60

Geotechnical News December 2010

GEO-INTEREST

dehydration) begins at 550-600 °C to

produce disordered metakaolin, Al-

2Si2O7, but continuous hydroxyl loss

(-OH) is observed up to 900 °C and has

been attributed to gradual oxolation

of the metakaolin. Because of historic

disagreement concerning the nature

of the metakaolin phase, extensive re-

search has led to general consensus that

metakaolin is not a simple mixture of

amorphous silica (SiO2) and alumina

(Al2O3), but rather a complex amor-

phous structure that retains some lon-

ger-range order (but not strictly crystal-

line) due to stacking of its hexagonal

layers.

2 Al2Si2O5(OH)4

→

2 Al2Si2O7

+ 4 H2O

Further heating to 925-950 °C con-

verts metakaolin to a defect aluminu-

im-silicon spinel, Si3Al4O12, which is

sometimes also referred to as a gamma-

alumina type structure:

2 Al2Si2O7

→

Si3Al4O12 +

SiO2

Upon calcination to ~1050 °C, the

spinel phase (Si3Al4O12) nucleates

and transforms to mullite, 3 Al2O3 •

2 SiO2, and highly crystalline cristo-

balite, SiO2:

3 Si3Al4O12

→

2 Si2Al6O13 +

5 SiO2

Mixing of Different Materials

The main material mixed in this case

is the dry kaolin. It is combined with

optimum moisture content, due to the

compaction test in different tests. Then

it is mixed by kneading until cohesion

soil is achieved. The sizes of the bricks

to be made are 10cm×10cm×10cm and

the mixture is placed in three layers in

steel moulds. They consist of two layers

composited of additional materials that

are the shred geogrids are placed at 1/3

and 2/3 of its height.

