Geotechnical News September 2011

31

WASTE GEOTECHNICS

volumes of MSW that was distributed

among several locations in each city.

For example, there were over 1,000

MSW dumping locations distributed in

the city of Beijing. Most of the simple

dumps have been closed, but controlled

closure measures have not always been

followed.

First-generation Controlled

Landfills

After the first

Technical Standard for

Sanitary Landfill of MSW

was issued

and put into action in 1988, landfill

technology and practice in China shifted

from simple dumping to controlled

landfilling. In the 1990s, so-called first-

generation controlled landfills were built

in many cities around China. During this

period, there were over 800 landfills,

about 45% of which were designed as

controlled landfills. The first-generation

of controlled landfills made use of

vertical barriers and toe drains for

leachate control. Most landfills were

located in a valley or canyon. The

low permeability bedrock generally

formed the shape of a “dustpan” with an

opening downstream from the landfill.

Vertical barriers, extending to the

underlying fresh bedrock, were installed

at the downstream opening. The vertical

barriers and the bedrock were expected

to form a closed barrier system against

the leachate transport to the surrounding

environment. The vertical barriers

commonly used in China consisted

of a plastic concrete cutoff wall in

the soil deposit and/or grout curtain

in the weathered rock. There is still

uncertainty and debate regarding the

long-term performance of this type of

vertical barrier. There are variations

in the geology and barrier design that

need to be taken into consideration.

