Geotechnical News • March 2018

29

Geological engineering -

“

Smart

”

ground support:

Continuous strain monitoring using fiber optics

Nicholas Vlachopoulos and Bradley Forbes

The need for continuous strain

sensing of ground support

elements

A rising demand for underground

transportation and resource manage-

ment has led to the development of

many more subterranean projects

(deep foundations, tunnels, utility

corridors etc.) which are constructed

at larger scales, over greater distances,

increased depths, and within proxim-

ity to sensitive urban environments

(i.e. reduced tolerances with respect to

adjacent infrastructure). For such proj-

ects, engineering design of support is

primarily based on the stress and strain

that are developing within the support

structures as a result of the surround-

ing ground conditions. These ground

loads are distributed continuously and

spatially and as such, an improved

understanding of the continuous strain

profile would provide better insight

into the true behaviour of such support

elements. Research currently being

conducted at the Royal Military Col-

lege of Canada focuses on such micro-

scale geomechanical mechanisms and

interactions with a view to determin-

ing the overall design implications for

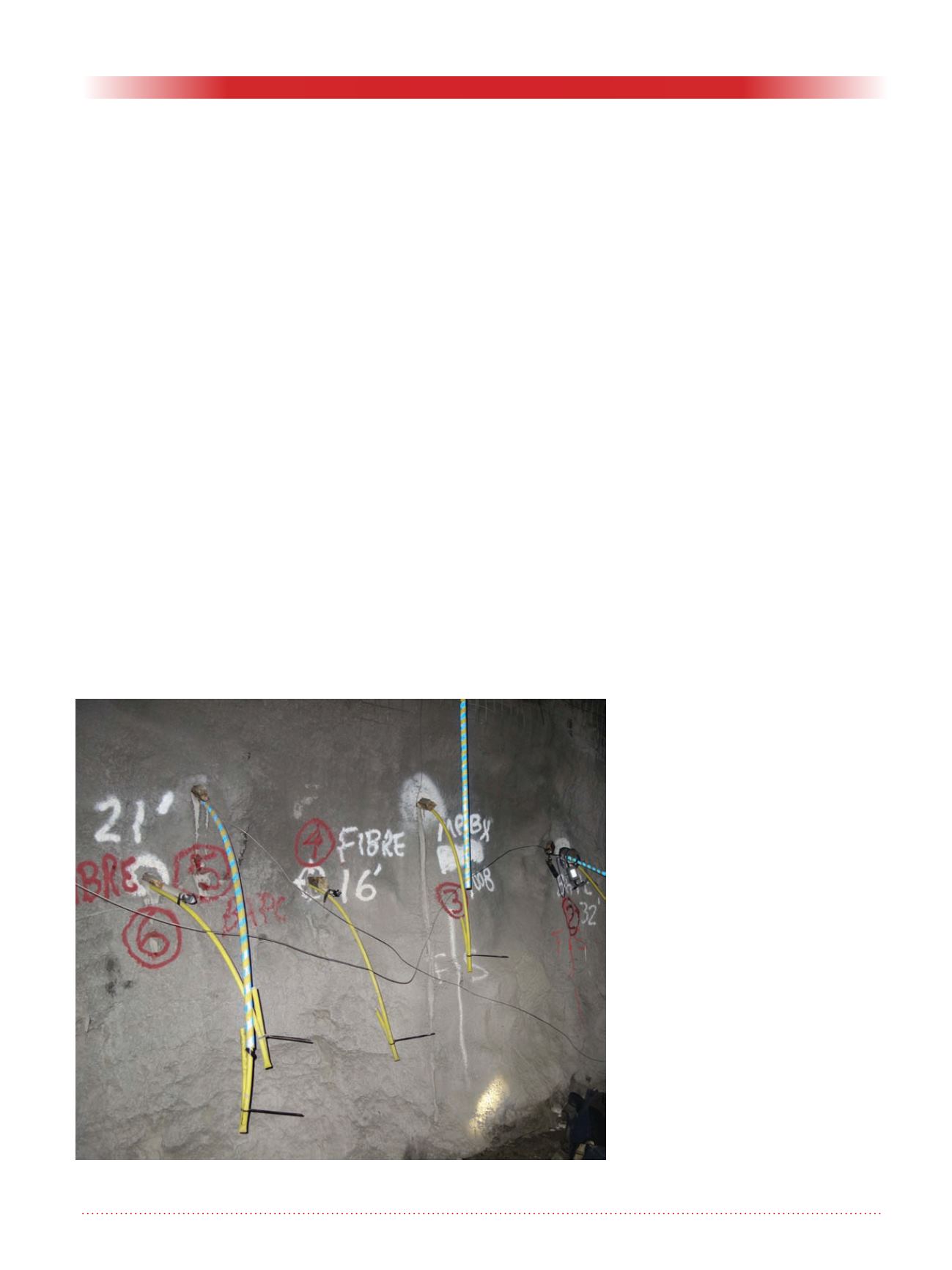

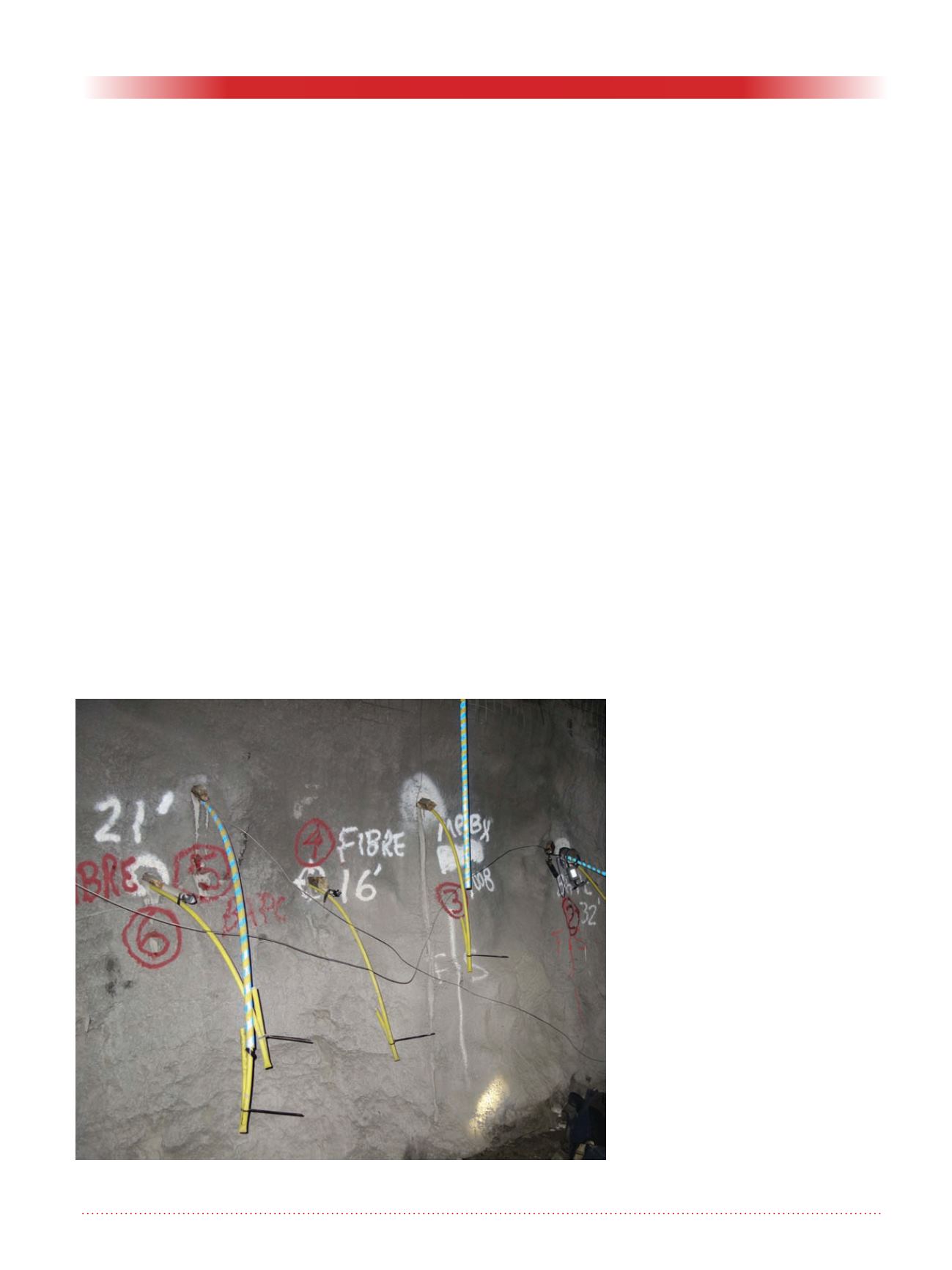

full-scale (Figure 1) support design for

tunnels (for example).

The use of fiber optics within the

Geotechnical / Geological Engineering

field is not a new concept. There are

multiple projects that have utilized a

particular type of fiber optic technol-

ogy in the past, ranging from their use

to monitor the construction and perfor-

