28

Geotechnical News • September 2018

WASTE GEOTECHNICS

tailings initially. This and the difficulty

of recovering water from the pit, mean

that the tailings may remain flooded

and under-consolidated, rapidly filling

the pit, mainly with water. This is

partially overcome by thickening the

coal tailings prior to in-pit disposal,

although coal mineral-rich coal tail-

ings have proven difficult to thicken.

A number of newer coal projects in

Eastern Australia has adopted belt

press filtering of the tailings, and the

mixing of the output with coarse reject

for disposal within the spoil piles.

However, Smectite-rich coal tailings

have proved difficult to filter, resulting

in a wet mixture of tailings and coarse

reject, and hence a wet co-disposed

mixture within the spoil. A small num-

ber of coal mines in Eastern Australia

has employed either on-off temporary

surface tailings storage cells in which

the tailings are desiccated and har-

vested periodically and dumped with

coarse-grained wastes, or pressure

plate filtration. The tailings manage-

ment options considered are:

1. A series of surface TSFs.

2. An in-pit TSF.

3. On-off temporary surface tailings

storage cells.

4. Pressure filtration and “dry” dis-

posal of the tailings filter cake with

coarse-grained wastes.

5. A surface TSF until a completed

pit becomes available for tailings

disposal.

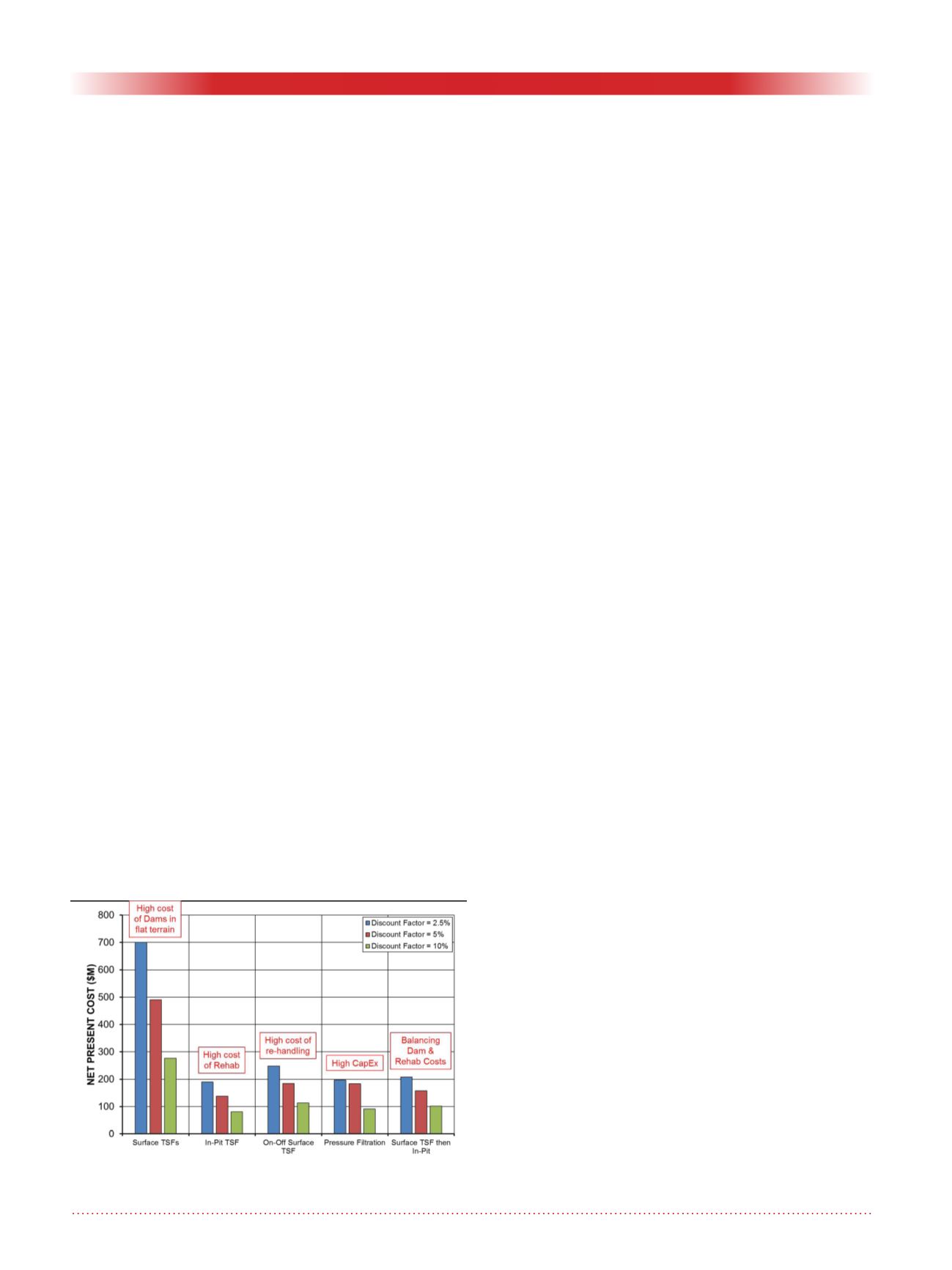

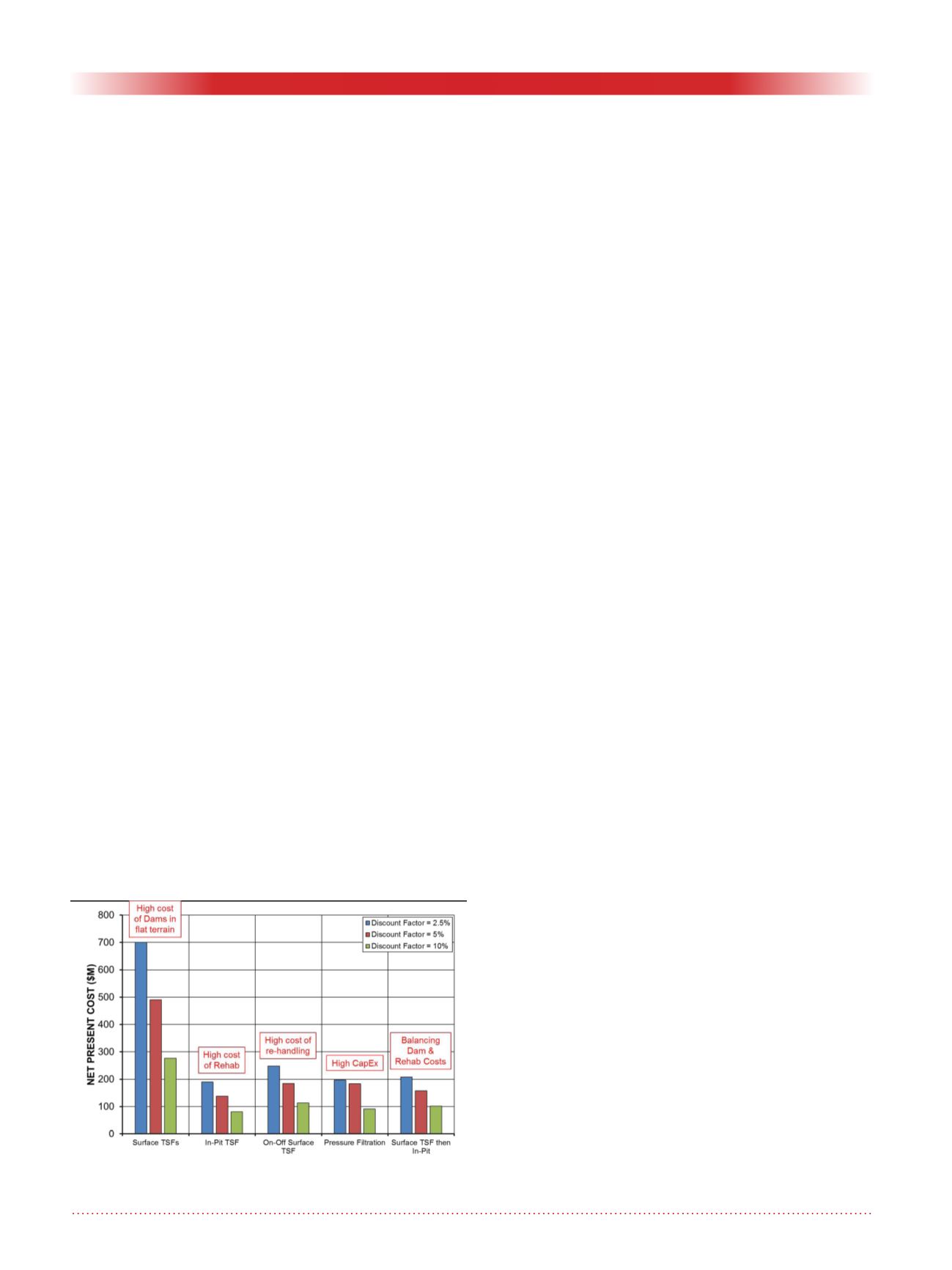

NPV analysis of capital and

operating costs

Figure 1 illustrates NPV capital

and operating cost comparisons for

