Geotechnical News • December 2016

27

GEOTECHNICAL INSTRUMENTATION NEWS

Vibrating wire MPBX, despite being

tedious to install properly when com-

pared to other solutions, were chosen

because we would have a single type

for all instruments. This gave us the op-

portunity to greatly reduce cabling and

to facilitate integration into the data-

loggers.

Given the long cabling distances in this

project, using vibrating wire instru-

ments sidesteps the issues of voltage

drops that occur with potentiometer-

based MPBX.

Installation

In this project, the MPBX were in-

stalled directly into the bedrock and

there was very little risk of using an

improper (too soft) grout mix.

Results

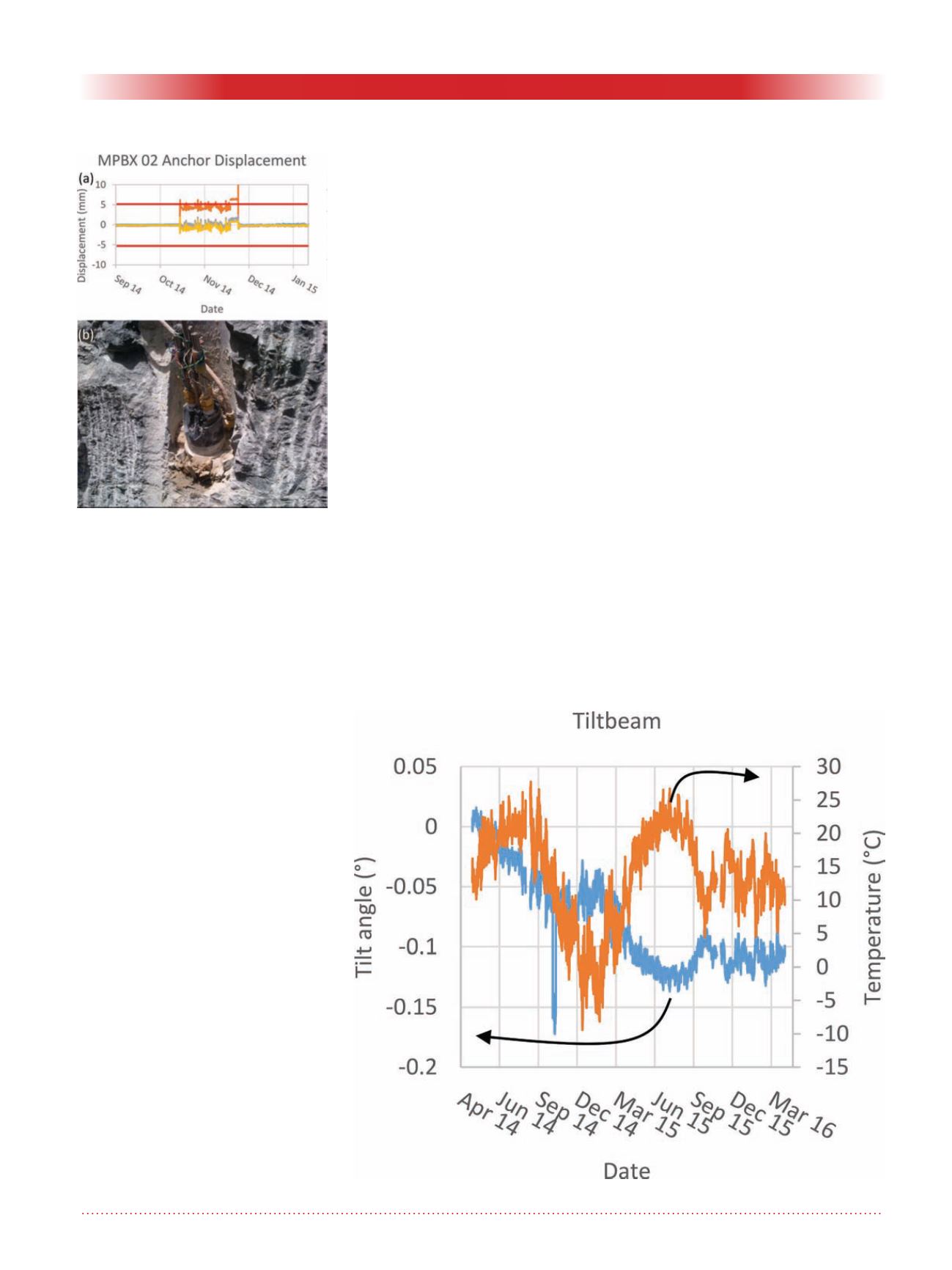

This project showed that confidence in

the instruments and their reliability can

prove critical. Indeed, every MPBX

installed in this project gave nearly-

constant and consistent measurements

over months. In October 2014, the

measured values of one MPBX jumped

to more than 5 mm, above the alarm

threshold (figure 3 (a)). A rapid inves-

tigation found that a worker had exca-

vated just beyond the planned limit and

hit the head of the instrument.

Relying on redundancy and histori-

cal data, the engineers were confident

enough in the instrument and in the re-

dundancy we had implemented to not

immediately stop work despite going

against their internal processes.

Damage to the head occurred on a few

occasions, an example of which is de-

picted in the photograph of figure 3 (b).

It can be seen that, in this case, half the

head of the instrument was torn off.

