30

Geotechnical News • March 2018

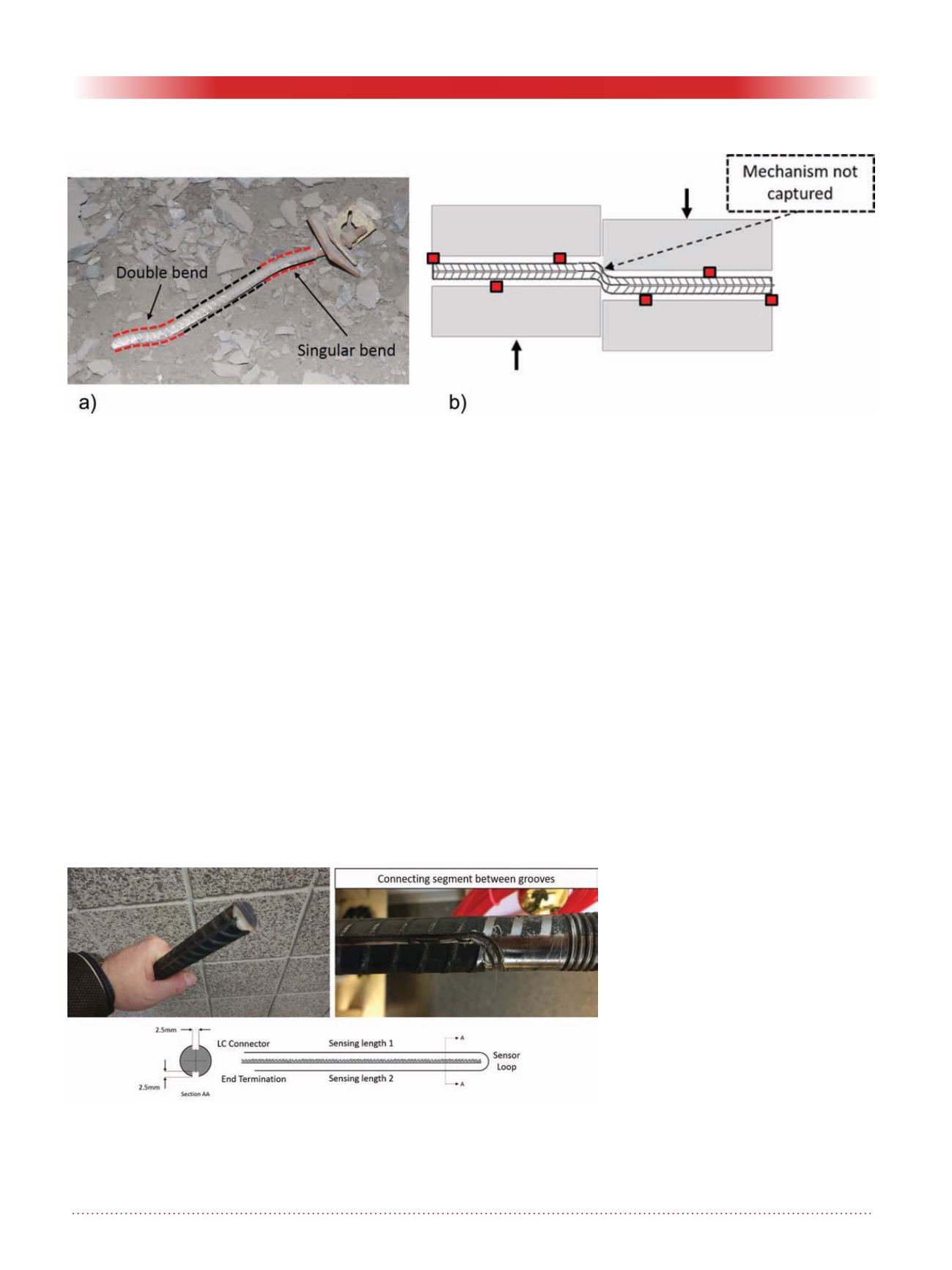

In order to test the technology and

methodology developed, No. 6 Grade

60 rebars were prepared by instru-

menting them with a fiber optic. Steel

bars were modified with 2.5 mm

by 2.5 mm diametrically opposing

grooves as shown in Figure 3.

Performance? Lessons learned?

Selected laboratory testing and

results

To date, many configurations of test-

ing that include axial, bending, and

shear testing have been conducted

utilizing multiple support elements.

These support elements were tested as

unique specimens as well as grouted

within concrete (rock) samples. The

support tested in the laboratory to date

includes: Rebar (rock bolts), D-bolts,

Cable bolts, Spiles and, Forepoles.

Each sample preparation has its own

unique challenges in terms of fitting

the fiber optics in conjunction with a

particular support element. In Figure

4 below, one can see selected results

from the laboratory testing that has

been conducted as part of this line

of research. Figure 4a depicts results

from an axial pullout test while Figure

4b depicts results from a 2-way shear

test.

Field trials

As with any technology of this nature,

it is encouraging to obtain excellent

results within the controlled environ-

ment of the laboratory. The question

now becomes how this technology can

be employed in the harsh conditions

associated with the field while limit-

ing its impact on operations. To date,

multiple successful field experiments

have been conducted at 3 separate

locations around the world. The

authors are also in contact with other

interested global parties who have

shown an interest in employing such a

technique within their operations.