Discount Factors of 2.5% (close to the

Consumer Price Index), 5% and 10%,

applied to the tailings management

options considered. These compari-

sons do not include closure and reha-

bilitation costs.

The high costs of the series of surface

TSFs would surprise many, but arise

from the flat terrain of the Eastern

Australian coalfields providing limited

“free” valley storage for tailings and

requiring an ever-increasing length of

dam around the perimeter of a surface

TSF. This limits the height of each

TSF due to the excessive cost of dam

raising and the ever-increasing length

of perimeter dam required, forcing a

new surface TSF to be constructed.

An in-pit TSF is the least expensive

option, but this assumes that a pit

is available from the start, which

is unlikely. The other three options

attract similar capital and operating

costs. The costs of on-off temporary

tailings cells are dominated by high

re-handling costs, although drying by

the sun and wind is relatively robust,

with high rainfall affecting less than

30 days per year on average in the

Eastern Australian climate. The costs

of pressure filtration

are dominated

by the high

up-front cost

of the equip-

ment, which is

the main reason

why this option

is often removed

from consider-

ation early in

the selection

process. Pressure

filtration is also

sensitive to the

inevitably vari-

able input stream, resulting in opera-

tional difficulties, particularly for clay

mineral-rich coal tailings. The initial

use of a surface TSF until a completed

pit becomes available for tailings

