Geotechnical News • March 2018

51

WASTE GEOTECHNICS

permanent features on the landscape.

There are over 40 tailings dams in

Alberta, many with extreme failure

consequences. Figures 1 and 2 show

examples of TSFs in Alberta, at a coal

and oil sands mine, respectively.

Dam operators must comply with

regulatory requirements to construct,

operate, and monitor active tailings

dams. As part of this, operators must

make resources and personnel avail-

able to manage and monitor the facili-

ties. Failure modes of active dams

are well understood, and contingency

plans are put in place in case the dam’s

performance deviates from what is

expected.

In Alberta, the safe operation of coal

and oil sands mines—and their tailings

dams and ponds—is regulated by the

Alberta Energy Regulator (AER). The

AER ensures that operators construct,

operate, monitor, and decommission

their tailings dams and ponds respon-

sibly; regulation and compliance are

enforced through enactments, regula-

tions, standards, and directives. For

oil sands tailings dams in Alberta in

particular, their design, construction,

operation, and management systems

are advanced and highly regarded

internationally (Morgenstern 2010).

Decommissioning tailings dams

Many of Alberta’s early tailings dams

were designed with little consideration

of their long-term behaviour (i.e.,

when the dam is no longer active), but

we now recognize that the post-mining

life of these structures is significantly

longer than their active life. Some

higher risk dams may prove difficult

to re-integrate into the surrounding

environment.

It is expected that a safely closed and

reclaimed tailings dam will no longer

function as a dam; that is, it will no

longer retain fluids or liquefiable

tailings, nor should there be unaccept-

able consequences if a failure occurs.

It is also expected that the reclaimed

structure will be compatible with

natural landforms in the region and

will be suitably resistant to processes

of landscape evolution, including

slope instabilities, surface erosion

from wind and rain, erosion due to

stream or river flow and floods, animal

burrowing, and internal seepage. The

operator must also identify and plan

for foreseeable future climate condi-

tions, land uses, and anthropogenic

activities.

Many institutions, geotechnical

conferences, and research facilities,

as well as organizations and programs

such as the Canadian Dam Associa-

tion, the International Committee on

Large Dams, and the United Nations

Environment Programme, have

advanced our knowledge about the

decommissioning and delicensing

process for tailings dams; however,

we continue to know very little about

the aging processes that tailings dams

undergo in perpetuity. This informa-

tion gap poses an unquantified long-

term environmental risk, public safety

risk, and financial liability to opera-

tors, the public, and the AER. Until we

fully understand the conditions leading

to post-operation risks, such as dam

failures, diligence and prudence are

required by the operator and regulator.

Kupper et al. (2013) proposed a risk-

based approach to delicensing oil

sands tailings dams that identified risk

considerations, defined assessment

criteria, and described how to apply a

risk assessment process. Eaton (2016)

reviewed a number of dam failures

that occurred between 1972 and 2015,

and related the failures to deficiencies

in the dam safety management system,

described elements of the AER Dam

Safety Program and Tailings Manage-

ment Framework, and discussed tail-

ings dam safety and decommissioning.