Below (Figure 5) are relevant photos

from the in-situ installation of the

fiber optic technology within support

elements that were designed by the

authors. The data amassed in the field

to date is of excellent quality, how-

ever, at the time of publication these

results had not been authorized for

release. None-the-less, it is extremely

encouraging that the technology devel-

oped and tested at RMC is functioning

as expected within the austere field

site conditions with no real interrup-

tion to tunnelling or mining opera-

tions. It should also be noted that a

unique fiber optic instrumentation

solution must be determined for each

type of ground support element; this

is a non-trivial undertaking due to the

unique requirements and installation

procedures associated with each type

of support and site.

COMPUTING IN GEOTECHNICAL ENGINEERING

From the GS Board

Figure 3. Photos and schematic depicting the grooves that were created

during specimen peparation and the outfitting of the optical fiber with details

of optical fiber groove; fiber was looped around one end of the rebar

specimen providing continuous strain monitoring along two sides of the

sample.

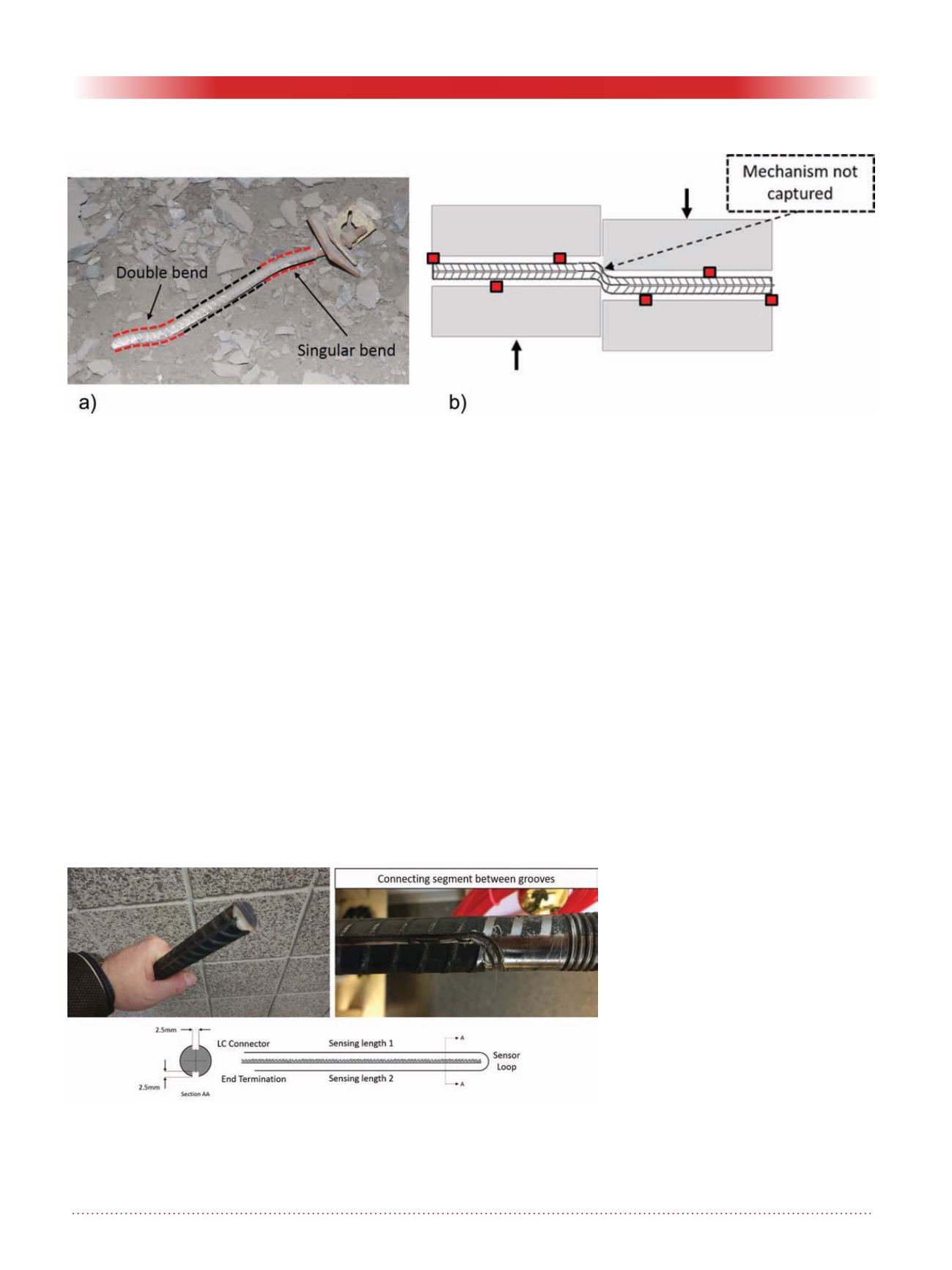

Figure 2. a) Permanently deformed bolt from an active mine site that indicates that the bolt has undergone lateral

deformation and b) Deformed rebar element with sensors (red locations) that are too sparsely arranged in order to

capture the local phenomenon.