disposal appears to be marginally the

best option.

Including closure and rehabilitation

costs

Figures 2 and 3 show, respectively,

NPV comparisons at Discount Fac-

tors of 10% and 2.5%, for a series of

surface TSFs, including operational

and rehabilitation costs. Three surface

TSFs are operated during the 20-year

life of the coal mine, the first to year

7, the second from year 7 to year 15,

and the last from year 15 to year 20.

Rehabilitation of the TSFs is carried

out progressively, the first in year

7, the second in year 15 and the last

in year 20. A 10% Discount Factor

obscures the cost of TSF rehabilita-

tion, which is by far the major cost

impost in undiscounted terms, while

a more realistic 2.5% Discount Factor

better reflects the real and substantial

cost of rehabilitation. Leaving the

rehabilitation of all three TSFs to the

end of the mine life would reduce the

heavily discounted cost of rehabilita-

tion further, while likely to raise the

actual cost.

Rehabilitation security deposit

New South Wales and Queensland

Regulators require coal mine opera-

tors to assess and submit a Security

Deposit against future mine site reha-

bilitation. Both the New South Wales

Rehabilitation Cost Estimation Tool

,

and the Queensland Mining Financial

Assurance Calculator

provide the same

indicative costs for reshaping, cap-

ping/sealing tailings:

• AUD170 000/ha for tailings likely

to present considerable difficulties

due to reactive and/or soft tailings.

Figure 1. NPV comparisons of alternative tailings storage

scenarios.