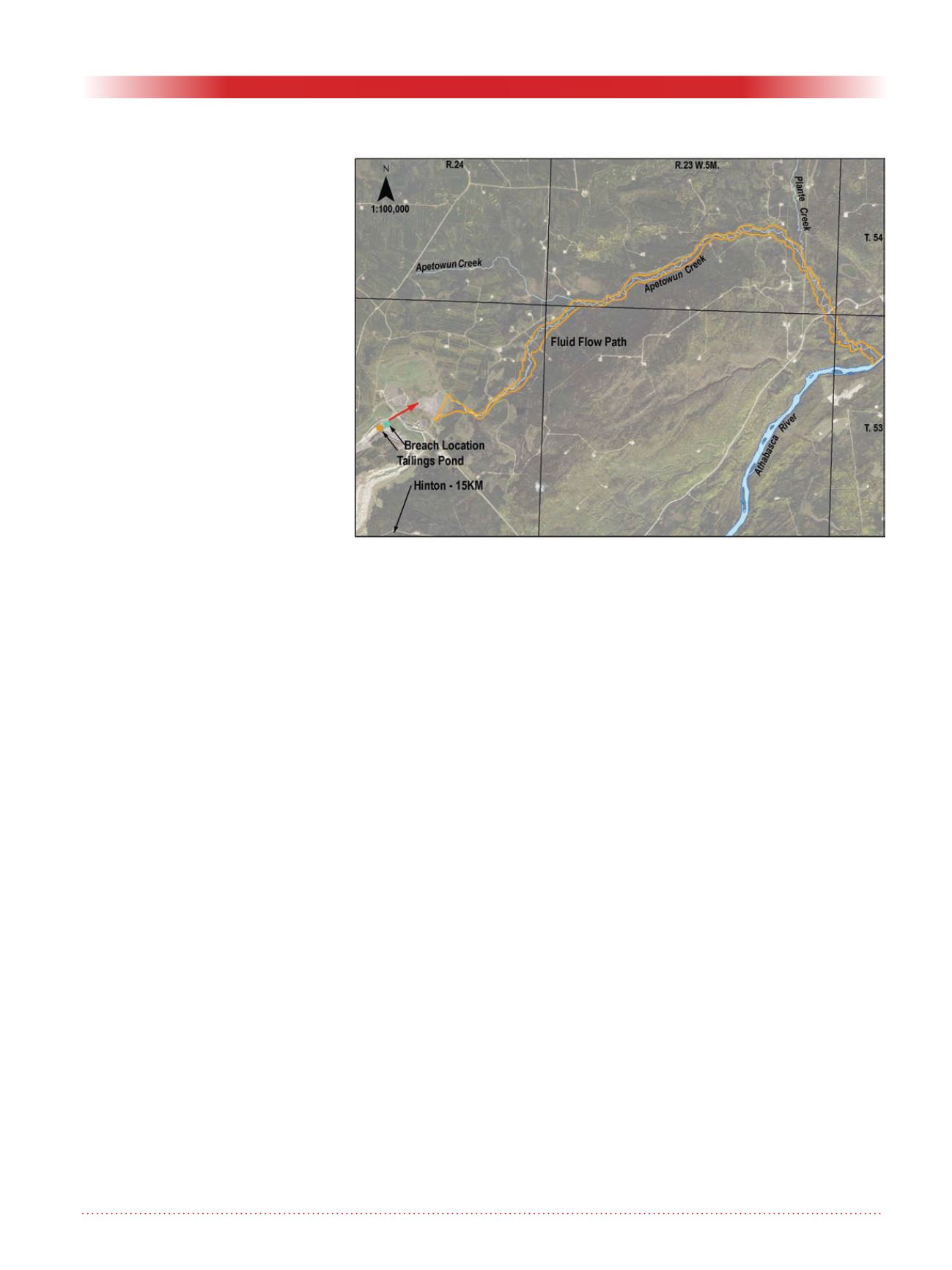

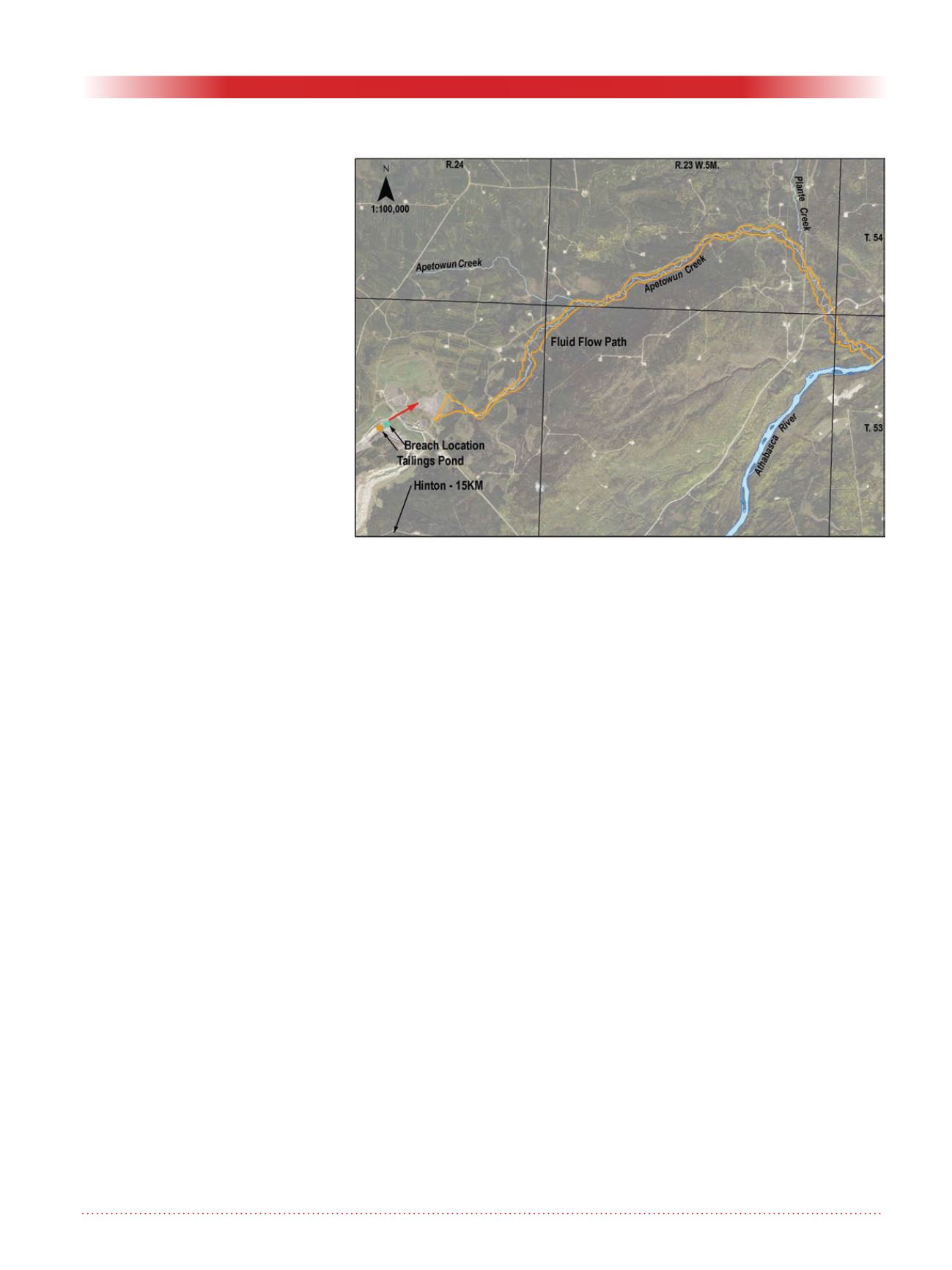

The Obed Dam failure and

creative sentence

An event in 2013 brought immediate

attention to the need for long-term risk

assessment and monitoring of tailings

dams through the decommissioning

and reclamation process. On Octo-

ber 31, 2013, a tailings dam failed at

the Obed Mountain coal mine, about

15 km northeast of Hinton, Alberta

(Figure 3). The failure occurred while

the mine was being monitored and

maintained after operations were sus-

pended in 2012 due to poor economic

conditions. About 670,000 m

3

of

waste water and 90,000 tonnes of fine

Figure 3. Plan view of the Obed Mountain coal mine showing the breach

location and flow path of tailings fluids to the Athabasca River. (Source:

Alberta Energy Regulator)