36

Geotechnical News • September 2017

GROUNDWATER

Borehole drilling, grout recipes

and piezometer installation

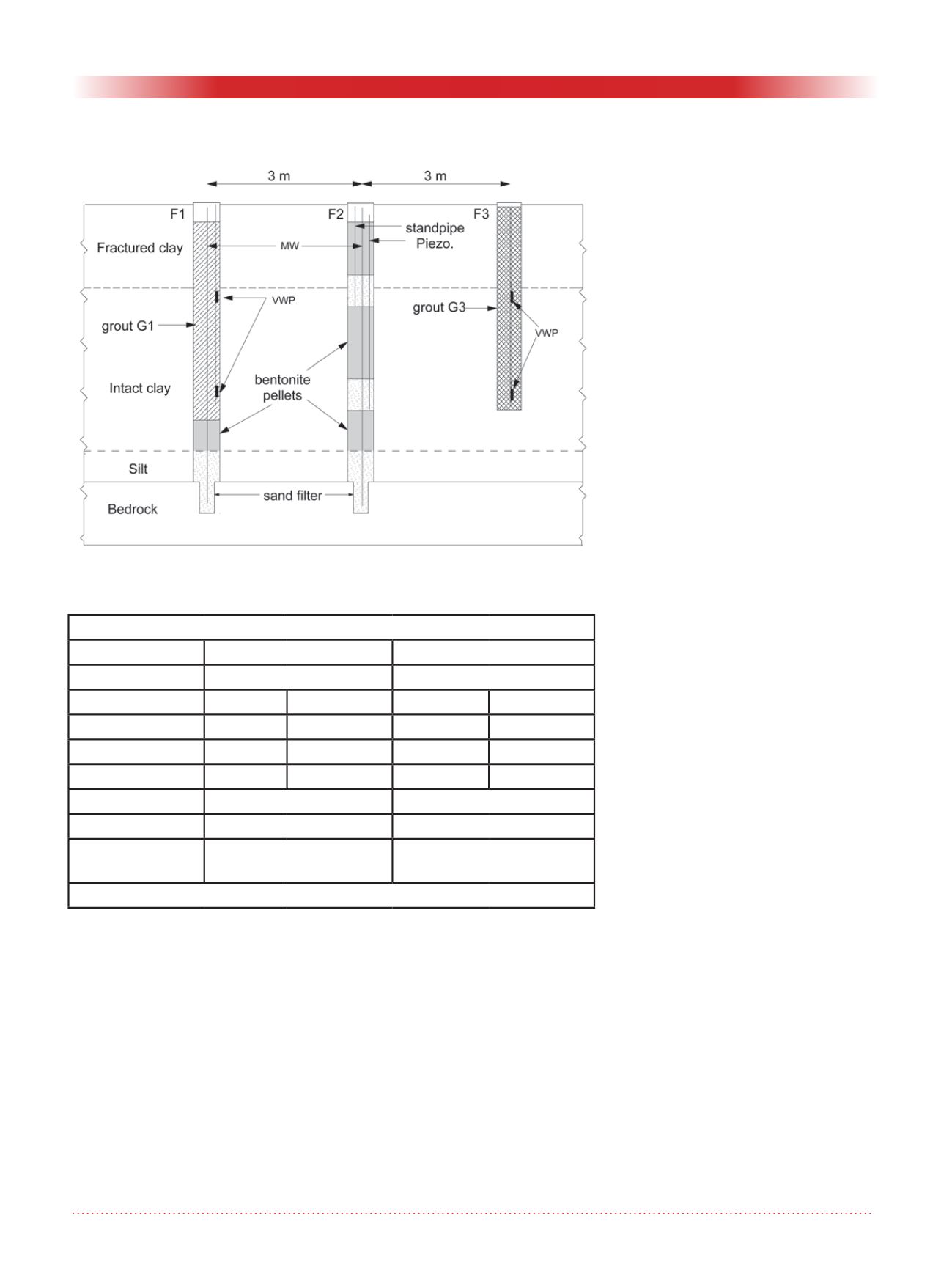

Boreholes F1, F2 and F3 were drilled

in October 2016 using wash boring,

with a flush-joint casing of diameter

114 mm. The boreholes are spaced

3 m apart. Borehole F3 was drilled

to the lower third of the clay layer to

a depth of 12.5 m from the ground

surface while boreholes F1 and F2

were drilled into the bedrock down to

a depth of 22 m. The clay layer was

sampled using thin-walled tube sam-

plers (3”) at 1.5-m intervals. Figure 2

shows a cross-section of the boreholes

F1, F2 and F3. Two monitoring wells

(MWs) were installed in F1 and F2.

The MWs’ intake zones were located

at the interface with the fractured

bedrock and silty layers. In each bore-

hole, two multilevel piezometers were

installed approximately at the lower

and upper third of the clay layer. The

multilevel piezometers monitor pore

pressure fluctuations within the clay

layer. Boreholes F1 and F3 include

two vibrating wire piezometers

(VWPs), which were fully grouted at

depths of 6.1 and 12.2 m below the

ground surface. Borehole F2 contains

two standpipe piezometers with a sand

filter around their screen. The center

of the intake zones for the standpipe

piezometers was located at the same

depth as the VWPs (Fig. 2).

The vibrating wire piezometers were

calibrated before the installation.

The piezometers were kept under

water until their installation. Once

the boreholes were drilled, the VWPs

were attached to a ¾-inch grout pipe,

which was lowered into the borehole

to the appropriate depth. After having

positioned the piezometer assembly

in the borehole, grouting was started

from the bottom up.

Two grout recipes were used to seal

the VWPs in boreholes F1 and F3.

