52

Geotechnical News December 2010

WASTE GEOTECHNICS

Geotechnical engineers have long

understood the importance of observ-

ing pore water pressures and embank-

ment deformations in tailings contain-

ment facilities. This is because these

data correlate well with several types

of failure and as such provide a basis

to rectify the situation throughout the

mine life and beyond (Peck, 1969).

We must learn to earn the confidence

of multi-disciplinary teams, which are

operative at mine sites, to ensure the

safety of tailings dams. Perhaps, we

have learnt that message with regards

to seismic liquefaction (that results in

swift and drastic events), where fail-

ures of this type have dropped from

14% in pre-2000 cases to zero in post-

2000 cases:the 2010 Chilean earth-

quake of magnitude 8.8 did not cause

any failure. Good earthquake designs

are partly because of our understand-

ing of dynamic loading such as blasting

that is common practice at mine sites.

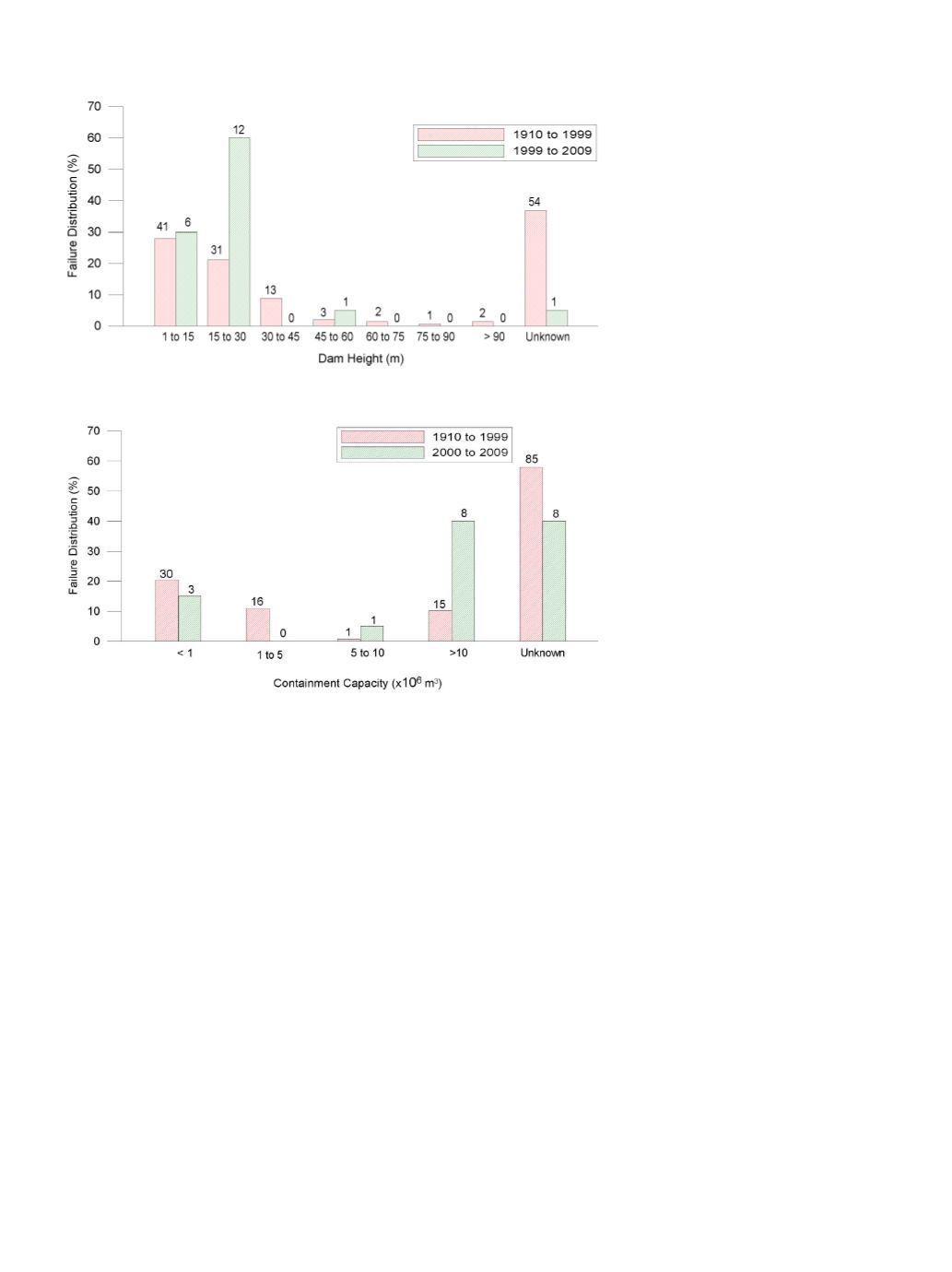

Figure 4 shows the distribution of

tailings dam failures by dam height.

Failures are found to mainly occur in

dams with heights of up to 30 m. A

plausible reason may be that unconsol-

idated materials with high pore water

pressures in such relatively low dams

(possibly in their early stages of devel-

opment) are yet to develop adequate

shear strength to counter the resisting

forces. This is especially the case when

the tailings dams are constructed using

the upstream method that is still a com-

mon practice in some of the developing

countries (Vick, 1999). Further, a com-

parison of the two time groups reveals

that failure in dams of up to 15 m height

increased from 28% to 30% whereas

failure in dams with heights between

15 m to 30 m increased from 21% to

60%. The recent increase in failure of

such dam heights may be attributed to

the combined effect of rapid dyke con-

struction along with poor monitoring.

This is particularly true for some of

the re-opened mines (due to increased

commodity prices in the 2000s) for

which the tailings containment facili-

ties were raised based on pre-closure

construction practice.

