Geotechnical News • June 2016

35

THE GROUT LINE

of weeks of laboratory testing, and

full-scale mix testing using the same

mixer which would eventually be

used to the main works, two grout mix

designs were eventually selected.

a. for the primary holes, a slag-based

cement using 32 µ material, with

the addition of a super-plasticiser,

and with a gelling agent to assist in

retaining grout in situ despite the

significant hydraulic head across

the grout curtain. In addition, the

mix was tested with an accelerator

in case significant voids or fissures

were encountered which could

lead to the grout being washed

away and into the river down-

stream of the dam.

b. For the secondary and tertiary

holes, a slag based cement using

12 µ material, with the addition

of a super-plasticiser and gelling

agent

In order to avoid premature blockage

of the extremely fine fissures, it was

necessary that the rheological prop-

erties of the grout remain constant,

well controlled, and well understood

throughout the injection, and consider-

able care was taken in ensuring that

the gel times of the two mixes would

allow injection of the full target vol-

ume when using the GIN technique. A

minimum gel time of not less than 2.5

hours was established.

The GIN value was carefully selected

to reflect the average absorption per

linear metre experience during the

2003 works, the designers’ require-

Hydraulic Testing

Preliminary results

Borehole VH04

Interval

Test

Event

P

i

P

END ∆

P

∆

P Flow

Lugeon h "s"

(2)

T

K

T

K

Top Bottom Length

Rate

Hl

Steady

Units

[m]

[m]

[m]

[kPa]

[kPa]

[kPa]

[kPa] [ml/min] [sec]

[sec]

[l/m/min] [mbgl]

m2/s

m/s

m2/s

m/s

VH04‐i2

37.80

49.00

11.20 Hl

403.63 522.44

118.81 1.19

1.126 1800 1800

0.8

5.00 1.70E‐06 1.52E‐07

1.43E‐06

1.28E‐07

VH04‐i3

32.80

37.81

5.01 Hl

355.34 632.51

277.17

404 1241 1000

0.29 5.02 1.86E‐07 3.71E‐08

1.78E‐07

3.55E‐08

VH04‐i4

27.80

32.81

5.01 Hl

250.01 636.15

386.14 3.86

59

916 600

0.03 10.86 1.31E‐08 2.62E‐09

***

***

VH04‐i5

25.20

30.21

5.01 Hl

151.06 561.44

410.38 4.10

49 1018 200

0.02 18.39 7.70E‐09 1.54E‐09

***

***

VH04‐i6

20.20

25.21

5.01 Hl

157.97 498.29

340.32 3.40

44 1073 500

0.03 12.79 1.05E‐08 2.10E‐09

***

***

VH04‐i7

16.00

21.01

5.01 Hl

183.41 558.84

375.43 3.75

1127 1127 700

0.13 6.08 7.04E‐08 1.41E‐08

1.40E‐07

2.79E‐08

(1)

Depth along borehole axia

(2)

Head in vertical meters below ground level

P

i

Initial pressure, or best estimate of "static" pressure

[l / min]

2.00E‐06

P

END

Pressure at end of test

[m]

0.048

h s

"static" head, metres below ground level

Sensor P2 above top interval

[m]

1.66

P1

Pressure below bottom packer

P. atm (P2 prior to installation)

[kPa]

105.06

P3

Pressure above top packer

Inclination ( from Horizontal )

[

0

]

78.7

SL

Straight‐line

SSA

Steady‐state approximation

straiht line fit on middle time data, SSA on late

time data, positive skin effects SSA results

Assumed spez. Storativity

Well radius

Straight‐line analysis

Steady‐state

HI: very low transmissivity zone, no straight

line fit possible, SSA on middle to late time data

HI: very low transmissivity zone, no straight

line fit possible, SSA on late time data

Upper packer is inflated in the concrete, HI:

Single packer test, bottom of interval is

uncertain, the borehole was dipped before

the test to 40 mbgl, here the interval is

assumed to be 11.2m. Hl : straight line fit on

late time data, SSA on late time data

Hl: little bypass P1(14.8 kPa), straight line fit

on middle time data, SSA on late time data

HI: very low transmissivity zone, no straight

line fit possible, SSA on late time data

Depth

(1)

