58

Geotechnical News December 2010

GEO-INTEREST

My reasoning from there went like

this: Water pressure exerted on the base

of the cylinder, and felt by the scales,

was obviously a response to the weight

of the falling ball above. But why the

delay ? Why not the full weight right

away ? There had to be another force

involved temporarily, acting as a buf-

fer. I couldn’t think of anything to fit

the bill other than viscous drag. And

such a drag force is known to be gener-

ated between a solid and a fluid in rela-

tive motion. Fluid Mechanics had this

all wrapped up generations ago so, as

you’ll see, it was just a matter of go-

ing to their comprehensive literature to

work things out from there.

My scales was not sensitive enough,

nor did it respond fast enough, to let me

see what was happening between these

two values. For this I needed to find

a good laboratory in some university

which would listen to a maverick with

an odd notion about the genesis of pore

water pressure.

UBC Test Setup & Prediction

Fortunately for me my good friendYogi

Vaid is Professor Emeritus at UBC and

still had access to the fundamental

soils laboratory at UBC which gained

recognition as a world leader in

triaxial testing during his tenure. Yogi,

who was well used to listening to me

ramble on about my abiding prejudice

that pore water pressure had to come

from relative motion between the

phases, was happy to help. Here I got

not only the better scales and a better

readout device that I needed, but also

the assistance of Scott Jackson and his

experimental expertise.

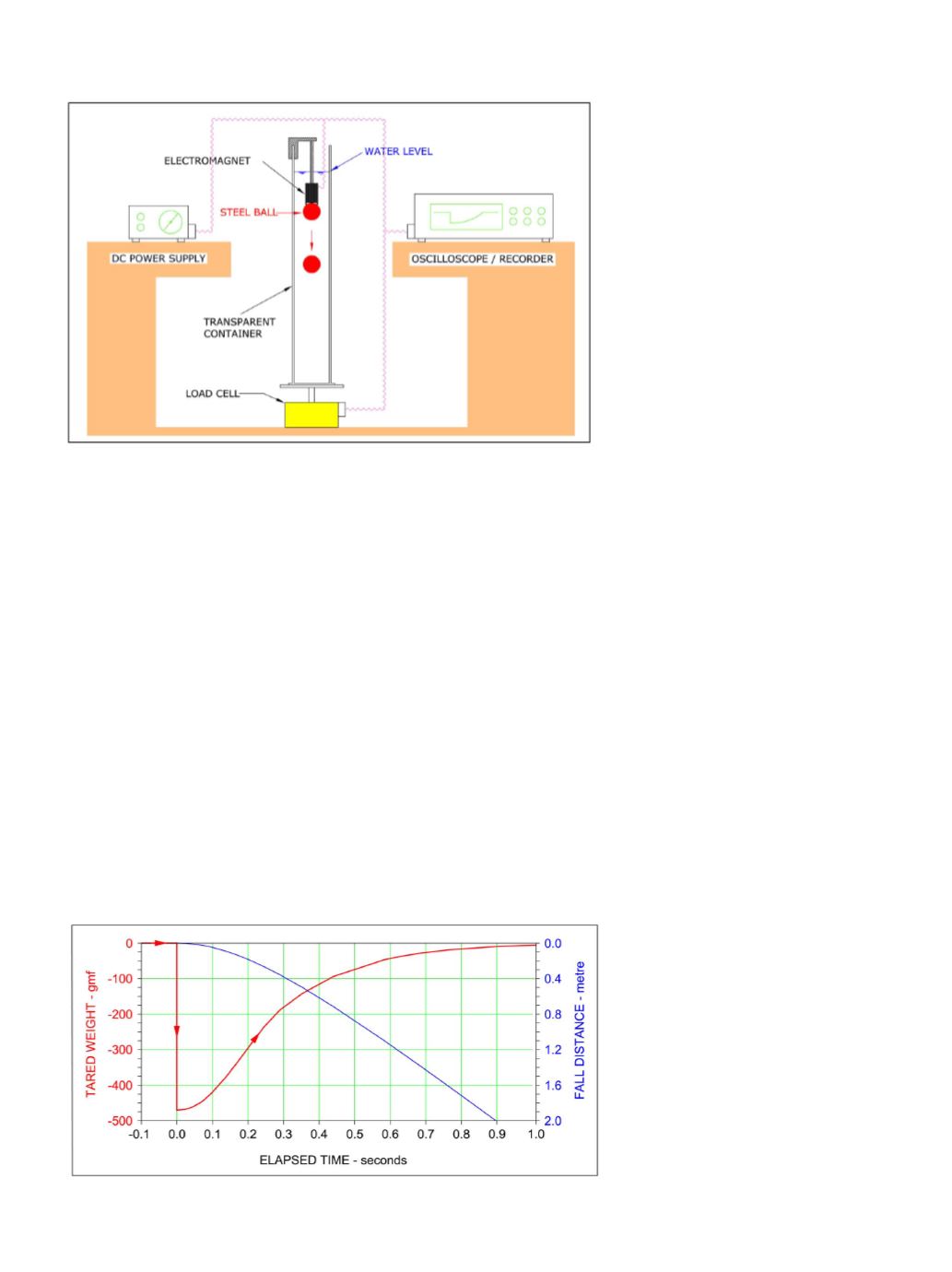

For this opportunity I designed the

apparatus shown in Figure 3. The de-

sign intent was to discover what was

going on during the intermediate period

between releasing the ball and the time

its weight showed up on the scales. I

decided the best thing to do was to

record only one thing – the weight

of the full system, that is, ball, water,

and apparatus hardware. This involved

some compromises. To get sensitivity

in the readout the weight of the water

had to be kept within reasonable limits

and this meant using a cylinder which

was a bit shorter and narrower than

I’d have liked. Also the ball had to be

quite heavy. I decided on a 2 inch ball

bearing, using steel rather than ceramic

because of its far greater buoyant mass

density. Steel had the added advantage

that it could be held in place by an elec-

tromagnet which could also drop it with

a flick of the switch. The whole system,

ball and all, sat on a load cell which was

connected to an oscilloscope and a data

recorder. All was necessary after things

were setup was to power up the record-

er and switch off the magnet.

