Geotechnical News • March 2018

57

GEOHAZARDS

required, site safety, work procedures,

worker experience requirements and

emergency response procedures.

The form is available on the AGHP

website.

A working group is currently design-

ing a corollary guidance document

on how the form should be used,

whom should fill it out, and options

for adjustment and modification. By

implementing the use of SASEs as a

best-practice, together with a job site

assessment (JSA) a comprehensive

job safety evaluation is possible when

accessing steep slopes is required

(Figure 3).

Safety culture and recognition

Best-practice guidelines and the SASE

process are important tools, but are

only of illusory benefit without a

strong safety culture among industry

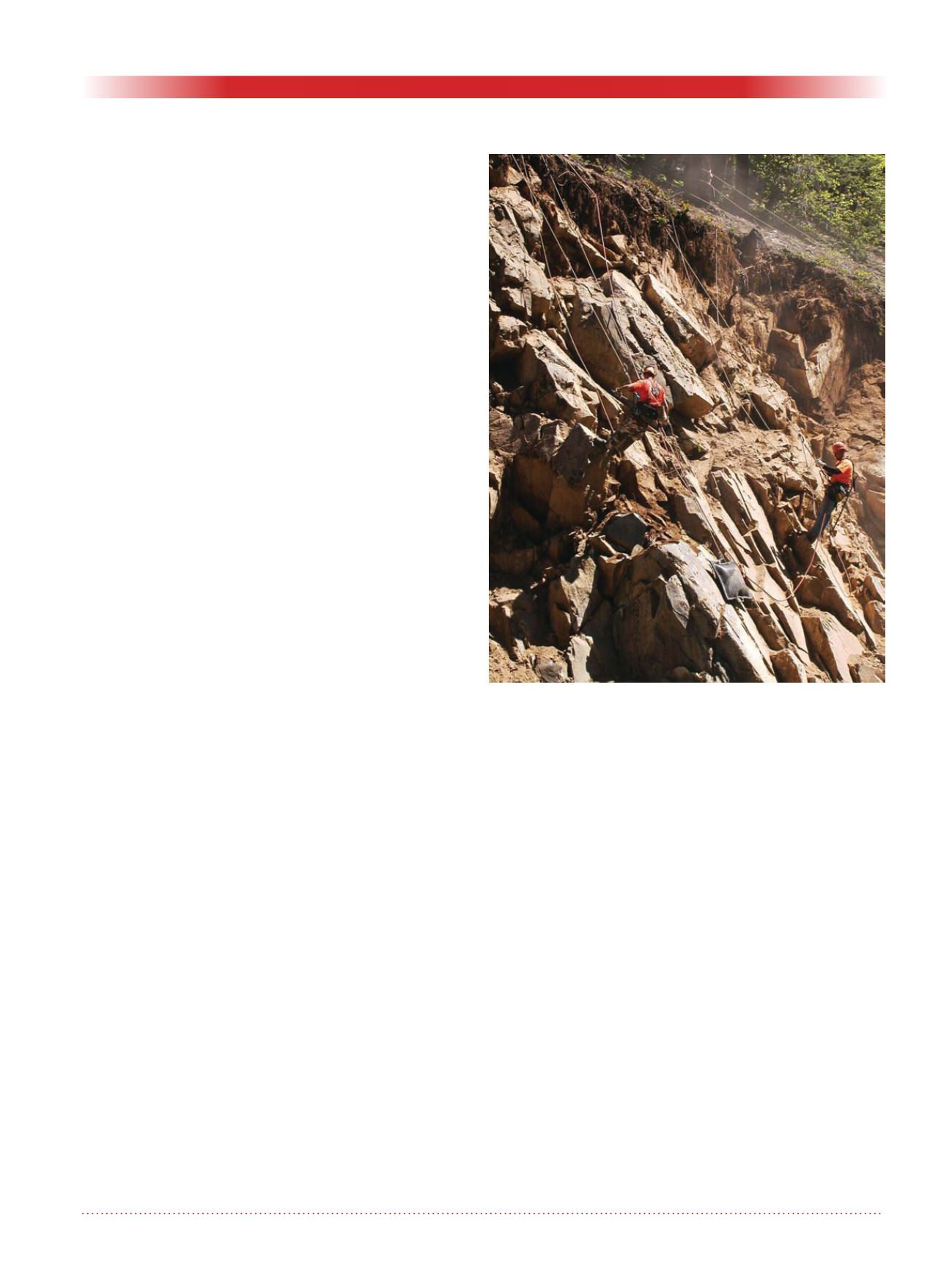

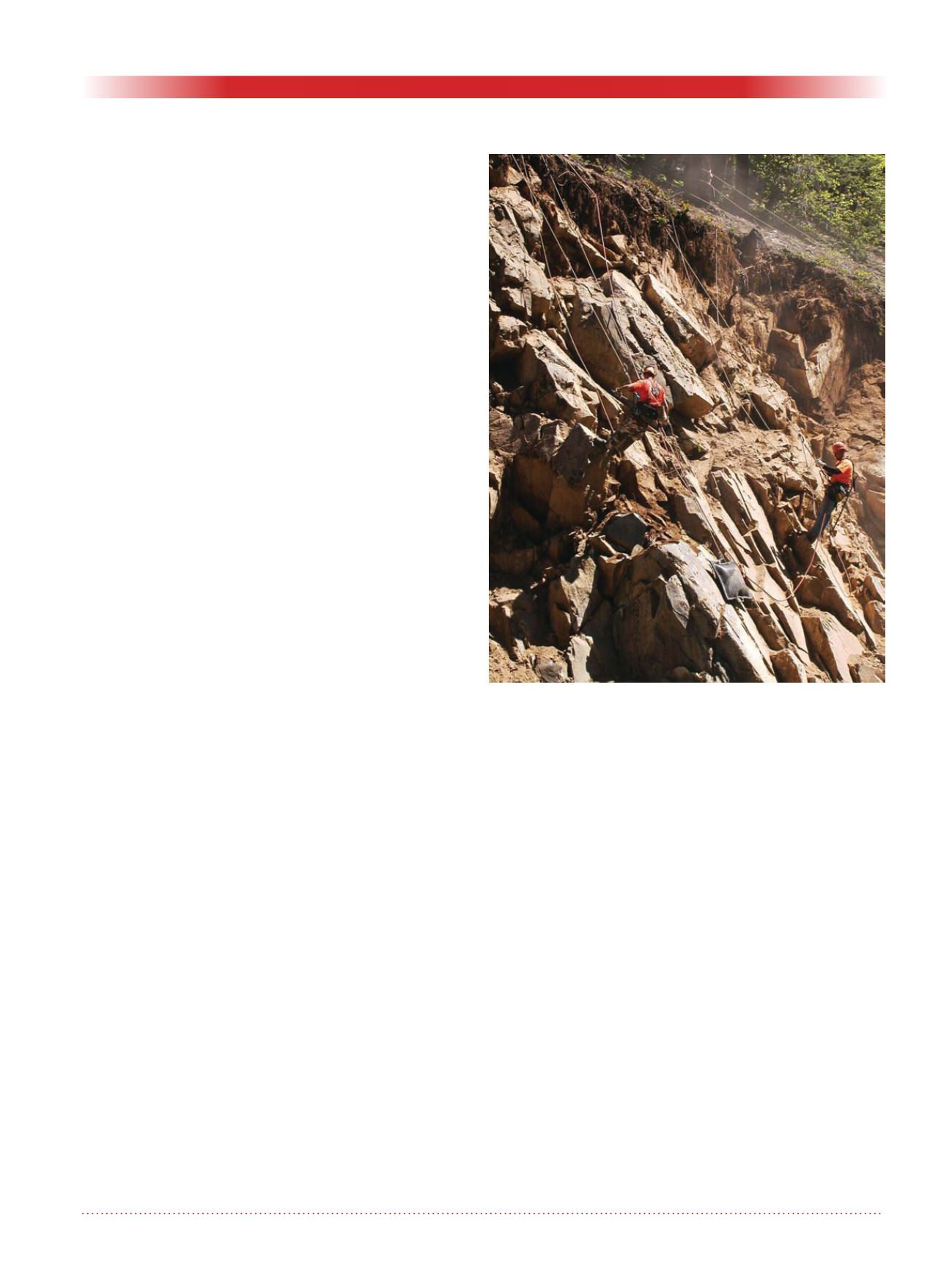

participants. Increasingly, industrial

firms have understood that working

safe need not come at the expense

of production. Workers that know

that they are protected – by their

firm’s process, procedures, training,

approaches, and equipment selection

and maintenance – are able to achieve

high levels of sustainable produc-

tion (Figure 4). And as more owner

agencies become aware of these best

practices, they will inevitably require

that anyone working on their slopes

(including their own employees) do so

with the highest safety standards and

most appropriate certifications. This

process takes time, but the trend in the

North American geohazards mitigation

industry is clear.

To help grow such a culture, the Rope

Access Committee has initiated the

AGHP Safety Recognition Program.

The hope is that by recognizing indus-

try members that are diligent in keep-

ing their rope access workers safe, we

will encourage others to follow. The