Duration

Remarks

approximation

(transient)

(SSA)

(SLA)

Table 1: Preliminary hydraulic testing results from validation boreholes

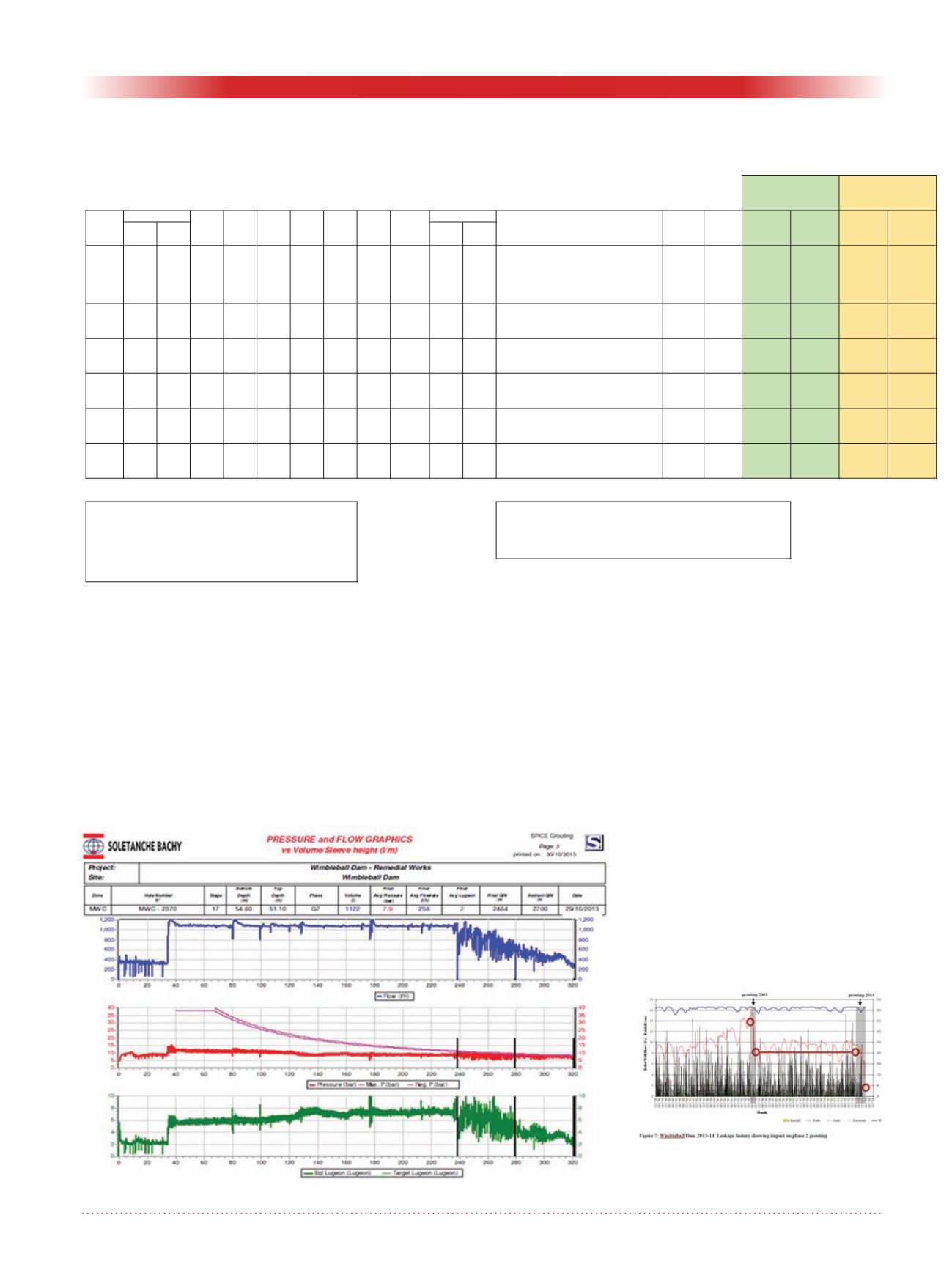

Figure 6. Pressure and flow graphics.