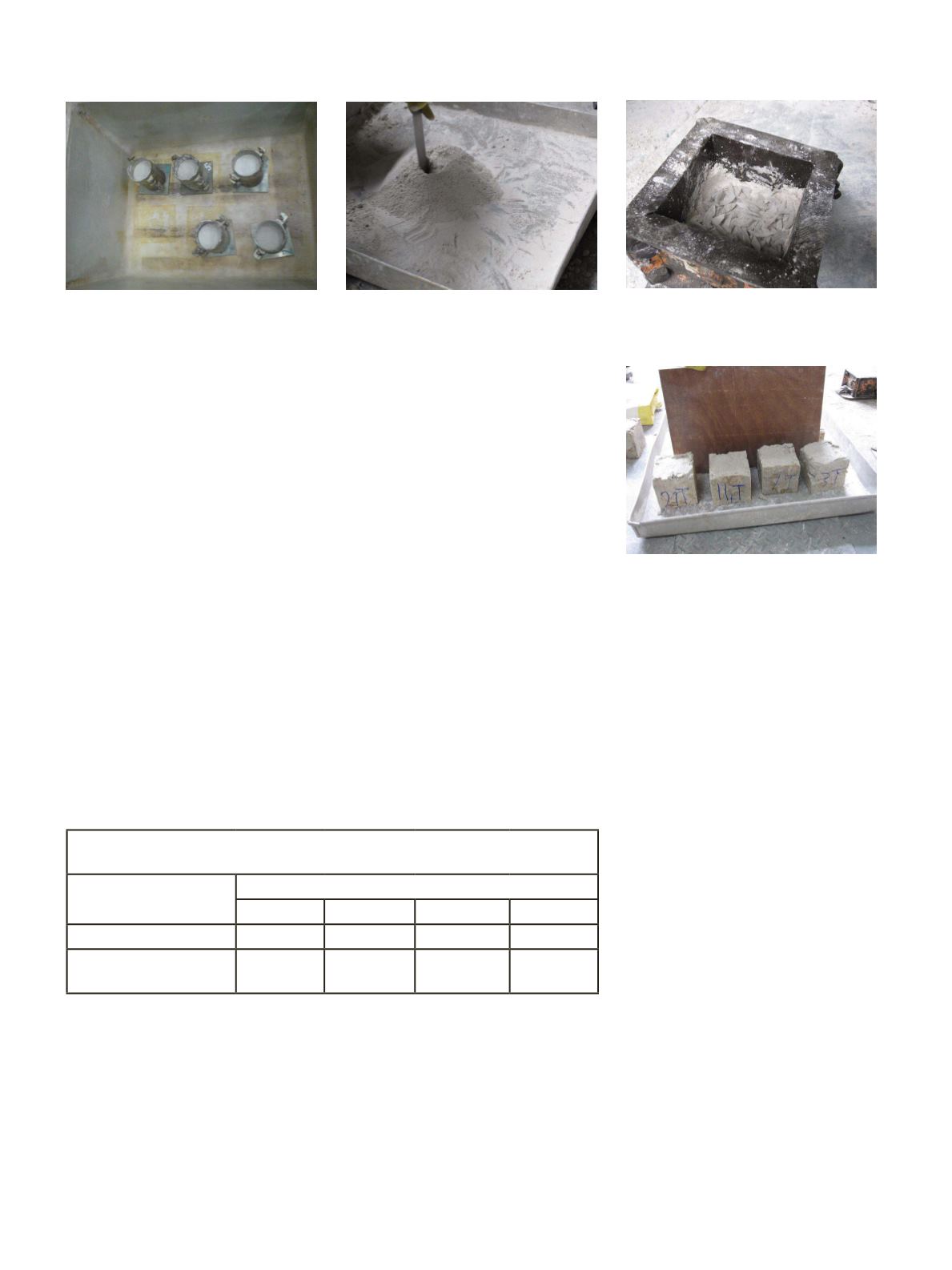

Test of Mud Bricks

The mud bricks were used for 4 tests

and taken out from the moulds. Then

they were tested for compressive

strength for 3,7,14 and 21 days.

Conclusion

The compressive strength test s results

on mud bricks that have additional

material, such as shred geogrids are

illustrated in table 1. The results

of compressive strength show that

performance of shred geogrids are

better than normal mud bricks by

time passing. They show an increase

of the compressive strength until 14

days and then a decrease. The main

reason that causes this decrease is the

moisture range, due to the wet climatic

conditions of Malaysia. The shape of

additive materials can be as well, a

factor that causes this decrease in the

compressive strength in a long period

of time. The first reason, regarding to

the moisture has the highest impact on

this compressive strength. The shred

tires increased the status of tension

in mud bricks. The performance of

shred geogrids increased properties

of compression in different cases,

although performance of mud bricks

without addition material wasn’t good

in earthquake of Bam-2003 in Iran but

there is a hope that shred tires mud

brick can carry out high strength in the

future.

Reference

[1] Bellotto, M., Gualtieri, A., Artioli,

G., and Clark, S.M. (1995). “Ki-

netic study of the kaolinite-mullite

reaction sequence. Part I: kaolinite

dehydroxylation”. Phys. Chem.

Minerals 22: 207-214.

[2] Deer, W.A.; Howie, R.A.; Zussman,

J. (1992), An introduction to the

rock-forming minerals (2 ed.), Har-

low: Longman, ISBN 0582300940

Figure 5. View of different cases in

compression test.

Table 1.The results of compressive test of mud bricks with shred geogrids

and normal mud bricks.

Type

Days

3

7

14

21

Kaolin + water

1.90

N/mm

2

2.94

N/mm

2

2.52

N/mm

2

1.49

N/mm

2

Kaolin + Water + Shred

Geogrids

1.91

N/mm

2

2.57

N/mm

2

2.62

N/mm

2

1.81

N/mm

2

Figure 2. Compaction test of kaolin.

Figure 4. View of shred geogrid in 1-3

layer of mould.

Figure 3. Mixing of kaolin with opti-

mum moisture content.