Geotechnical News • September 2016

25

GEOSYNTHETICS

construction of a new earthfill dam

located immediately downstream of

the original hydraulic fill dam (Hart-

ford and Lou, 1994).

Spillway structure rehabilitation

The original concrete-lined spillway

of the Alouette Dam was built in 1926,

with control gates and an overflow

weir, in order to carry flood water

around the earthfill dam and safely

discharge it below the downstream

toe. The elevation drop between

the spillway crest and the Alouette

River was accommodated by an ogee

structure at the end of the spillway: it

was founded directly on the excavated

ground and incorporated a concrete

cut-off toe wall on all three sides.

Erosion protection was afforded by

submerging the discharge section at

the end of the ogee structure, thereby

inducing a hydraulic jump in the

backwater pool, which acts to dis-

sipate energy from the flow of water

(Carpenter, 1927). Further erosion

protection was afforded by a concrete

slab that extended beyond the toe wall,

and by a transition blanket of riprap

along the rise of the channel through

which discharge over the spillway was

returned to the Alouette River. The

spillway was partially rebuilt in 1955

following flood damage (Brown and

Nielson, 1992), and further improved

in 1961, 1983 and 1985 before under-

going a major rehabilitation in 1992

(see Fig. 1).

The “Alouette Dam – 1992 Spillway

Rehabilitation Project” was under-

taken to accommodate a revision to

the design extreme flood magnitude.

Additionally, it was undertaken to

address some observed deficiencies

that had been identified through engi-

neering inspection, including erosion

and undermining of the spillway foun-

dation, as well as deterioration of the

original concrete. Erosion beneath the

spillway was attributed to no provision

being made, at the time of original

construction, for under-drainage

between the spillway and its founda-

tion. The rehabilitation works included

placing a new spillway gate, replacing

the original portions of the spillway

channel, and constructing a new still-

ing basin. Importantly, the rehabilita-

tion work included filter and drainage

provisions underneath the spillway

channel that were intended to prevent

uplift of the slabs during major floods

due to potential large fluctuations in

water pressure during flood routing.

The safe, long-term operation of the

spillway is governed by the capacity

of the under-drain to collect, depres-

surize and remove any groundwater

that seeps into it from the founda-

tion soil. Further, it must collect and

remove any channel flow that enters

it through the concrete liner during

a period of spillway use. In order to

provide for this design function, the

drainage system must be protected

against ingress of the foundation soil

on which it rests. Accordingly, a filter

was placed between the foundation

soil and drainage layer.

The configuration of the drainage

system differs along the length of the

spillway. Where possible, such as

the spillway invert, granular filters

and drains were used. A total of three

combinations of materials were used

in construction: (i) a granular filter and

granular drain, (ii) a geotextile filter

and granular drain, and (iii) a geo-

textile filter and a geosynthetic drain.