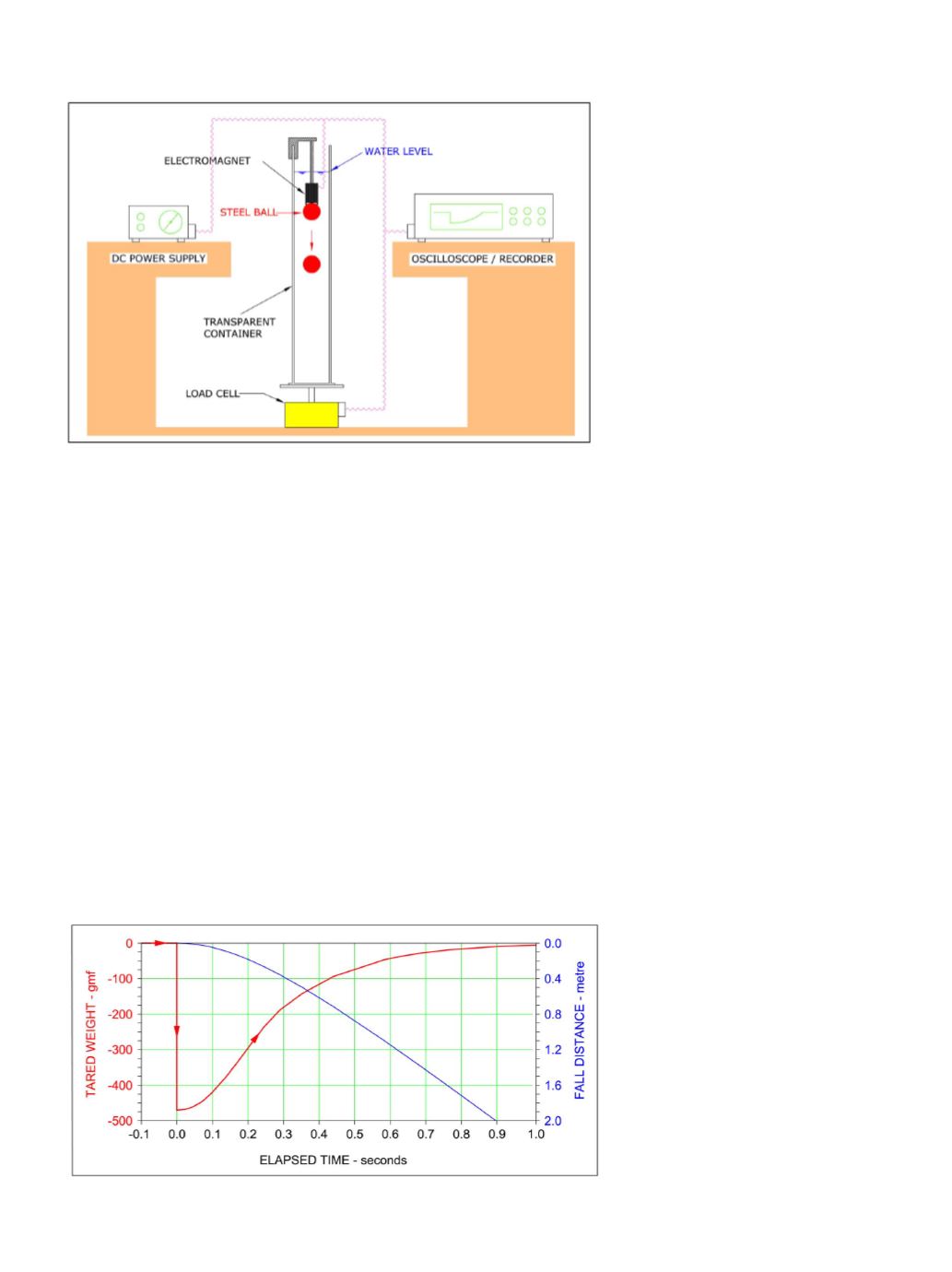

In lab testing, as in site investigation

sampling and construction instrumen-

tation, you get much more out of it if

you have already thought enough about

what to expect to let you risk a predic-

tion. With this in mind I calculated the

weight history I anticipated on the ba-

sis of the hydrodynamics that I thought

were going on. This prediction is shown

on Figure 4. I wanted it to be a clear

understanding that if the prediction was

right then the hypothesis was justified,

and if the prediction was wrong then

it was time to forget the whole thing.

Needless to say I wouldn’t be writing

this if it turned out all wrong.

In the Next Article

In the next of this series I’ll give the

results of the UBC test and compare

them with the prediction made

beforehand. And there I will also lay

out the reasoning behind the predictive

method and explain how the required

calculations were made.

W.E.Hodge

Geotechnical Engineer

P.Eng., M.ASCE

P.O. Box 287, Lumby, BC, V0E 2G0

(778) 473 4505

Figure 4. Prediction of UBC test results.

Figure 3. UBC laboratory test setup.