22

Geotechnical News September 2011

GEOTECHNICAL INSTRUMENTATION NEWS

(RSP) measurements, thanks to a laser

beam aimed directly on the surface.

Nowadays two methods of comput-

ing surface settlement exist:

• The standard method (single points

directly measured by the total sta-

tion)

• The mesh method (treatment of a

number of points to geographically

smooth the results).

We have used both methods ex-

tensively in Europe over the past few

years. Both have advantages and draw-

backs.

This article presents the generalities

of the technique, its potential limita-

tions and requirements, and then briefly

presents two sites where both standard

and mesh methods were used.

How does it Work?

3D monitoring with a RTS consists

of a zero measurement of a network

of points measured in three fixed

directions to be able to follow this

network over time. Preferably the

baseline measurement is performed

previous to any construction work.

A record of the weather conditions

(temperature, pressure and humidity)

and all the factors that could influence

the measurements is very important.

An automatic 3D monitoring system

able to measure surface deformation 24

hours a day is made up of a total station

equipped with a reflectorless distance

meter and a personal computer which

can be operated remotely with specific

software able to drive

the total sta-

tion to predetermined locations of the

points that are to be monitored. We will

refer to this entire system as Reflector-

less Robotic Total Station (RRTS) for

the rest of this article

1

.

1

The commercial name of the whole

system as developed and used by Sol-

data is “CENTAURE”. This name now

appears regularly in articles and speci-

fications, but for the rest of this article

and for future generic use we suggest

the use of the term RRTS for Reflector-

less Robotic Total Stations. As for RTS,

the term RRTS will apply both to the to-

tal station being used and to the whole

system, including all software and data

treatment processes.

