44

Geotechnical News • March 2018

THE GROUT LINE

distribution etc.) as well as dewa-

tering and electrical systems

• Security situation in Northern Iraqi

limits the movement of the grout-

ing staff to the site and within the

site. Increases difficulty to recruit

technical staff for the engineer and

contractor.

• Complicated logistics to move

equipment, tools, consumables and

supplies to project site.

• Procurement of materials, tools

and equipment is difficult due to

current made to order European

approach.

• Change in the control of the area

from the Kurdistan region to

the central government of Iraq

impacted the local work force with

some workers not being able to

cross the check points/border to

reach the site

The need to upgrade the legacy grout-

ing systems to meet the demanding

production needs while concurrently

drilling and grouting holes presented

a significant amount of challenges at

the beginning of the project. Approxi-

mately 1950 holes were planned to be

drilled and grouted to establish a sin-

gle line grout curtain across the entire

3.4 km of the dam. The 1950 holes

account to approximately 250,000 m

of drilling and grouting. Of the 1950

planned holes, about 500 were on the

crest and the remaining were in the

grouting gallery. The depths of the

holes varied between 50m and 150m

with an average depth of 100 m.

The magnitude of the grouting effort

required special infrastructure includ-

ing:

• Construction of 3 grout mixing

plants

• Installation of grouting lines and

electrical cables

• Procurement of nine new drill rigs

• Construction of new electrical, ven-

tilation, communication/internet

and water/wastewater systems

• Procurement and setup of 20 BGUs

and ancillary equipment

• Construction of six new office

buildings and a new repair-mainte-

nance shop

• Construction of a secure base

camp facility to provide living and

working accommodations for the

approximately 1000 people on site

To meet the schedule, drilling and

grouting has been performed 24 hours

per day six days per week. To direct,

control and monitor this large round

the clock operation the Owner speci-

fied state-of-art technology includ-

ing advanced communication and

computer-based monitoring systems,

equipment, grout mixes, drilling and

grouting methodologies.

