46

Geotechnical News •March 2015

GROUNDWATER

An unexpected short-duration warm-up and rainfall event

during winter: ice-clogged drains and damage to a building

Robert P. Chapuis

Context

This is the fourth historical case study

on “groundwater” problems that I

have presented in Geotechnical News.

This unusual case concerns a drainage

system for an industrial building with

distinct sewers for sanitary sewage

water and stormwater. The building

had a nearly flat roof, which is quite

common in industrial areas, probably

because it is cost efficient, requires

less material and provides more room

space than a sloped roof. Also, it is

easier to walk on and inspect.

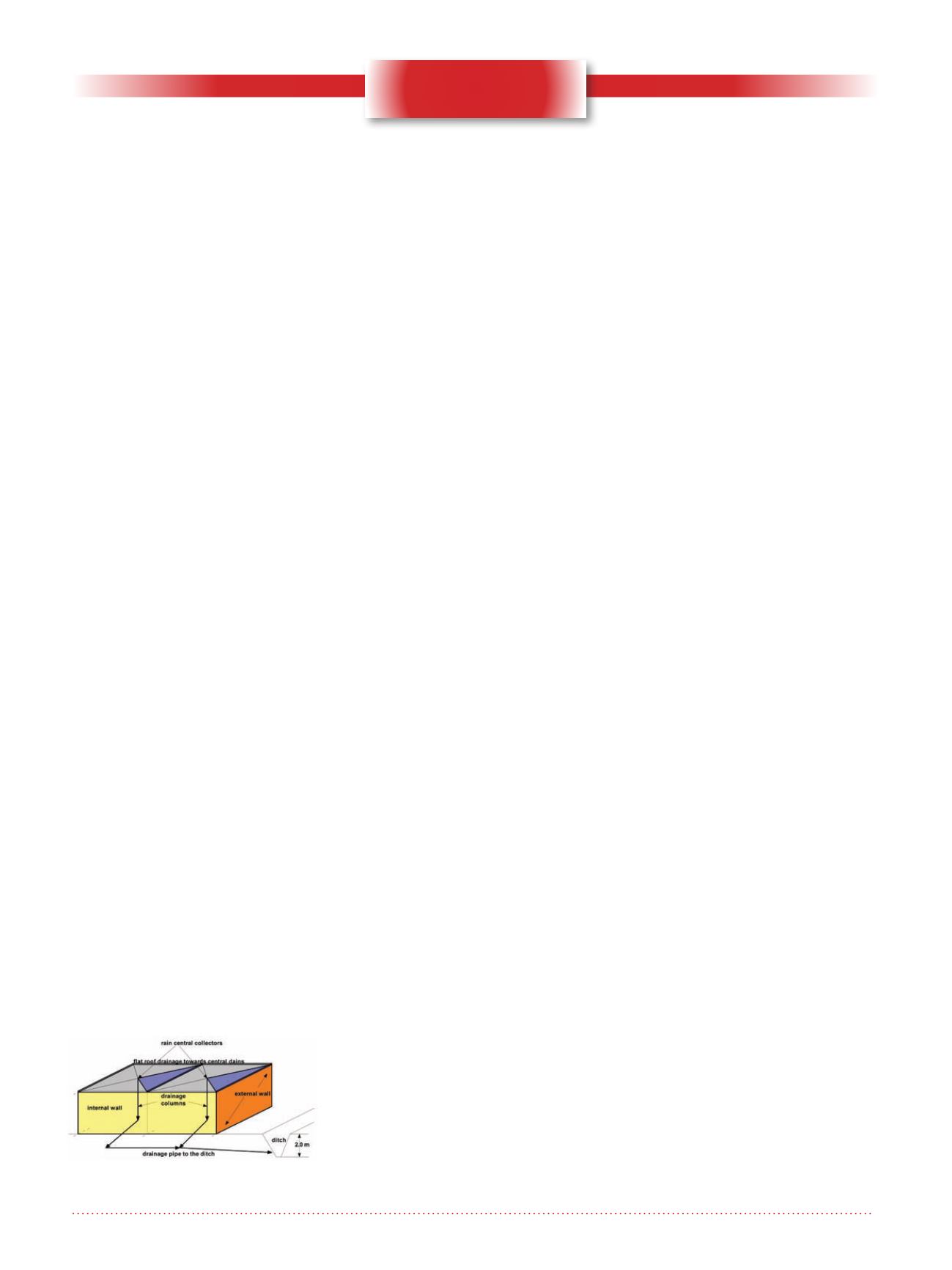

The large roof had several sections,

each with a small slope towards a

central collector, a simple gravity

drainage system which avoids water

ponding. Each drainage column

was located within the heated build-

ing, which avoided the risk of water

freezing and damaging the pipes and

building structure. Each drainage

column discharged rain water and

snowmelt to a sewer pipe, leading the

water towards a ditch about 2 m deep

(Figure 1).

Prior to the event recounted in this

paper, the flat roof was in excellent

condition. There was no water pene-

tration into the underlying decking and

insulation. Each central collector was

protected with a metal screen to avoid

entrance of gravel, airborne debris,

leaves, and wildlife. In addition, the

end of the drain pipe, in the ditch, was

screened to prevent entry and nest-

ing of wildlife, which could cause

clogging. Therefore, clear precautions

had been taken to have a rodent-free

and snake-free building, to avoid pipe

clogging and rodent damage within

the building.

The event

The event which caused damage

occurred in the middle of winter, when

one day, the air temperature rapidly

increased from -15

º

C to a few degrees

above freezing, and stayed above 0ºC

for only 2-3 days. This rapid but short

warm-up also brought a few centi-

metres of rain, which caused some

additional snow to melt, clearly visible

in the parking lot. However, nobody

paid attention to what was happening

on the flat roof, which had to drain

several cubic meters of rain and melt-

ing snow.

Inside the building, some time has

