Geotechnical News • September 2017

37

GROUNDWATER

Sainte-Marthe was used. The mixing

was conducted within a barrel which

had an effective capacity of around

150 liters. The ingredients were

measured in the field with a portable

balance. The water was first poured

into the barrel. Then, the cement was

slowly added to the water and mixed

thoroughly. Next, bentonite powder

was gradually added into the barrel to

avoid forming clumps.

Grout samples were poured in

cylindrical plastic moulds after grout

mixing. The grout samples were left

in the field to set for a week, and then

transferred to a humid room for further

curing. During setting, grout G3 was

not stable and experienced significant

segregation. This segregation was also

observed in borehole F3, where grout

G3 was used for piezometer sealing.

The volume of grout G3 decreased by

25-30 % in both the mould and bore-

hole F3 after the setting period. The

low grout viscosity was most probably

responsible for the segregation.

The 28-day permeability and com-

pressibility tests were conducted on

the hardened 4-inch grout specimens

following standards ASTM D5084 and

ASTM D4767 (Table 1). The average

hydraulic conductivity values of grout

G1 and G3 were respectively 6.1×10

-9

and 1.2×10

-6

m/s (Table 1). Because

the clay hydraulic conductivity is

1.08×10

-9

m/s, the permeability ratios

are around 1100 and 6 for grouts G3

and G1 respectively and the surround-

ing clay.