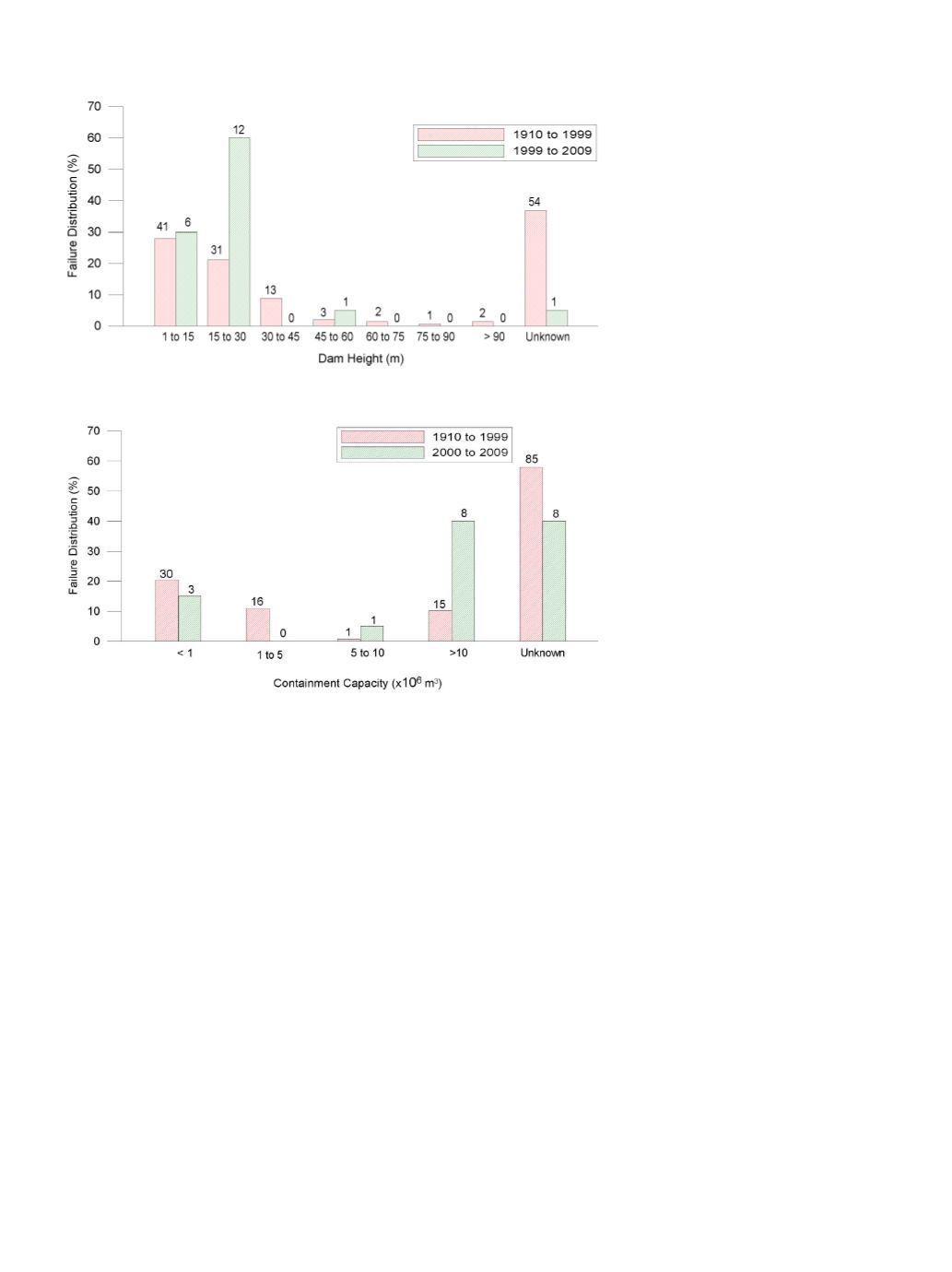

Figure 5 gives the distribution of

tailings dam failures by containment

capacity. This figure corroborates well

with data in the previous figure by

indicating that about 31% (pre-2000

events) of failures occur in small to

intermediate size facilities that contain

up to 5 x 10

6

m

3

of tailings. The drop

in such events to 15% in the post-2000

cases may be ascribed to containment

geometry requiring low dams. Similar-

ly, the increase in tailings dam failures

from 10% to 40% in large dams (stor-

ing in excess of 10 x 10

6

m

3

of tailings)

should be due to one or more of the

afore-mentioned reasons.

Impact of Failures

Figure 6 summarizes the failure

distribution by tailings release amount.

The figure illustrates that a significant

portion (29% for pre-2000 cases and

40% for post-2000 cases) of the dam

failures released up to 0.5 x 10

6

m

3

of tailings to the environment. This

correlates well with data depicted in

Figures 4 and 5 where a comparable

number of incidents fell in small to

intermediate size dams. The current

figure shows that usually about

one-fifth of the contained volume

is released. Even such volumes are

sufficient to cause extensive damage to

life, property, and health. For example,

0.5 x 10

6

m

3

of released tailings are

enough to drown about 1200 North

American style single-family homes.

Figure 7 illustrates the distribution

of tailings dam failure by socio-eco-

nomic impact.

Failures were assigned

to a certain parameter that best de-

scribed the actual incident. The main

impacts were found to be environ-

mental pollution, loss of life, and in-

frastructure damage. Parameters such

as environmental pollution and infra-

structure damage were found to respec-

tively decrease from 52% and 20% for

pre-2000 events to 35% and 15% for

post-2000 cases. This is in accordance

with the above findings that about one-

Figure 4. Failure distribution by dam height.

Figure 5. Failure distribution by containment capacity.