Geotechnical News • June 2015

35

GEOSYNTHETICS

design, the assessment of a candidate

geotextile for a proposed filtration

application must address a series of

material properties. A value for each

material property is typically obtained

from laboratory index tests performed

in accordance with the appropriate

national or international standard test

method. When specifying a geotextile

for a filter application, our primary

interest lies in determining an index

value for the pore size opening, the

permittivity and the strength of the

fabric (see Fig. 1). Consider now the

measurement and reporting of each of

these index properties.

Pore size opening of the

geotextile

The manufacturing process exerts

a significant influence on the pore

structure of a geotextile. A woven

geotextile exhibits a relatively uniform

pore structure that is characterized

by openings of nearly constant size

and little spatial variability across the

surface of the roll. The weave pattern

may differ between products, as may

the size of the polymer strands used

to provide the materials of the warp

and the weft, both of which govern the

size of the resulting openings between

the strands. In contrast, a nonwoven

geotextile exhibits a relatively wide

range of opening sizes which vary spa-

tially across the surface of the roll. As

a result, the pore-size distribution is

strongly influenced by factors includ-

ing the type and density of strands

and, in the case of a needle-punched

product, the needle-shape, punch

density and direction or, in the case of

a heat-bonded product, the nature of

the contact surface and line-speed of

the heated rollers (Bhatia and Smith,

1996). Accordingly, the two main

types of geotextile, namely woven and

nonwoven, exhibit a significantly dif-

ferent pore structure.

Index test methods used to determine

the pore size opening of a geotex-

tile involve (i) variations on reverse

sieving of grains through the pores of

the fabric (by means of a dry siev-

ing, a wet sieving or a hydrodynamic

sieving method, as illustrated in Fig.

2), (ii) the injection or removal of a

fluid from the pores of the fabric (by

mercury intrusion porosimetry, or a

bubble point method, respectively)

and (iii) direct image analysis of the

pore space. Current design practice is

based on methods of reverse-sieving,

for which manufacturers report values

in their technical literature.

Reverse-sieving methods are suitable

for determining the largest pore size

openings, which are believed to exert

the greatest influence on base soil

retention in filtration applications. In

dry sieving (see for example, ASTM

D4751), different size fractions of

glass beads (from small to large, in

ascending sequence of size fraction)

are sieved through the geotextile

by means of a shaking action. The

surface of the fabric is pre-treated

with an anti-static spray to minimize

the influence of attraction resulting

from static electricity. In wet siev-

ing (see for example, ISO 12956),

a graded mixture of glass beads is

sieved by shaking in combination with

a continuous spray of water, following

pre-treatment of the fabric by a wet-

ting agent. In hydrodynamic sieving

(see for example, CAN CGSB 148.1

No.10), a graded mixture of glass

beads is sieved by repeated immersion

of the geotextile in water and hence

alternating flow conditions, without

any shaking action.