Toe drains have been used for leachate

drainage at the first-generation

controlled landfills. The toe drains

were usually installed at the retaining

dam downstream of the landfill. Field

observations have shown that there can

be serious clogging problems for the toe

drains after the landfills have been in

operation for a while. The clogging of

toe drains combined with poor surface

water management has resulted in the

continual accumulation of leachate, and

hence, a high leachate mound within the

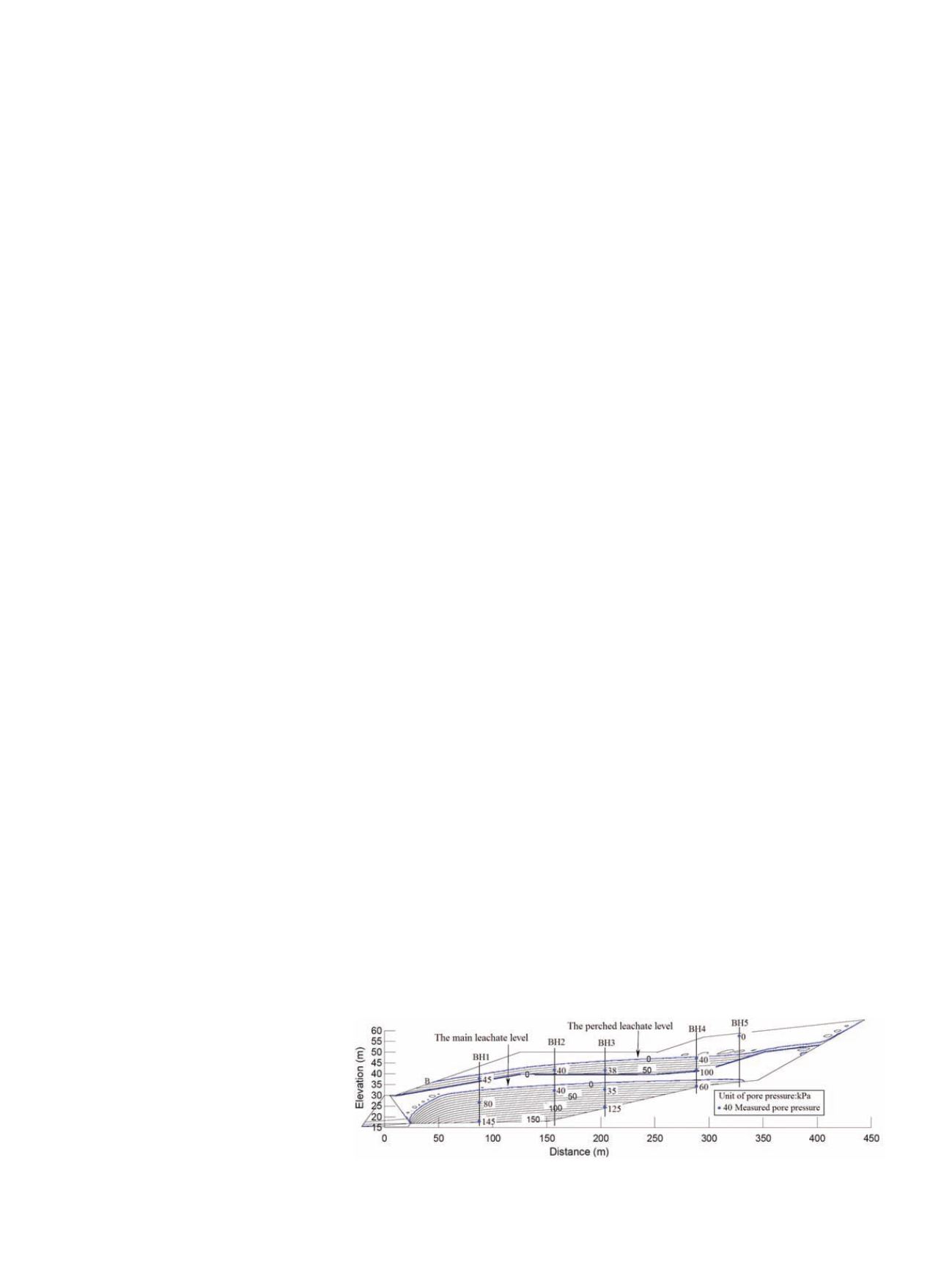

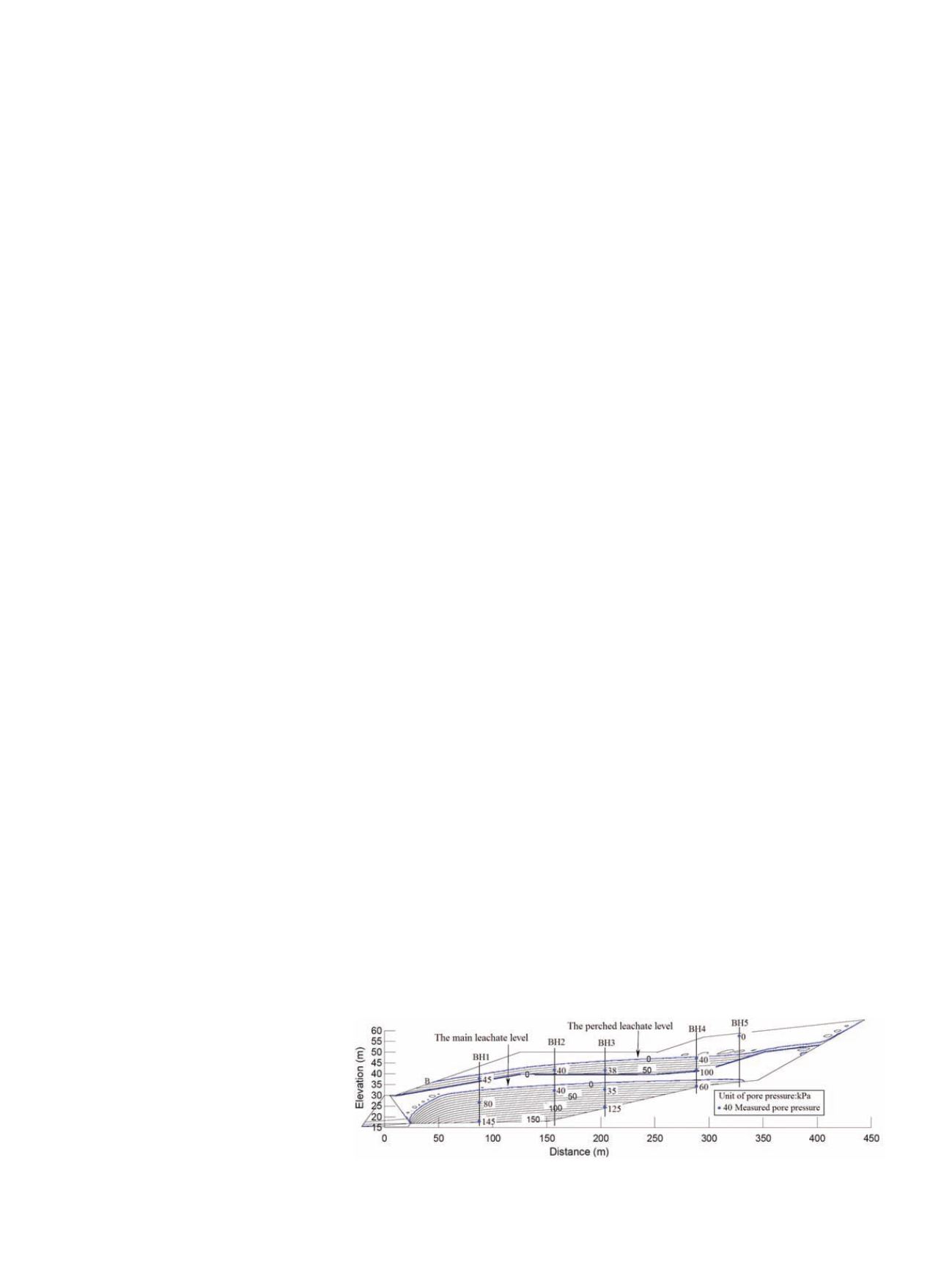

landfill. Figure 3 shows the distribution

of a leachate mound within the Suzhou

landfill. The plot of the leachate mound

was deduced from field measurements

of pore pressures and unsaturated-

saturated seepage modeling (Chen and

Zhan, 2007). The maximum height

of the leachate mound in the landfill

bottom is 15 m. A substantial perched

leachate mound was also observed on

the intermediate soil cover.

Control of landfill gas emission

was not widely implemented at first-

generation controlled landfills. Few

of the landfills were equipped to gen-

erate energy or recover landfill gas.

Additionally, many landfills had poor

management practices: landfill opera-

tions generally involved poor planning

of waste placement, poor compaction

of waste piles, use of soils for daily

and temporary covers, and poor man-

agement of surface water. As a result,

the daily leachate production at the

first-generation controlled landfills was

commonly more than 30% of the daily

dumping mass of wastes, which was

much greater than expected. The high

leachate production tended to over-

whelm the leachate storage pond and

treatment system. Stated another way,

the first-generation controlled landfills

operated at a low level. There is a lack

of detailed data, but it is quite clear that

some landfills have had an adverse en-

vironmental impact.

Second-generation Controlled

Landfills

In the 2000s, many of the first-

generation landfills had reached their