passed before it was realized that

water had started spurting from the

joints of the vertical drainage columns,

damaging the building and some

stored goods. The spurting water was

clear, cold and under pressure. An

employee climbed onto the roof and

saw standing water in each flat divi-

sion. The vertical drainage columns

were made with plastic pipe sec-

tions simply fitting together (no glue,

no welding): this system was quite

frequently used for vertical drainage

pipes, but it cannot resist water under

pressure.

Investigation and repair

The investigation for this case was

quite simple. There were pools of

standing water on the roof. Water was

supposed to fall freely through the

vertical drainage columns but this was

not the case. Water could flow from

the roof into the vertical drainage col-

umns where it was under pressure, but

it was squirting out by the pipe joints

inside the building. Therefore, there

must have been some clogging in the

underground drainage system.

An inspection of the drain pipe outlet

in the ditch revealed that the pipe was

blocked by a long cylinder of ice. Dur-

ing winter, a small amount of water

had started to freeze close to the pipe

outlet, and additional water reaching

this ice became gradually frozen, due

to cold air entering the drain pipe.

As a result, an ice “dam”, made with

a long ice plug, was formed which

blocked water behind it. In previous

winters, there has been no sudden

warm-up, and slow melting of the ice

plug allowed water to reach the ditch.

Unfortunately, during the rapid but

short warm-up in this case, the under-

ground ice plug, insulated from the

warm outside air, did not melt, which

caused damage inside the building.

In order to counteract the possibly

dangerous consequences of a fast

warm-up, a few meters of electric

de-icing (heating) cable were subse-

quently installed in the end part of the

drain pipe, near its outlet. The cable

was similar to those used for keeping

rain gutters free of ice during cold

weather. The heating cable operation

was controlled by a device which

checked the temperature around the

cable, in order to prevent future freez-

ing of water within the drain pipe.

Figure 1. Sketch of the building and

its stormwater drainage system.