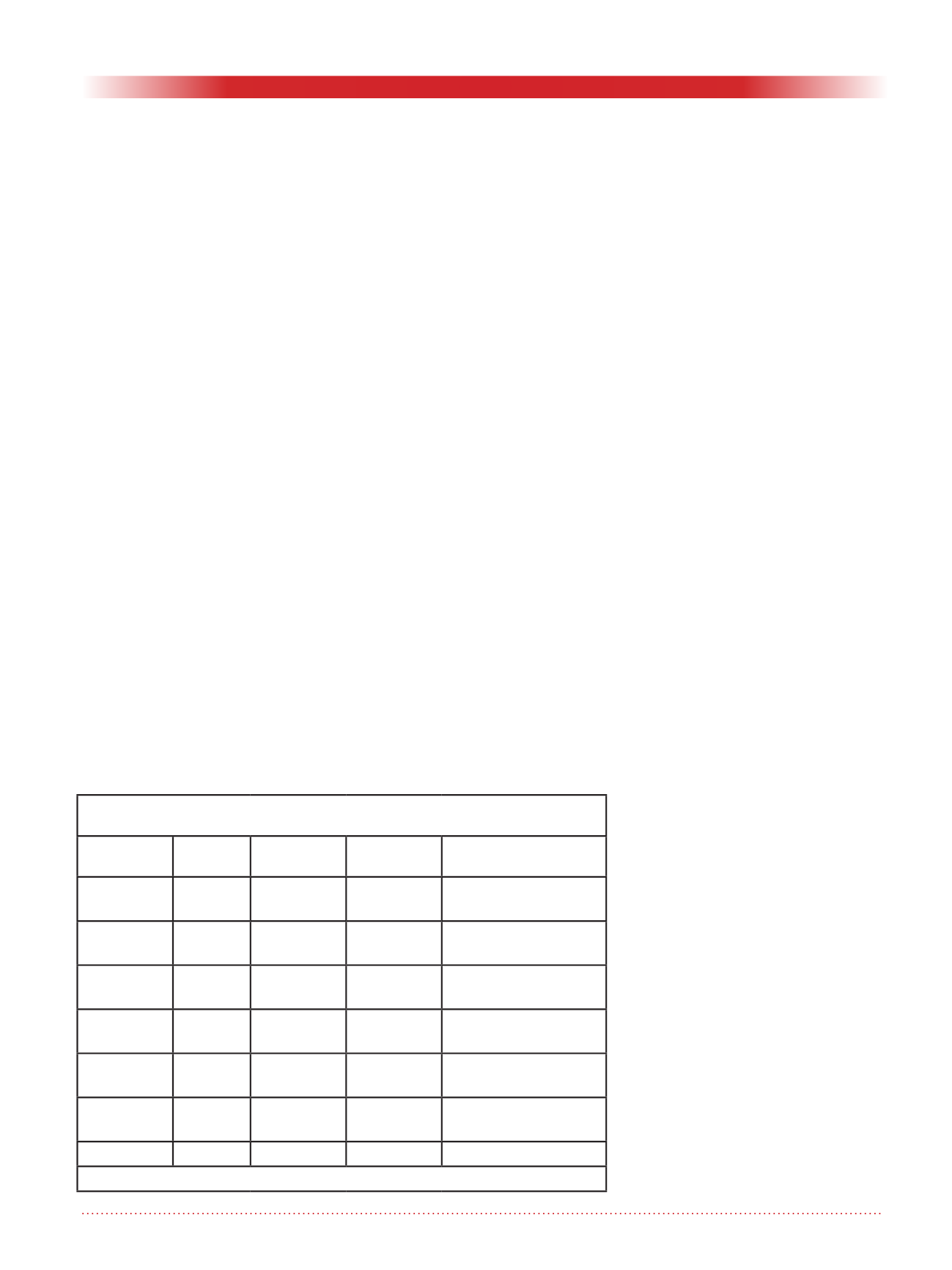

A common aspect of all three stan-

dard test methods (see Fig. 2), is that

a gradation analysis of beads passing

through the fabric during a standard-

ized duration of shaking or number

of immersion cycles is used to infer

the size of the largest pore openings

in the geotextile. The three methods

yield similar but not identical values

of opening size (see Table 1). Gener-

ally, the dry sieving method yields

a relatively larger value of pore size

than that obtained from either wet

sieving or hydrodynamic sieving (see

for example, Faure et al., 1986; Van

der Sluys and Dierickx, 1990; Bhatia

et al., 1996). Accordingly, when using

design criteria for soil retention that

relate a characteristic opening size of

the geotextile to a characteristic grain

size of the base soil, it is important to

recognize not only the empirical origin

of the design criterion but also the cor-

relation to a particular laboratory test

method to determine the opening size

of the geotextile.

Tabel 1. Variation of pore size opening (μm) with sieving technique

(extracted from Van der Sluys and Dierickx, 1990)

Geotextile

O

n

(μm)

Dry

sieving

Wet

sieving

Hydrodynamic

sieving

W3

O

90

O

98

278

348

301

387

282

374

W4

O

90

O

98

354

416

307

358

303

360

W6

O

90

O

98

294

339

259

295

225

289

W7

O

90

O

98

253

260

172

210

194

224

NW1

O

90

O

98

179

202

143

195

133

181

NW3

O

90

O

98

204

236

145

191

150

202

NW4

O

90

210

189

150

Note: Woven (W) geotextile: Nonwoven (NW) geotextile