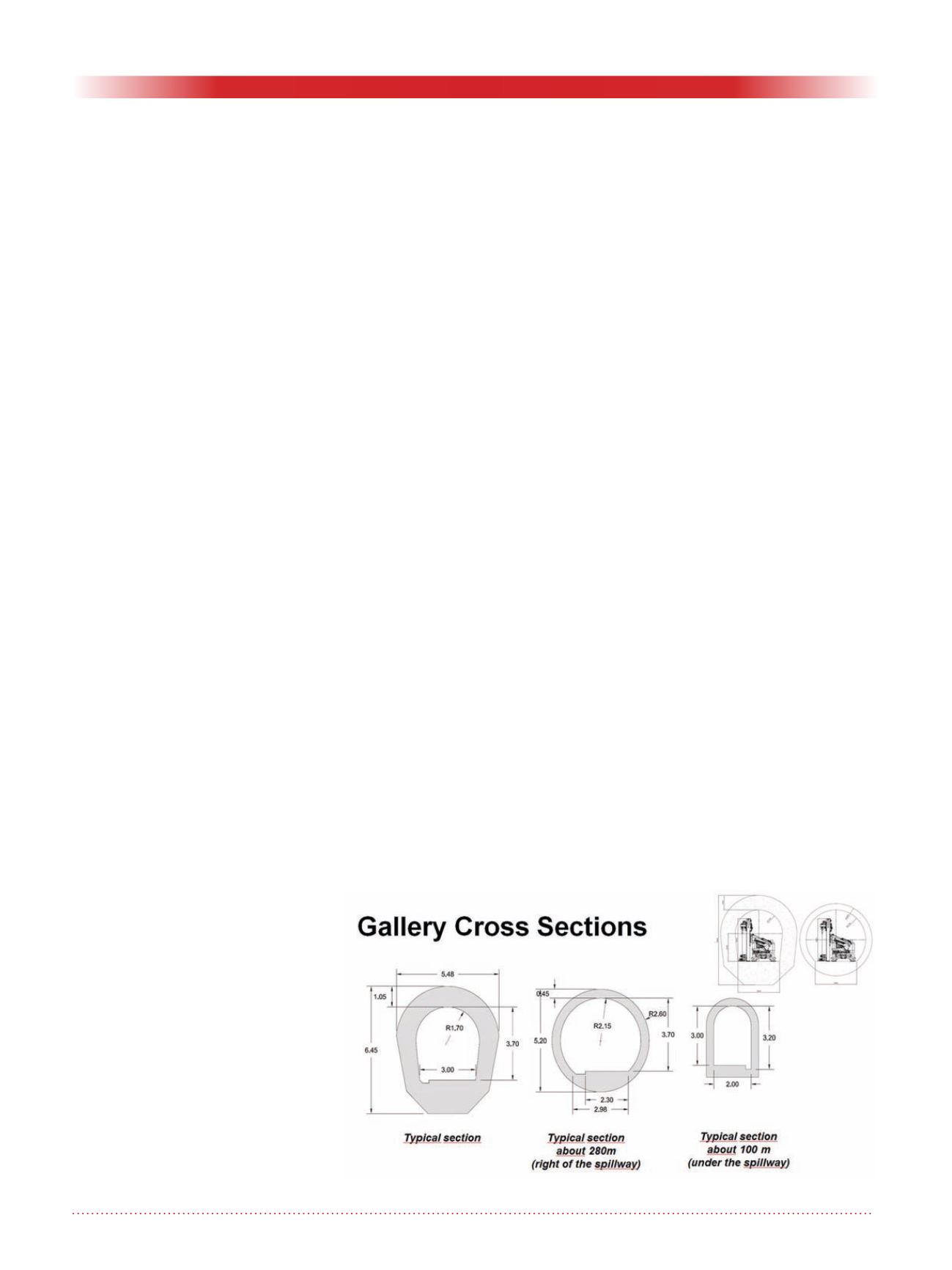

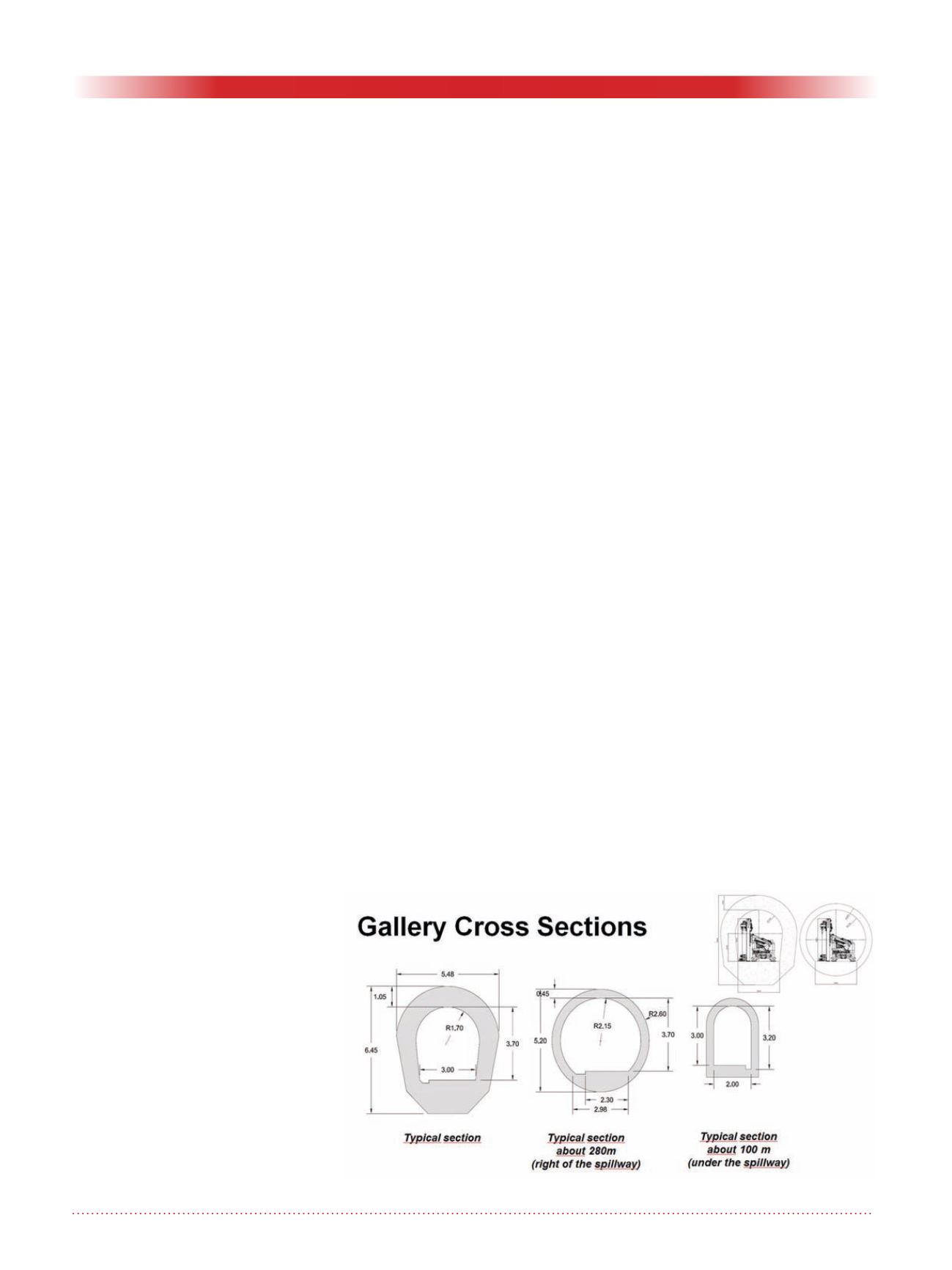

Grouting gallery configuration

The configuration of grouting gal-

lery cross section and profile across

the length of the gallery varies and is

shown in the schematic below (Fig-

ures 4 and 5).

The steep slopes (up to 41%) and

configuration of the gallery cross

section posed a significant challenge

in terms of equipment configuration

and maneuvering requirements. The

grouting units (pumps and dispensing

hoppers) were designed to fit within

the limited space. Customized drill

rigs that can fit within the gallery and

with all terrain capabilities to travel up

and down the slopes were designed for

the job.

Infrastructure upgrade

The infrastructure in the gallery that

was in-place at the beginning of this

task dated from the construction of

the dam. The legacy infrastructure

needed to be replaced in its entirety.

The infrastructure upgrade included

new electrical, water/wastewater,

grout conveyance, grout mixing

plants, communication/internet, light-

ing, ventilation, and concrete delivery

installations (Figures 6 and 7). Details

of the systems are as follows:

• Electrical: Upgrade included

removal of over 3000 m of old

cables and installation of new

cables (170,000 m), cable trays,

transformers and generators to

supply power for the gallery and

crest of the dam.

• Water/wastewater: Over 4500 m of

new pipelines were installed (and

2000 m relocated) to carry fresh

water/wastewater in and out of the

gallery. New submersible pumps

to circulate fresh water through the

3.4 km dam were installed. This

upgrade also included installation

of new sump pumps that carry the

wastewater from the sumps to the

siltation tanks outside the gallery.

• Grout mixing plants: Three per-

manent grout mixing plants that

operate on weight-based batching,

were constructed and positioned

across the length of the dam to

Figure 4. Grouting gallery cross Sections.