Pore pressure response of fully

grouted VWPs

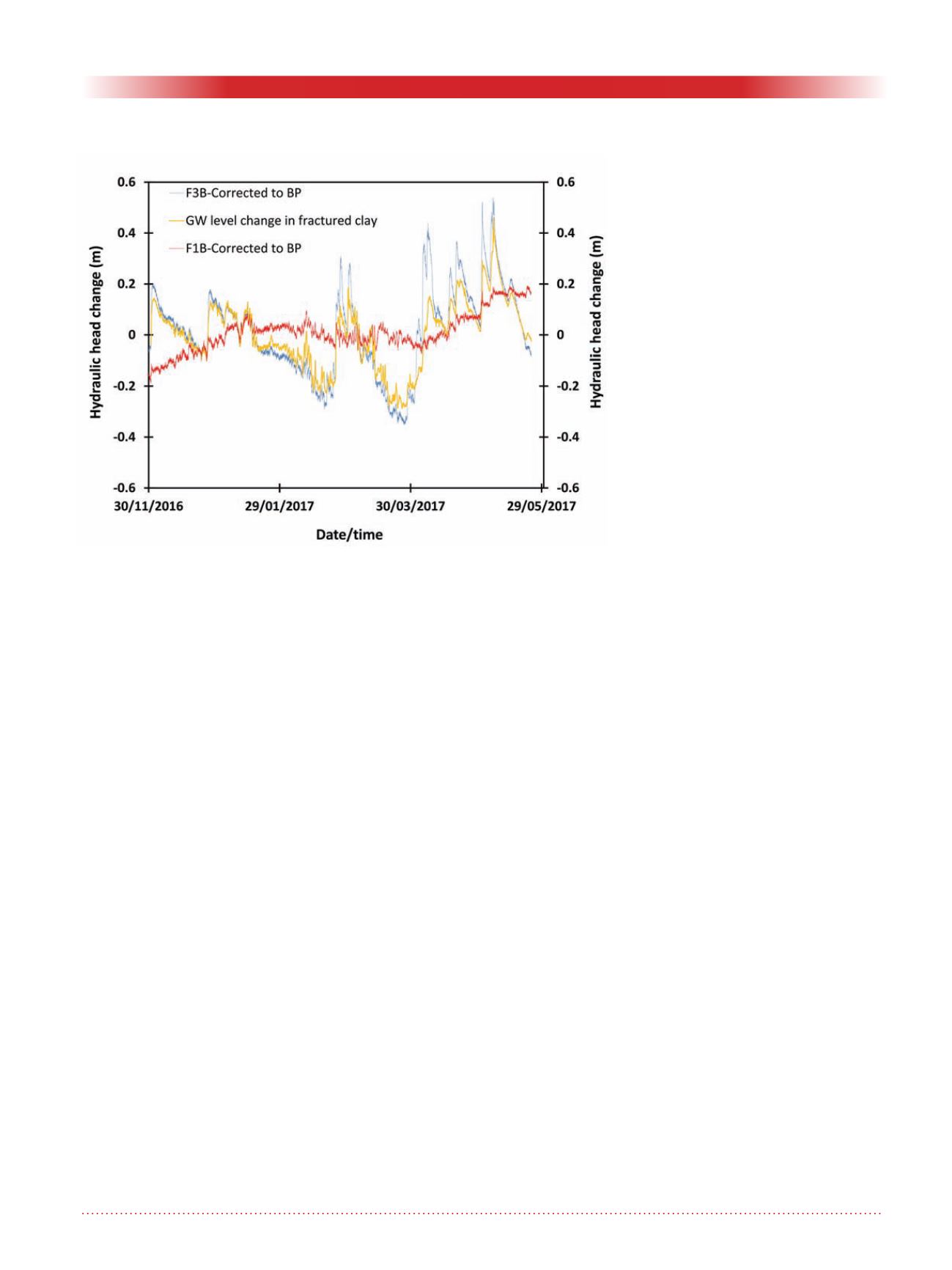

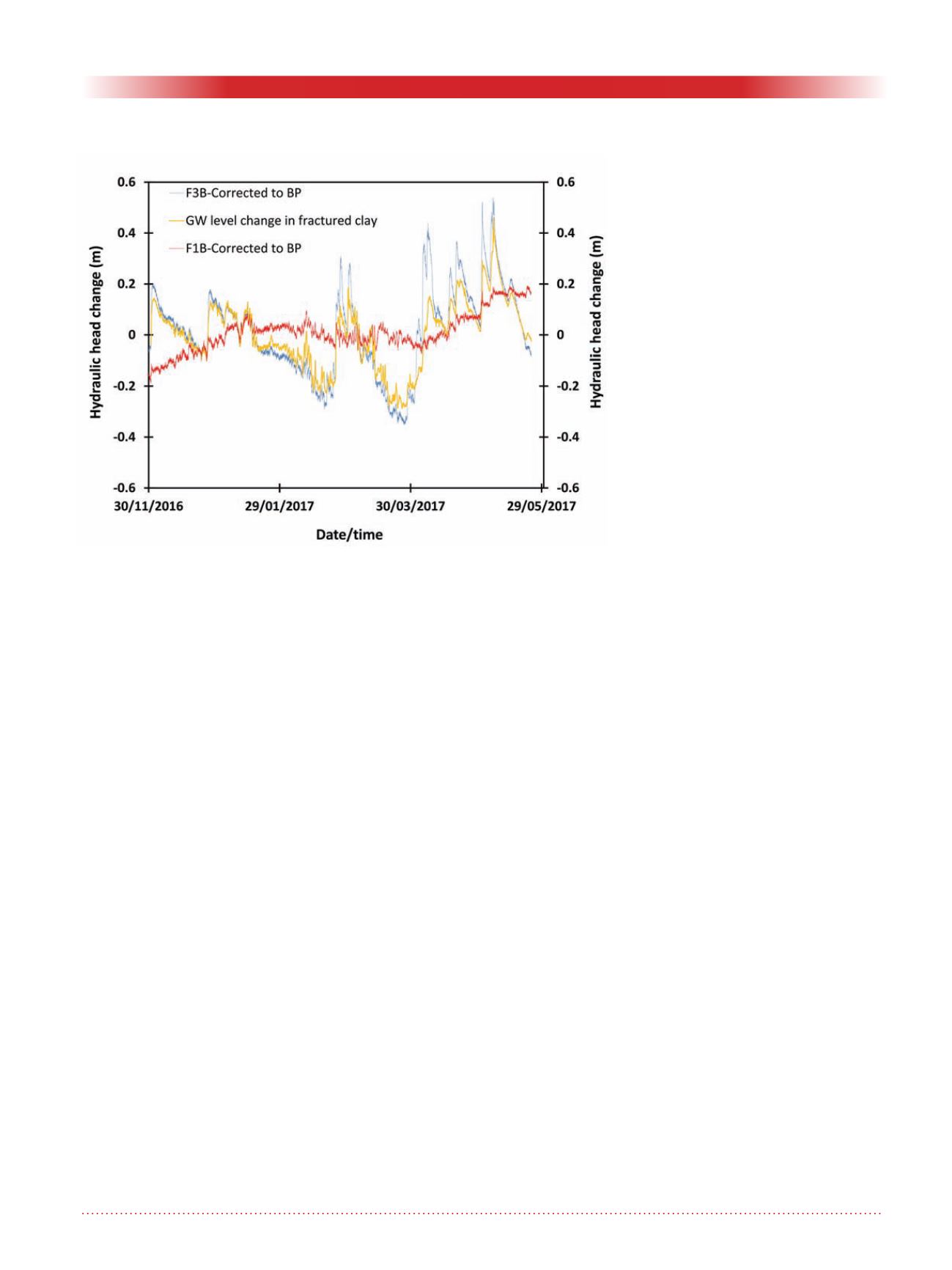

Figure 3 presents the change in

groundwater level in the fractured

clay and hydraulic head in the lower

portion of the intact clay. All data

were plotted around their respective

mean values observed during the

study period (November 2016 - June

2017). The observed pore pressure

and groundwater level data were cor-

rected for barometric pressure (BP)

effects using the multiple regression

technique as described in Marefat et

al. (2015). As shown in Fig. 3, the

groundwater level in the fractured

clay responded to several precipitation

and snow melting events. Secondly,

in the lower portion of the clay layer,

the pore pressure response of fully

grouted piezometers F1B and F3B

differed significantly. The response

of F3B, backfilled with high perme-

ability grout (K=1.2×10

-6

m/s, a

permeability ratio of 1100), mimics

the groundwater level change in the

upper fractured clay, which is acting

as an aquifer. This is a consequence

of the hydraulic connection between

the fully grouted piezometer and the

upper aquifer due to the relatively high

hydraulic conductivity of grout G3.

On the other hand, piezometer F1B

backfilled with the low permeability

grout (K=6.1×10

-9

m/s, a permeability

ratio of 6) registered a smooth pore

pressure response as expected for an

intact clay layer.

Discussion