public recognition will also help own-

ers have confidence in those who carry

out their work.

The Safety Recognition Program is an

annual review of a company’s safety

program and

performance

metrics. The

first identifies

a commitment

to management

involvement and

commitment to a

firm’s safety pro-

gram, including

specific questions

about whether

the firm has a

written rope

access safety

procedure and

adheres to other

industry best

practices. The

latter identifies

geohazards miti-

gation organiza-

tions that execute

their work safer

than industry

averages based

on Total Incident

Rates and Lost

Time/Modified

Duty Rates statis-

tics.

More information about this program

can be found on the committee’s

webpage.

Summary

The AGHP’s Rope Access Commit-

tee is a group of volunteer individuals

from the geohazards industry with

a passion about making a safe work

environment for those who literally

put their lives on the line while mak-

ing the world a safer place for others.

This diverse group of experts is work-

ing towards establishing best-practice

guidelines, standardizing safety proce-

dures and instilling an industry wide

culture of safety. If the saying “it takes

a village to raise a child” is true, then

it takes an association of volunteers to

keep that child safe! Please share the

culture.

John Duffy,

391 Front Street

Grover Beach, CA 93433

805-440-9062 mobile

805-481-9590 office

Marc Fish, L.E.G.

Asst. Chief Engineering Geologist

Unstable Slopes Unit Manager

WSDOT Geotechnical Office

Construction Division

1655 South Second Avenue SW

Tumwater, WA 98512

360-709-5498

Colby Barrett, P.E.

CEO

GeoStabilization International

4475 East 75

th

Ave.

Commerce City, CO 80222

303-909-6083

Figure 4: Scalers working off of a two-rope system.