The grout for F3, later referred to as

G3, corresponds to the grout recipe

suggested by Mikkelsen (2002). The

weight proportions were 6.5 parts

water: 1 part cement: 0.4 parts ben-

tonite. Mikkelsen (2002) suggested

adding more bentonite to this recipe

for viscosity adjustments. Bentonite

was not added in this case to obtain

the properties for the exact recipe. A

new grout recipe (G1) was designed

for borehole F1 with a higher benton-

ite content. The weight proportions

for the new recipe were 5 parts water:

1 part cement: 1.2 parts bentonite.

The higher amount of bentonite made

the grout more viscous. A viscous

grout does not easily flow into nar-

row spaces, for example between

the piezometer cord and grout pipe.

Therefore, a liquid and chloride free

superplasticizer (SP) was added in rec-

ipe G1 in order to increase the grout

flowability. The concentration of SP

was about 2.0% of the solid weight.

The laboratory values for the Marsh

funnel viscosity were 55 s and 29 s

respectively for grouts G1 and G3.

All materials used in this work were

produced in Canada. The cement was

general use (GU) cement, and the

sodium bentonite (Opta Minerals) was

a powder. Tap water from the city of

Figure 2: Cross-section of the piezometer installations.

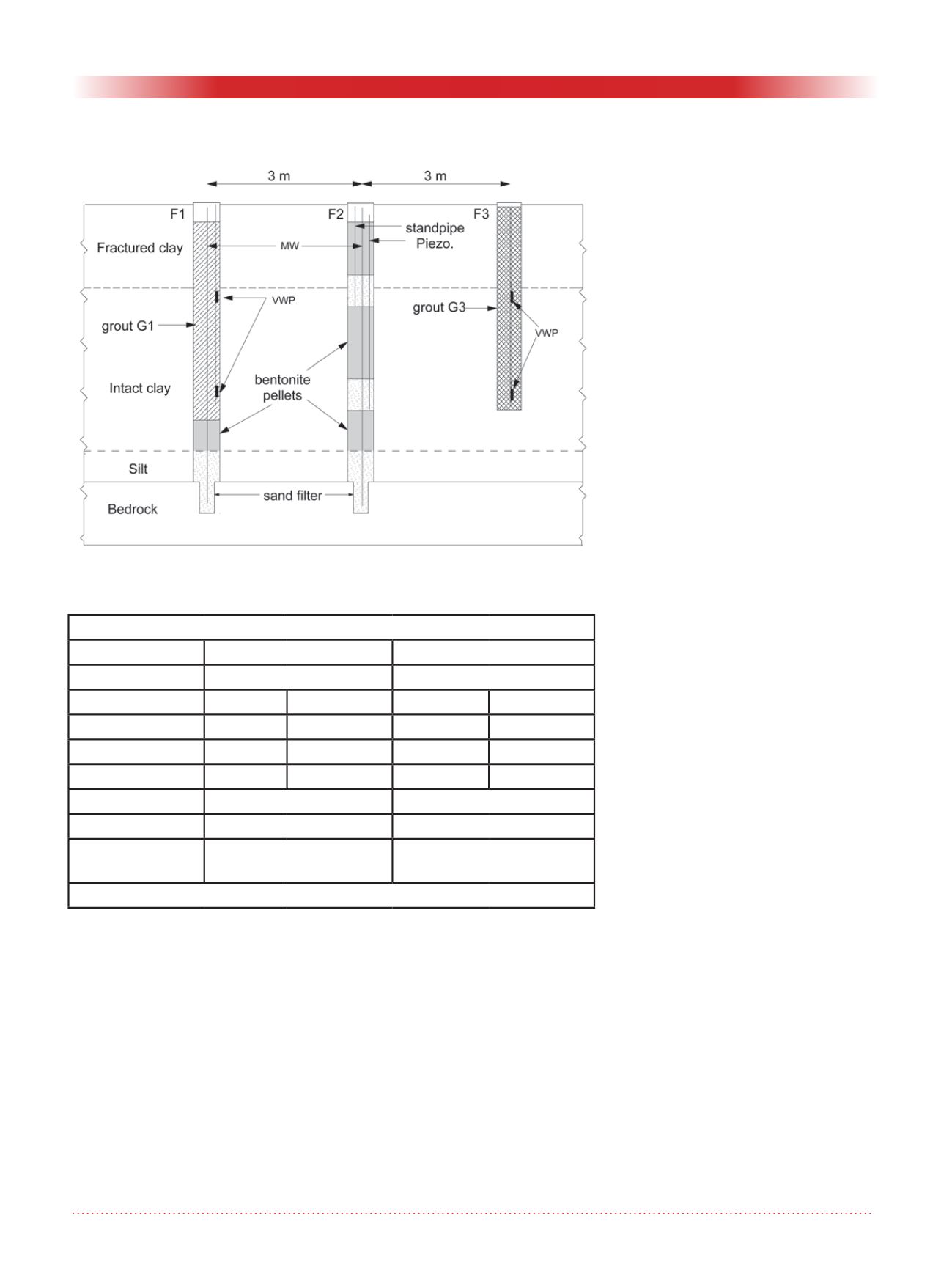

Table 1: Grout recipes, permeability and compressibility for grouts G1 and G3

Borehole F1

Borehole F3

Grout

G1

G3

Material

M (kg)

Ratio

M (kg)

Ratio

Water

120

5

120

6.5

Cement

24

1

18.5

1

Bentonite

28

1.2

7.5

0.4

SP

1

(% of solid)

2.0

none

permeability (m/s)

6.1×10

-9

1.2×10

-6

compressibility

(kPa

-1

)

4.15×10

-5

5.9×10

-5

1

SP = Superplasticizer