service design capacity. New and

expanded landfills are being built in

many cities in accordance with the

revised regulation and standards,

including the

Technical Standard for

Sanitary Landfill of MSW

(CJJ17-

2001, CJJ17-2004) and

Pollution

Control Standard for MSW Landfills

(GB 16889-1997, GB 16889-1997-

2008). The new landfills are called

second-generation controlled landfills.

The functionality of this generation

of landfills is quite similar to that of

modern landfills in North America.

A composite liner system, consisting

of a basal sealing liner and a leachate

drainage and collection system

(LDCS), is commonly used for leachate

control. China’s landfill technology and

capacity has increased significantly to

meet the service demand associated

with

rapidly

increasing

waste

generation. The daily filling capacity

for landfills in large cities is commonly

over 3,000 ton/day with a designed

service period of at least 20 years. For

example, the Laogang landfill site in

Shanghai has a daily capacity of 5,000

tons with an estimated service period of

45 years. With an increase in capacity,

the

number of controlled landfills in

China decreased significantly from 571

to 366 from 2001 to 2007.

Many second-generation controlled

landfills have taken measures to re-

duce landfill gas emission. Landfill

gas drainage and/or its collection have

been implemented at most controlled

landfills. Over 20 landfills are equipped

with gas recovery facilities, and the total

generation of electric power is about 50

MW. Several landfills have succeeded

in the application of projects adhering

to the Clean Development Mechanism

(CDM) under the United Nation Frame-

work Convention on Climate Change.

Landfill management practices have

also significantly improved. Many land-

fill operators devote considerable ef-

fort to develop waste phasing schemes

and surface water control measures to

separate precipitation from leachate. Al-

Figure 3. Pore pressures measured in the field and distribution of a leachate mound

predicted by numerical simulation.