Geotechnical News • September 2018

33

THE GROUT LINE

The final mix had a UCS of 9,000 PSI

at 28 days.

The custom mix design resulted in sig-

nificant savings as compared to using

pre-confectioned grout mixes.

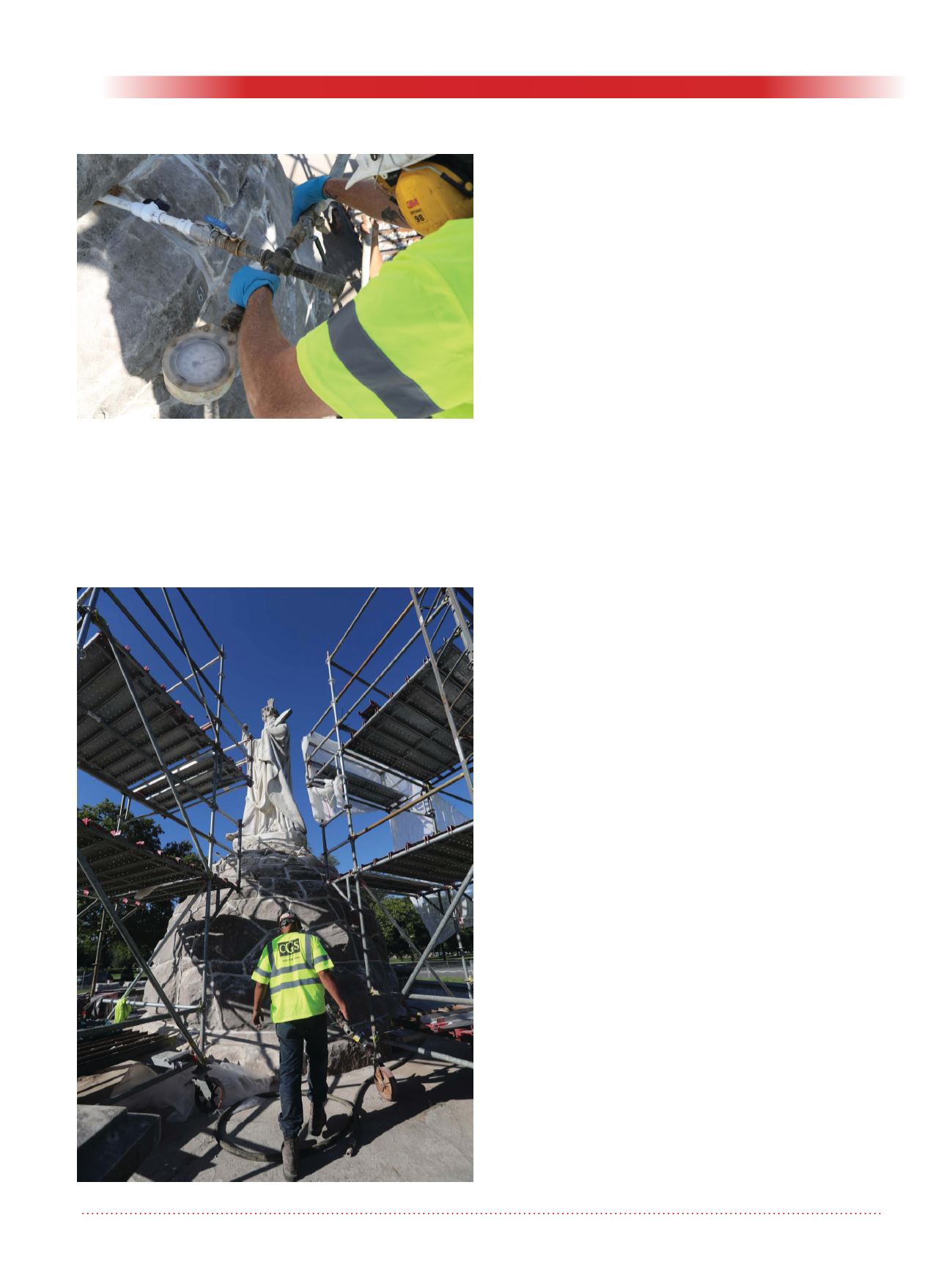

Mixing and

injecting the

grout

The grout mix

was prepared

and injected with

a ChemGrout

CG-600 Colloi-

dal Mixing Grout

Plant. The plant’s

13-cubic-foot

colloidal mixer

and agitation

tank and positive

displacement

piston pump

allowed workers to mix material and

inject at the pre-existing points. A

telehandler was used to deliver cement

pallets to the CG-600 to keep the grout

flowing. Much like concrete, the grout

had to be injected

immediately after

it was mixed.

A total of 460

cubic feet of

grout was

prepared and

injected into the

fountain.

Drilling or cut-

ting through

the granite and

marble was not

permitted, so

finding suitable

existing open-

ings for injection

ports was key. In

those areas with

smaller holes, the

team altered the

mix design, used

smaller diameter

injection ports,

and adjusted the

flow to achieve

adequate cover-

age with the

lower strength

mix. It was also important to consult

with the owner and design team to

make sure this revised approach was

acceptable to support the restoration

effort. The more flowable mix was

generally 1-94 lbs of cement, 5 gallons

of water, water reducing and flow

enhancement admixtures, as needed.