The viscosity of the grout mix and

hydraulic conductivity of the hardened

grout are very important parameters

to register representative pore pres-

sure with fully-grouted piezometers.

There is no agreement on the accept-

able permeability contrast between the

soil and the grout. Furthermore, the

current method to check the proper

grout viscosity is qualitative. Our field

observations have shown that using

a grout with a hydraulic conductivity

ratio of less than 10 resulted in pore

pressure response that was smooth

and dampened as expected for intact

clay. However, a grout with a perme-

ability ratio of around 1100 resulted in

a totally differed response. A hydraulic

conductivity ratio of 1100 created

a hydraulic connection between the

fully grouted piezometer in clay and

the upper aquifer. As mentioned in

Mikkelsen (2002) the current recipe

for the installation of fully grouted

piezometers in soft soil is only an ini-

tial guide to prepare a suitable grout.

This study showed that following the

proposed recipes by Mikkelsen (2002)

without considering grout consistency

or viscosity can result in an unstable

grout. According to Mikkelsen (2002)

the grout mix should be like “thick

cream or pancake batter” to be physi-

cally stable and pumpable. However,

Figure 3. Groundwater level changes in the fractured clay and pore pressures

registered in the lower portion of borehole F3 (high-permeability grout) and

borehole F1 (low-permeability grout).