More specifically, a granular filter and

drain was specified in contact with the

base of the spillway channel where the

slope is relatively flat. A combination

of geotextile filter and granular drain

was used on the sloping section of the

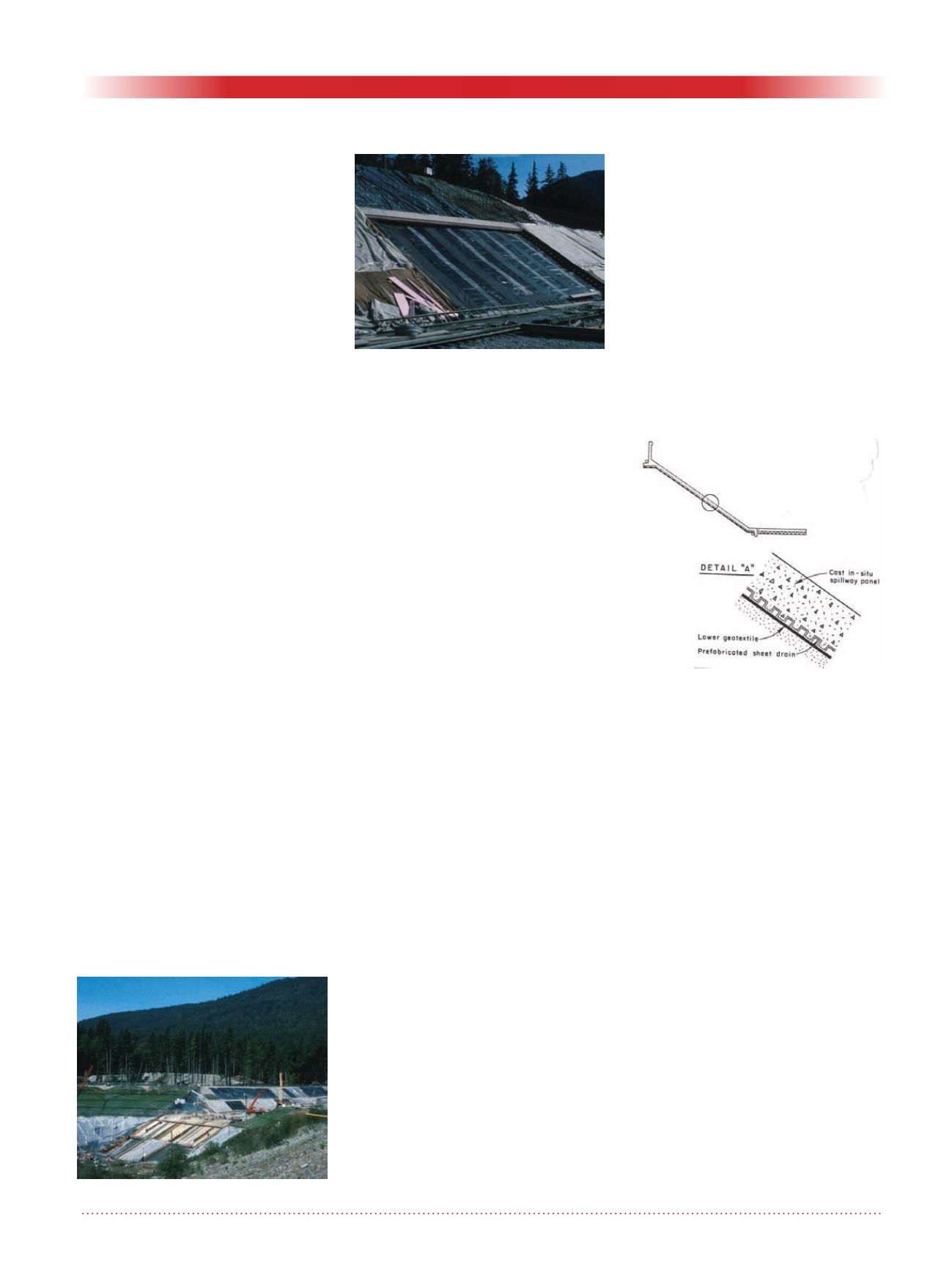

spillway base. On the steeply inclined

sidewalls of the spillway channel,

the specification required a combina-

tion of geotextile filter overlain by a

moulded plastic sheet-drain of single

cuspate construction (see Fig. 2). The

resulting geocomposite filter-drain

was custom-designed and assembled

on site: several off-the-shelf pre-

assembled products were available at

the time, but were deemed unsuitable

for this application. The sidewalls

were excavated at an ngle of approxi-

mately 1.5H:1V over a length of 170

m on one side, and 50 m on the other

side, of the spillway channel. The

combination of geosynthetic filter and

drain was specified for the sidewalls

because it was expected the steep cut

would present a significant chal-

lenge for economic placement, and

satisfactory compaction, of a granular

material filter and drain. Further, there

was concern that heavy rainfall might

Figure 1. General view.

Figure 2. Configuration of the

geotextile filter and sheet drain.

Figure 1b. Inclined sidewall of the

spillway channel.