Geotechnical News • March 2018

55

GEOHAZARDS

Safe work on dangerous slopes

John Duffy, Marc Fish, and Colby Barrett

Prologue

In 2013 a group of engineering,

geologic and geotechnical

consultants, contractors,

manufacturers and stake

holders came together to form

the Association of Geohazard

Professionals (AGHP). The

concept was a diverse body

that could promote material

and application standards, best

practices, safety practices, and

knowledge transfer in North

America. The association has

grown steadily since, with much

of its activity focused around

committees dealing with various

aspects of the industry such as

debris flow mitigation, geohazard

monitoring, anchor design and

testing, material testing and

dangerous slope access and

safety.

The Rope Access Committee is

one of the first committees to

have formed. John Duffy (Yeh

and Assoc., formerly California

Department of Transportation)

and Marc Fish (Washington State

Department of Transportation)

are the committee co-chairs,

having a combined total of 50

years working on and around

dangerous slopes. The committee

consists of representatives

from government, academics,

consultants, contractors and

geohazard system manufacturers.

.

Introduction

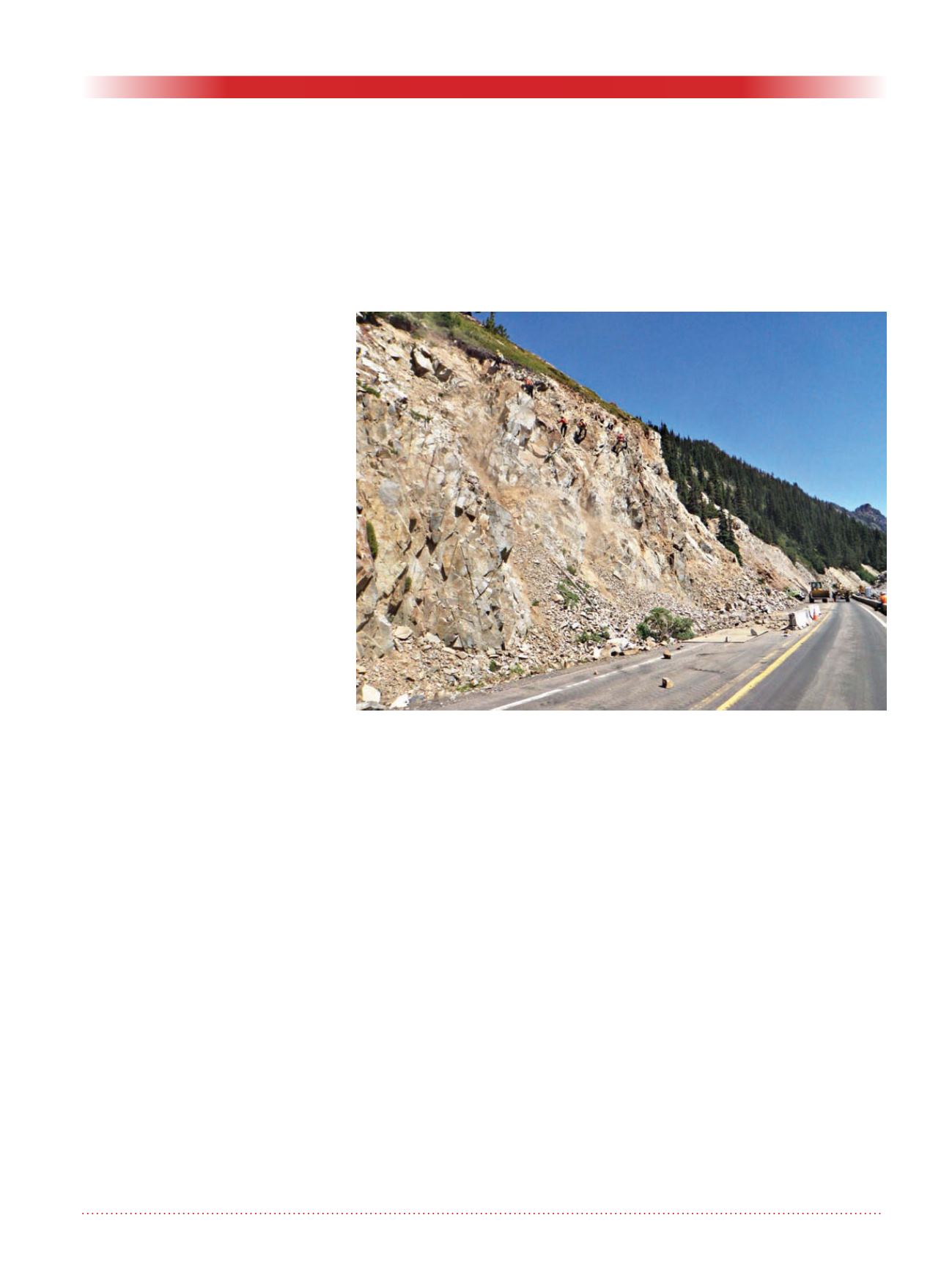

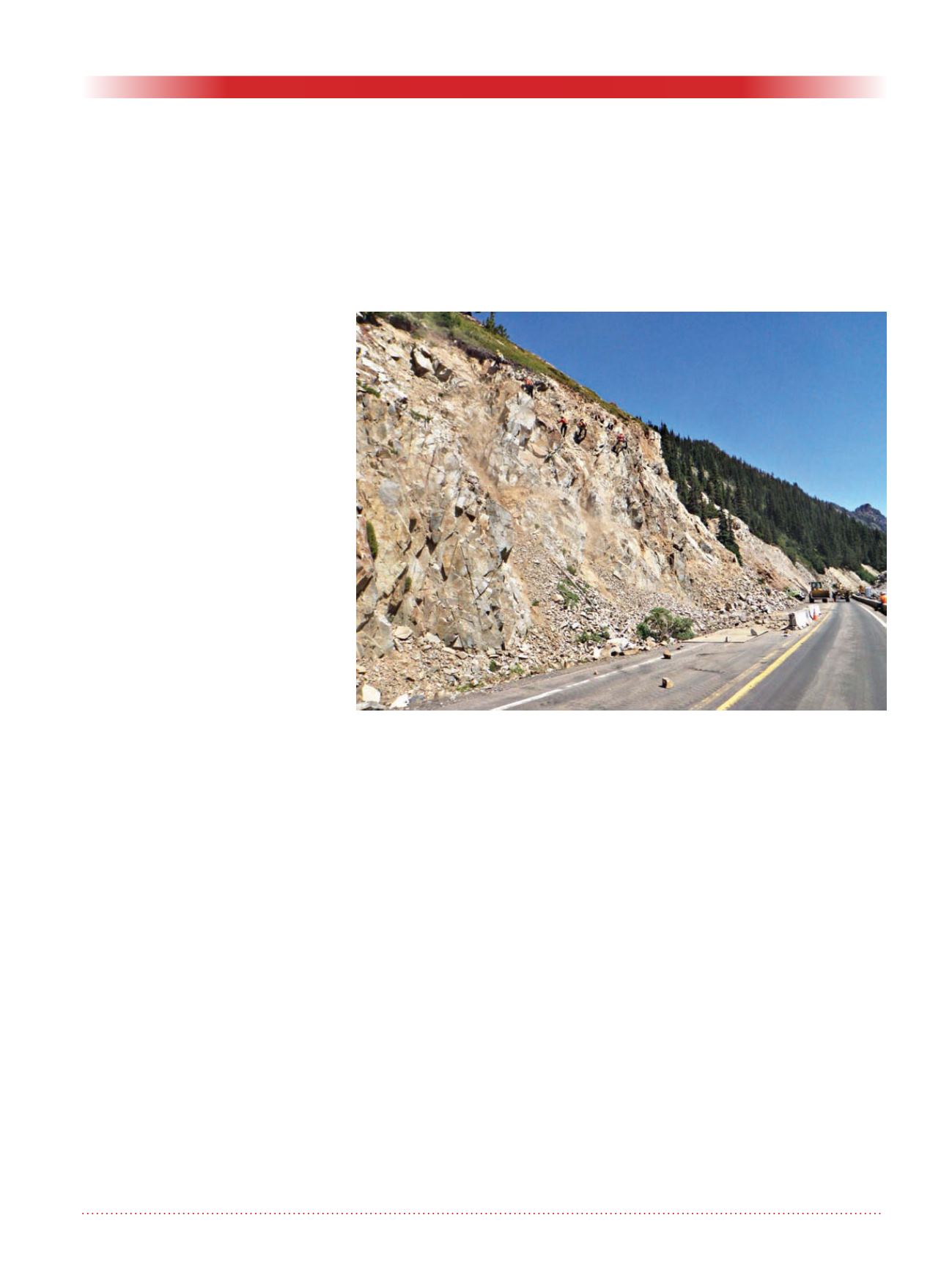

The mitigation of many geohazards

involves the movement of people and

machinery on or within the affected

areas of steep, unstable slopes (Figure

1). The very nature of the work means

that lives are being put at risk at every

stage of mitigation, whether it is in the

course of preliminary site investiga-

tions, during construction, or carry-

ing out inspection or maintenance of

mitigation measures. Such activities

are by no means a new phenomenon,

but as the geohazard industry has

progressed over the years, there has

never been a widespread adoption of

rope access protocols specific to the

unique requirements of the industry.

Instead, geohazard professionals have

been left to draw on safety procedures

and training originally developed for

other applications such as recreational

climbing, search and rescue, arborists,

security, avalanche control, and man-

made structures. Other than the fact

that all these activities share the use of

rope systems for mobility, they differ

greatly in practice. The skills, tech-

niques and equipment that make one

activity safe cannot simply be trans-

ferred to another with an expectation

of the same results. The Rope Access

Committee is trying to establish rope

access protocols and cultures that will

fill make the industry safer, while at

the same time allow professionals to

work efficiently.

Rope access best-practice

Social acceptance of exposing

employees to hazardous conditions on

a worksite has reduced dramatically

over the last century and employers

are increasingly focused on protecting

the worker from harm while carry-

ing out their tasks. Safety standards

are frequently set by State/Provincial

or Federal public agencies, however,

these policies can be absent, vague,

Figure 1: Scaling operations along Highway SR 410 in Washington.