mance of embankments, tunnels, piles,

mining operations and other geotech-

nical works. It is important to note

that not all fiber optic technologies are

similar as each type has their unique

strengths and limitations. Historically,

monitoring of such ground support

members has been limited to electrical

and mechanical techniques (e.g. foil-

resistive strain gauges, inclinometers,

linear variable displacement transduc-

ers). Such techniques provide discrete

measurement points, implying that

many sensors are required to obtain a

full strain profile along the length of

the support element.

These techniques provide a limited

spatial resolution along the element,

making such methods prone to mis-

interpretation, underestimation, and

possibly omission of support response.

For example, it not uncommon to

observe a ‘failed’ rock bolt that has

been subjected to both axial loads

as well as bending (i.e. transverse

loading(s))

Optical fiber technology,

specimen preparation and

methodology developed

An optical frequency domain reflec-

tometry (OFDR) technology using

low cost single mode optical fiber was

investigated as a potential distributed

strain monitoring technique for ground

support members. What makes this

OFDR technology particularly attrac-

tive for monitoring the aforementioned

support elements is the capability to

monitor strain with a spatial resolution

of 0.65 mm along the length of the

optical fiber sensor. As well, the opera-

tional accuracy is quite acceptable

(better than +/- 10 microstrain).

COMPUTING IN GEOTECHNICAL ENGINEERING

From the GS Board

Figure 1. Macroscale testing: fiber optics installed in an active mine within

Northern Ontario.