The injection locations were pre-

determined; however, there were areas

such as the granite blocks from the top

row of stairs that had to be temporar-

ily removed to accommodate injection

ports.

The crew had to stay aware of chang-

ing conditions and respond as needed.

This meant observing the joint for

moisture and watching for unwanted

structural movement. The finished

joints were then plugged with oakum,

burlap, and a stick.

The historic nature of the fountain

required the grouting contractor to

exercise extreme caution to prevent

damage. The hardest thing was to use

the PVC pipe and not get the primer or

glue on the statue.

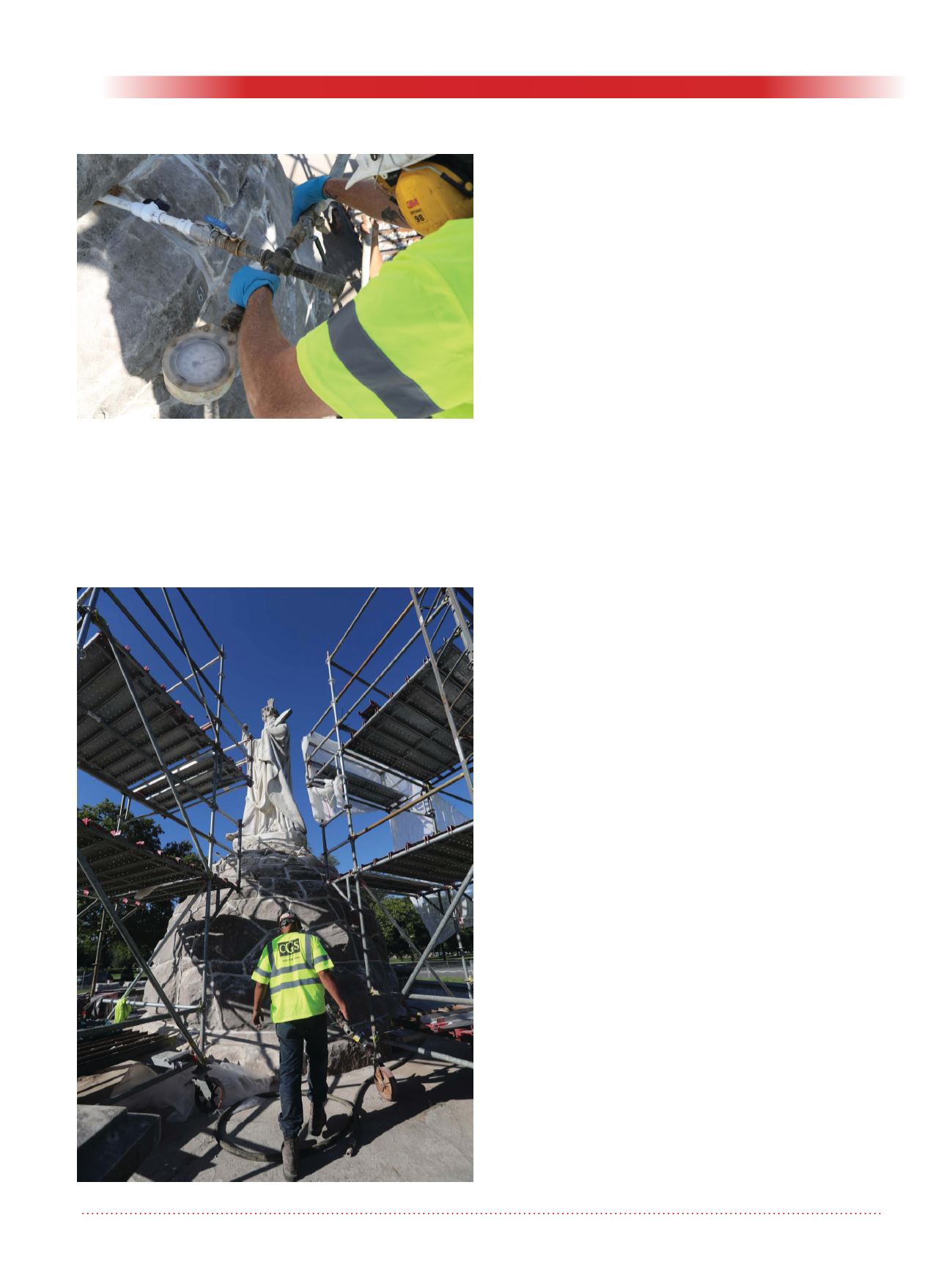

Two weeks to correct a 141-

year old problem

Despite the complexity of the process,

the grouting work was completed on

schedule in two weeks during August,

October, and November of 2016 with

logistical challenges. Perhaps even

more fascinating is the fact that the

grouting helped to correct problems

that unfolded over 141 years in less

than 14 days. All parties are in agree-

ment when it comes to hoping that the

City of Philadelphia will not be issu-

ing another RFP until at least 2158!

As usual I conclude with the same

request, asking you to send me your

grouting comments or grouting stories

or case histories. My coordinates

remain:

Paolo Gazzarrini,

,

or

Ciao! Cheers!

Grout Fairmount Fountain.

Grout Fairmount Fountain.