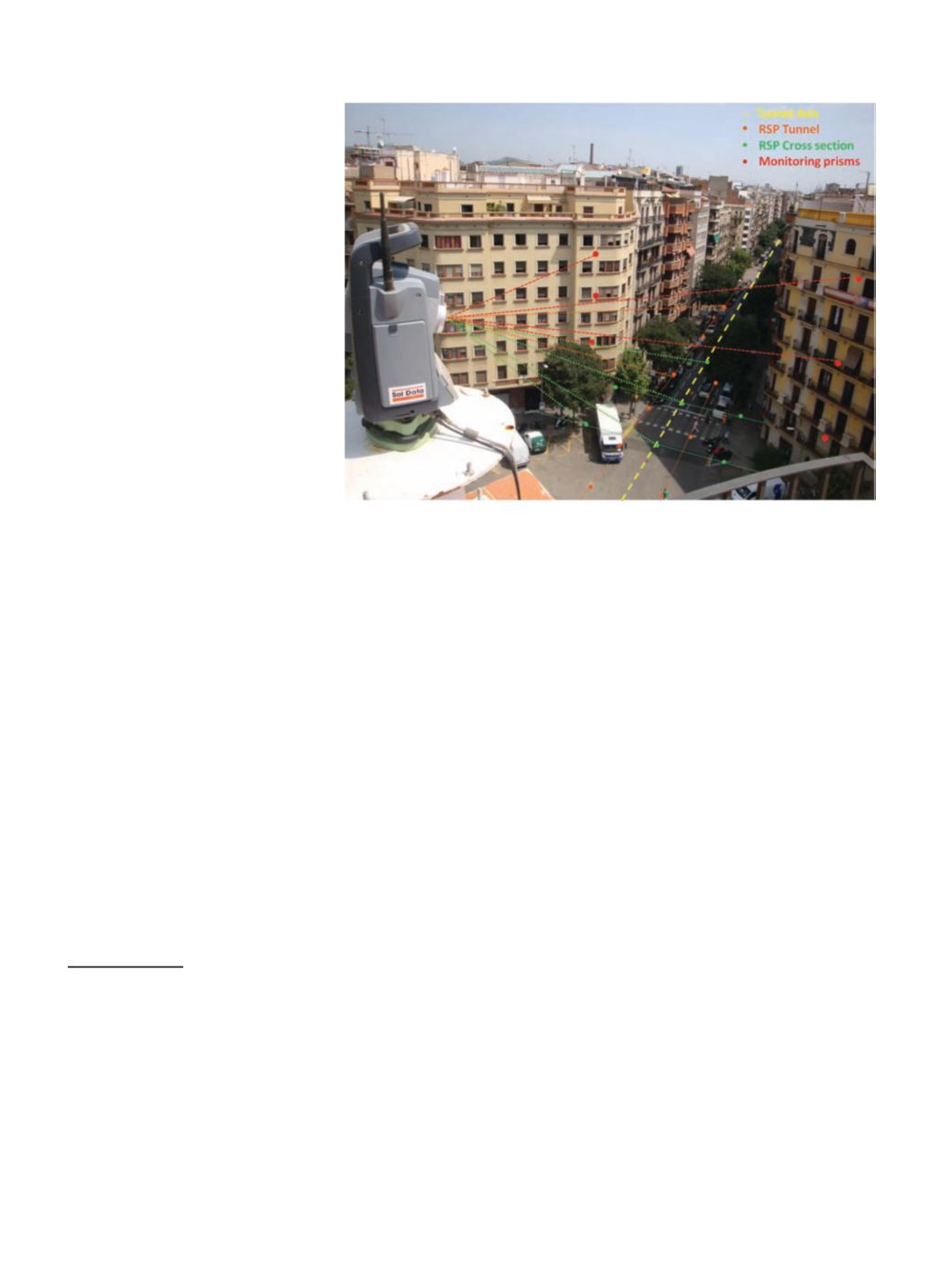

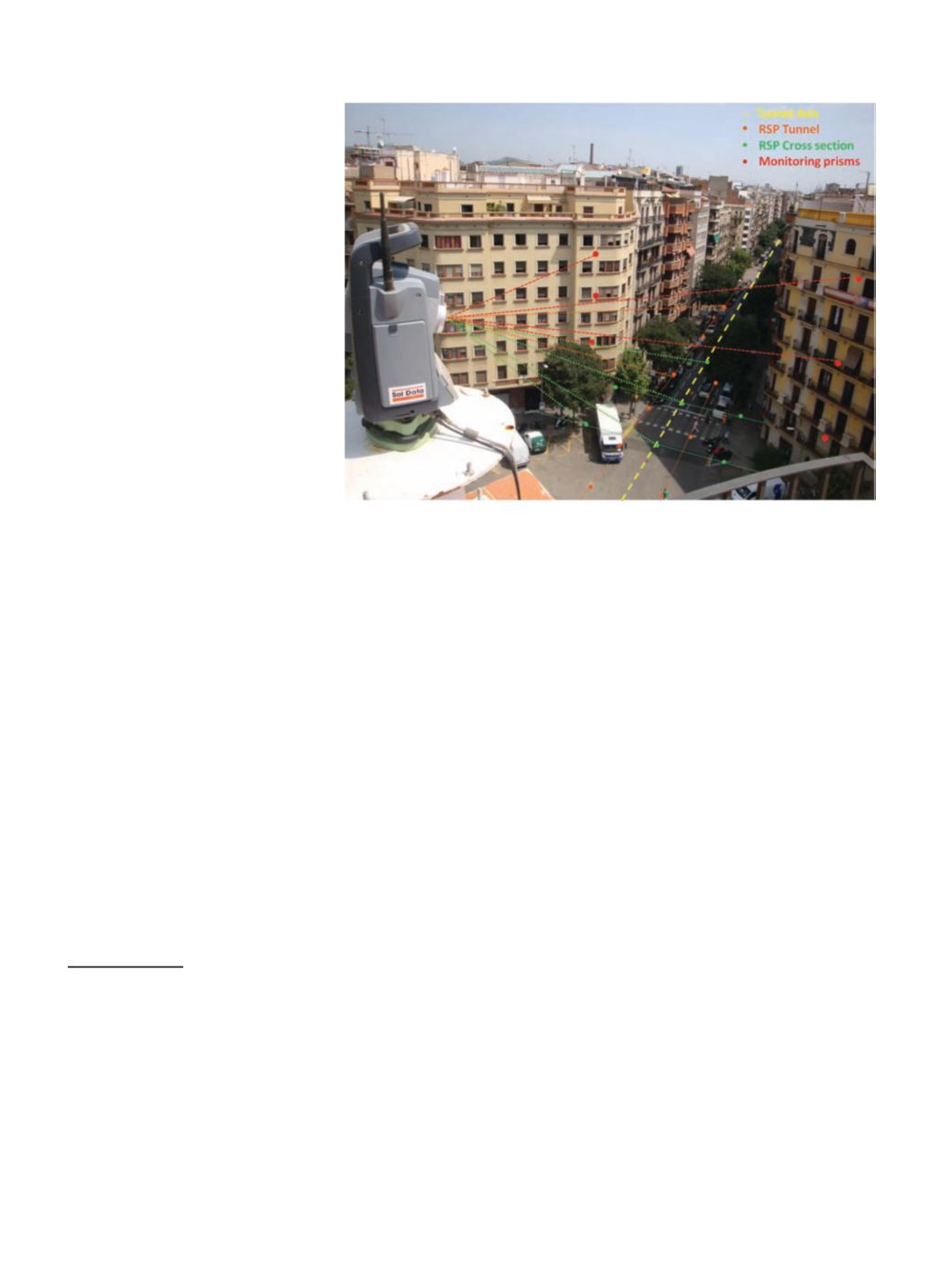

During each monitoring cycle the

instrument sights at two or three groups

of points (see Figure 1):

• RSPs on a flat, homogeneous and

planar surface for which vertical

deformation is to be monitored.

RSPs are not physically marked

and are not physical objects: They

are just a location on the ground at

which the RTS is sighting.

• The stable reference prisms, which

permit computation of the correct

position and the orientation of the

total station.

• If necessary, the same total station

and software can sight monitoring

prisms installed on structures to be

monitored in 3D, the same as for a

standard RTS

On completion of the cycle (typi-

cally 20-40 minutes, depending of the

number of points), the raw data are sent

to the database via Wi-Fi or 3G.

If both the availability and the dis-

tribution of the values meet the quality

criteria then the height of the RSP is

calculated and can be published in real

time via a web-based GIS. Treatments

include sliding statistical analyses of

the data. These methods allow removal

of any accidental errors produced by

the total station, and greatly improve

the precision of the data

This system can also trigger alarms

sent by SMS or e-mail if predetermined

thresholds are exceeded.

System Limitations

References

RRTSs are nearly always installed

inside the area of influence of the work

site where settlements are expected.

The position of the total station and the

associated prisms are computed based

on reference prisms located outside the

area

The adequacy of the whole system

is based on the quality of the reference

prisms. They need to be:

• Well distributed to guarantee the ro-

bustness of the system

• Located in a stable zone outside the

area of influence

• Located at a distance which depends

on the precision required

Range

Depending on the type of total station

used, the range of the distance meter

is limited (typically 60-70m). To

guarantee a good reflection quality of

the laser beam the angle of incidence

on the measured surface is also a

criterion that influences the range of

the measured RSP. Finally the surface

Figure 1. Example of Reflectorless Robotic Total Station (RRTS) installation able to

measure RSPs and prisms.