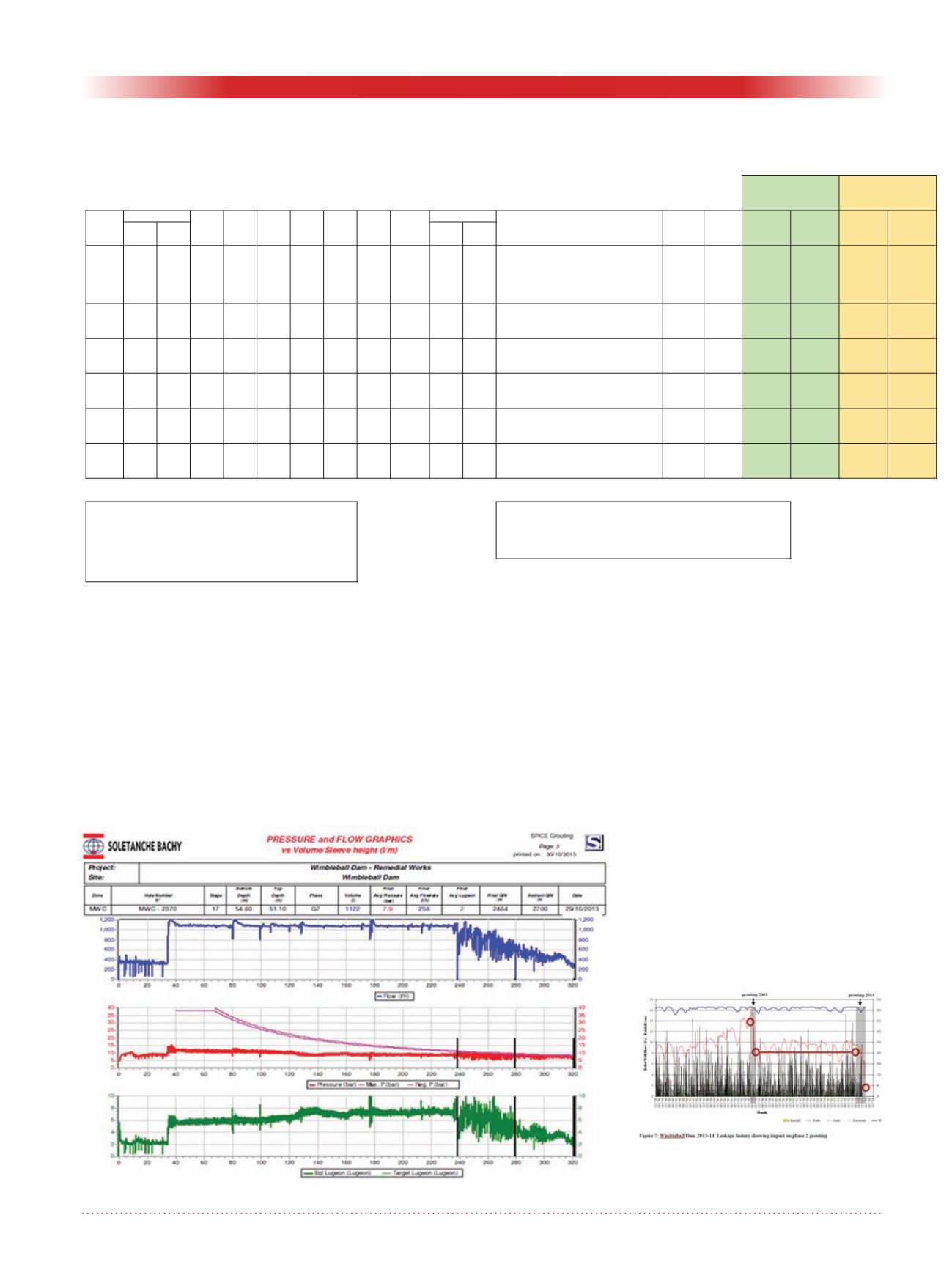

Figure 7. Wimbleball Dam 2013-14:

Leakage history showing impact on

phase 2 grouting.