The simple fact that the instrument was

nearly destroyed shows their vulner-

ability in a demolition and restoration

project.

Recommendations for future use

Performing long term-monitoring to

build confidence in the instrument and

the measurements is strongly recom-

mended whenever possible. This con-

fidence helps the engineers to make the

right decision when unexpected jumps

or breaks in the data occur.

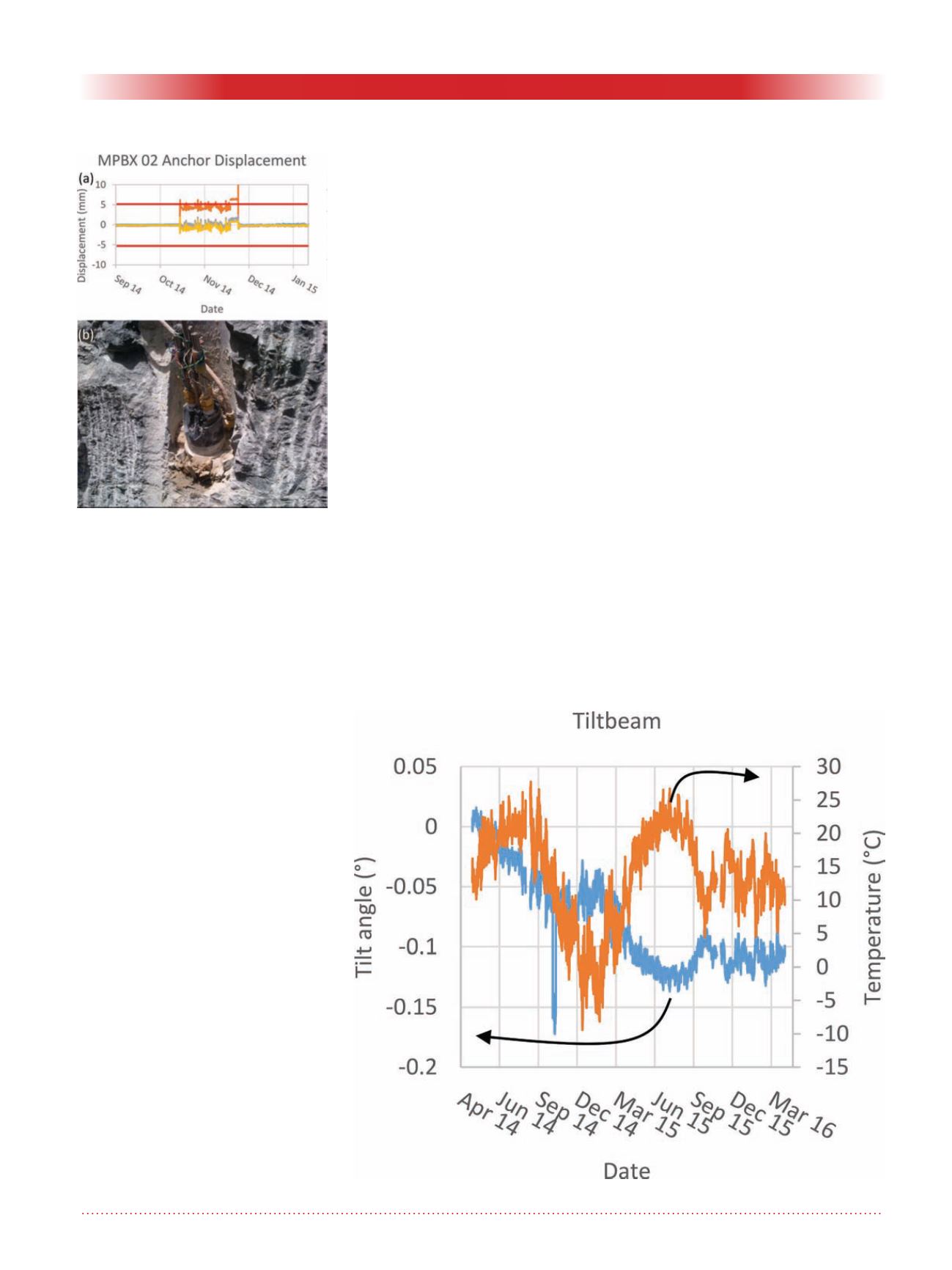

Tiltbeams

Purpose and description of

instruments

Vulnerable walls were monitored with

vibrating wire tiltbeams (Geokon mod-

el 6350). Though tiltmeters are com-

monly used in structural health moni-

toring, tiltbeams were selected because

they were to be installed on masonry

walls which can flex due to their mortar

joints. Using long (2 m) tiltbeams av-

erages out localized tilts and provides

a better image of the behaviour of the

walls.

Vibrating wire tiltbeams were selected

over electrolytic or MEMS sensors,

two other common types of tiltmeters.

First, they are less sensitive to tempera-

ture effects than electrolytic tiltmeters.

Second, integration is facilitated by

using a single signal types and by re-

quiring very little power over long dis-

tances.

Sources of inaccuracy

Temperature-induced errors are the

main sources of inaccuracy in this type

of instrument. First, temperature affect

Figure 3. (a) Anchor displacement

of a damaged MPBX

(b) Photograph of the head of a

damaged MPBX).

Figure 4. Tilt angle over time (blue) and temperature (orange).