36

Geotechnical News •June 2015

GEOSYNTHETICS

Hydraulic conductivity of the

geotextile

Methods used to determine the per-

mittivity (cross-plane permeability)

of a geotextile involve variations on

laboratory permeameter testing, the

two most common of which are a

‘constant-head’ method and a ‘falling-

head’ method (see for example, ASTM

D4491 and ISO 11058). The geotextile

specimen is not subject to any normal

load in these index tests, and therefore

is tested in an uncompressed state.

Where appropriate, provision exists

to perform the test under a specified

compressive stress (see for example,

ASTM D5493 and ISO 10776).

Experience suggests the compressive

stress yields no significant change to

the permittivity of a woven geotextile

or a nonwoven heat-bonded geotextile,

but causes a reduction in permittivity

in nonwoven needle-punched geotex-

tiles. Using image analysis techniques,

Palmeira and Gardoni (2000) attri-

bute the reduction in flow capacity to

an increase in contacts between the

needle-punched fibres, and therefore a

greater constriction of pore channels

across the plane of the geotextile.

Multiplying the permittivity by the

nominal thickness of the geotextile

yields a nominal value of permeability

or hydraulic conductivity. However,

given the range in thickness of differ-

ent types of geotextile, it is generally

recognized that reporting a value of

permittivity avoids the potential for

any misleading comparison of perme-

ability between different products. As

for granular filters, the permittivity

values of geotextiles vary over several

orders of magnitude.

Geotextile tensile strength

Woven and nonwoven geotextiles

exhibit a very different characteristic

response to loading which, again, is a

direct consequence of the manufactur-

ing process. Woven geotextiles exhibit

a significantly greater stiffness upon

loading, a response that arises from

the preferential alignment of polymer

strands during the weaving process. In

contrast, nonwoven geotextiles have a

random layout of polymer strands that

must progressively deform in order

to align themselves in the direction

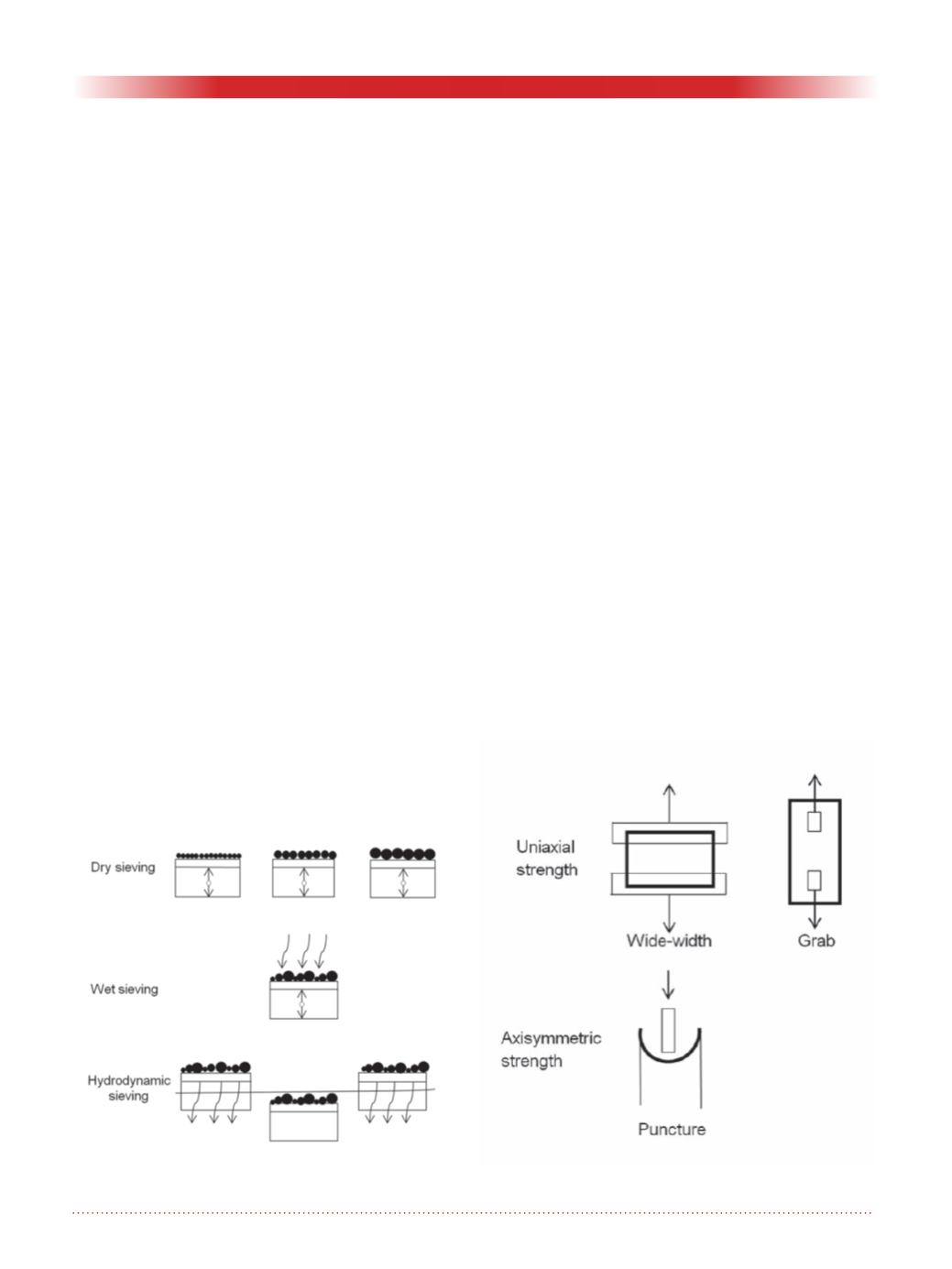

of imposed loading. Methods used to

determine the strength of a geotex-

tile involve loading it to failure as a

result of tensile rupture of the polymer

strands (see Fig. 3):

the two most com-

mon methods are

uniaxial-tension testing of a rectangu-

lar specimen (using either a full ‘wide-

width’ clamp, else a partial ‘grab’

clamp) and axisymmetric-tension

testing of a circular specimen (using a

rod to puncture).

