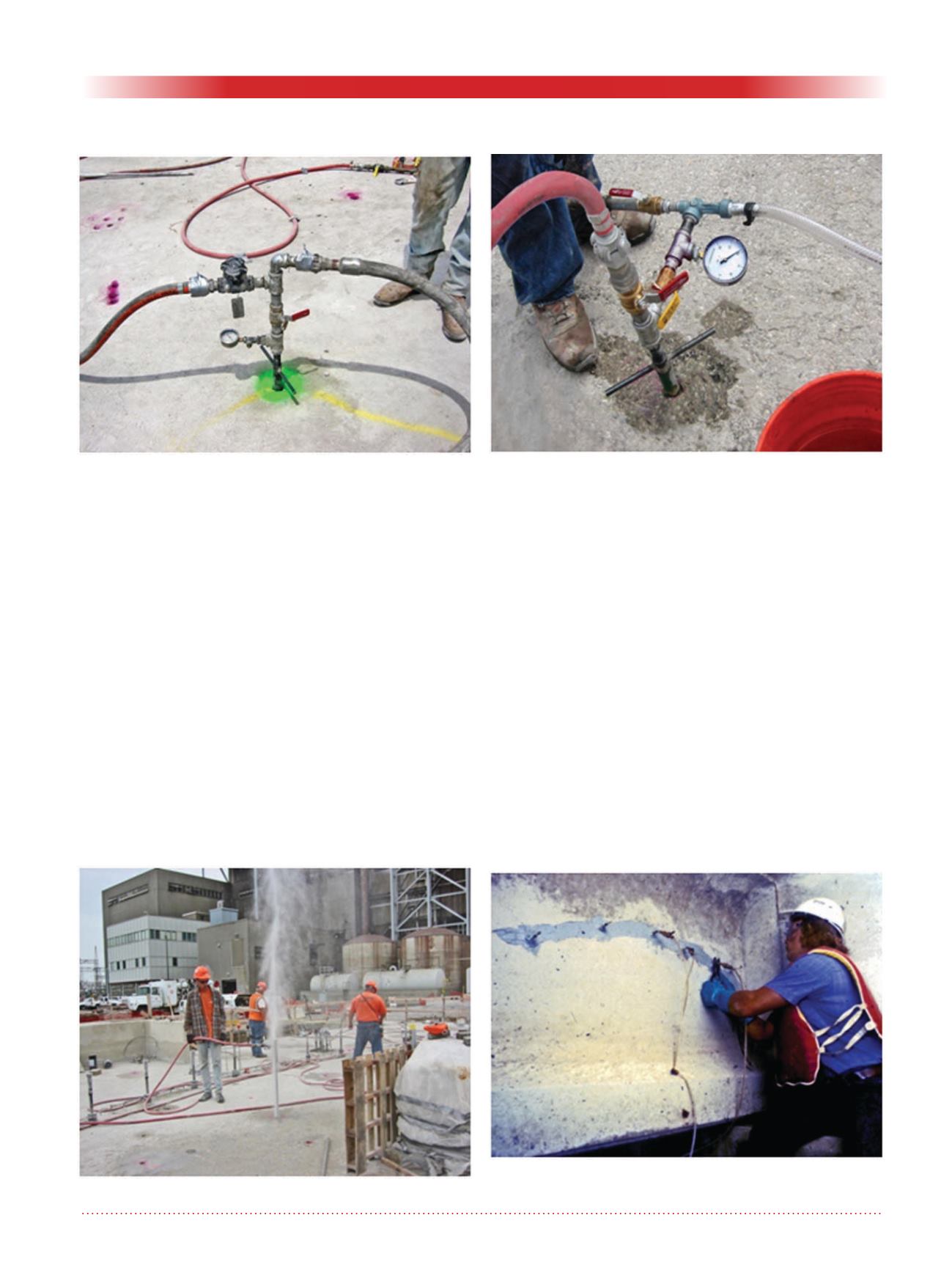

Figure 5. Typical grouting header for circulating injection

system. Supply hose on right, return on left. Valve above

gauge controls injection rate.

Figure 6. Vacuum grouting header. Valved hose top left

is compressed air entering venturi ejector, white hose

on right carries away spent air. Upon sufficient vacuum,

valves are turned from vacuum to grout.