In the ‘wide-width’ style of test, a rect-

angular specimen is clamped across

its entire width and the load-extension

response then measured over a speci-

fied gauge length, for loading imposed

at a constant rate of axial displace-

ment (see for example, ASTM D4595

and ISO10319). In a variation to this

method, only the central portion of a

rectangular specimen is clamped over

a specified gauge length in the ‘grab’

style of test (see for example, ASTM

4632). Static puncture resistance is

measured by advancing a probe of

specified diameter into a specimen that

is clamped between circular rings, at a

constant rate of displacement, in order

to determine the maximum resistance

(see for example, ASTM D6241 and

ISO 12236). In a variation to this

concept, a cone is dropped through a

specified distance onto a circular test

specimen, in order to measure the

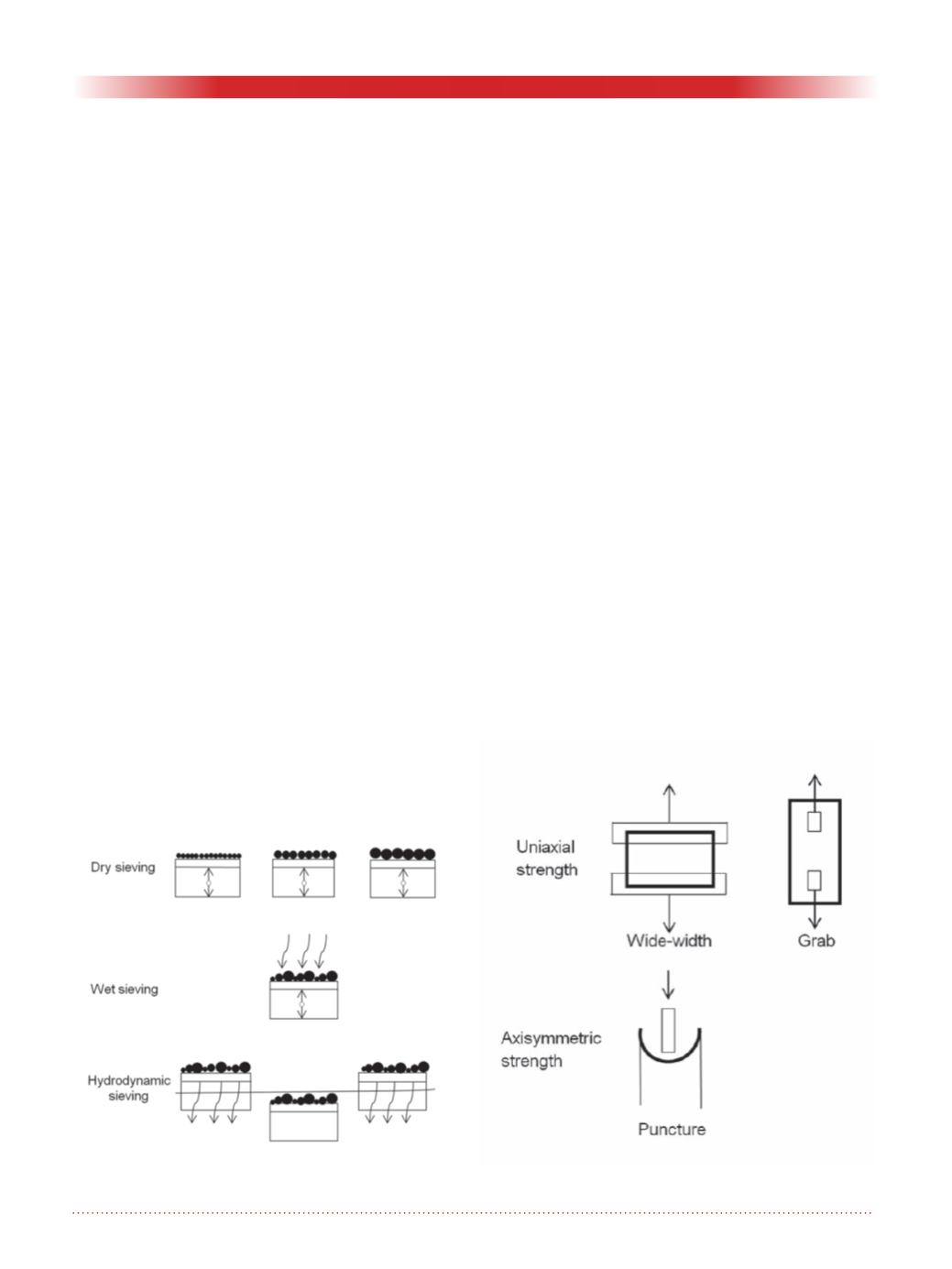

Figure 2. Standard test methods for pore size opening.

Figure 3. Standard test methods for strength.