36

Geotechnical News • March 2019

WASTE GEOTECHNICS

molecules that went down at time 1

and the amount of molecules that went

up at time 2, then we can calculate a

net flux over a period of time (Burba,

2013).

Typical sampling rates for ECV

applications are in the order of 10 Hz

or higher, producing large amounts

of data. This data is processed via

applying a series of conversions and

corrections that are computer intensive

that at the end lead to the evaporation

rates.

One of the important characteristics of

the method is that the ECV instrumen-

tation has to be installed downwind

of the area of interest. The size of the

footprint, that is, from how far upwind

the ECV will be capturing data, will

depend on the height of the instrumen-

tation above the surface of interest

and its roughness. Another important

feature is that winds coming from any

direction different from the area of

interest can be filtered out using the

sonic anemometer wind direction data,

thus avoiding the contamination of

data from other areas.

A bit of history, applications and

advantages of the use of ECV

The ECV method has been around in

the scientific community for a couple

of decades. The theoretical develop-

ment of the method was done in 1948,

but it was not until 1962 that the

3D sonic anemometer and the water

vapor gas analyzer were available.

Only in 1988 a real-time data pro-

cessing software was developed, and

by the year 2000 a methodology and

the organization of an international

network (FLUXNET) was established

(Aubinet, 2012).

The ECV method has been widely

used to measure gaseous exchange

between the forests and the atmo-

sphere at different latitudes

worldwide. The Centre for Earth

Observation Sciences (CEOS) at

the University of Alberta, led by Dr.

Arturo Sánchez-Azofeifa, currently

operates two ECV stations that are

monitoring boreal

and tropical dry

forests.

The ECV method

is suitable for

measuring water

vapor fluxes in

large and flat

extensions of

areas, either veg-

etated or not. The

main restriction

is that the instru-

ments must be

located downwind

of the area of

interest. The main

advantages of the

method applied

in mining settings

are:

• It causes no disturbances on the

surface and can be used in tailings

ponds since it can be installed at

the edge of the TSF, downwind of

the area to be measured.

• Obtains spatially averaged fluxes

for areas with footprint fetches

ranging from 200 m to 800 m.

• It can provide flux estimations for

periods of hours to years, depend-

ing on how long the instrument is

deployed on site.

• It is the only method for actual

evaporation measurement that

enables quality assurance of the

obtained results through math-

ematical calculations (cospectra

analysis), leading to reliable

evaporation rates.

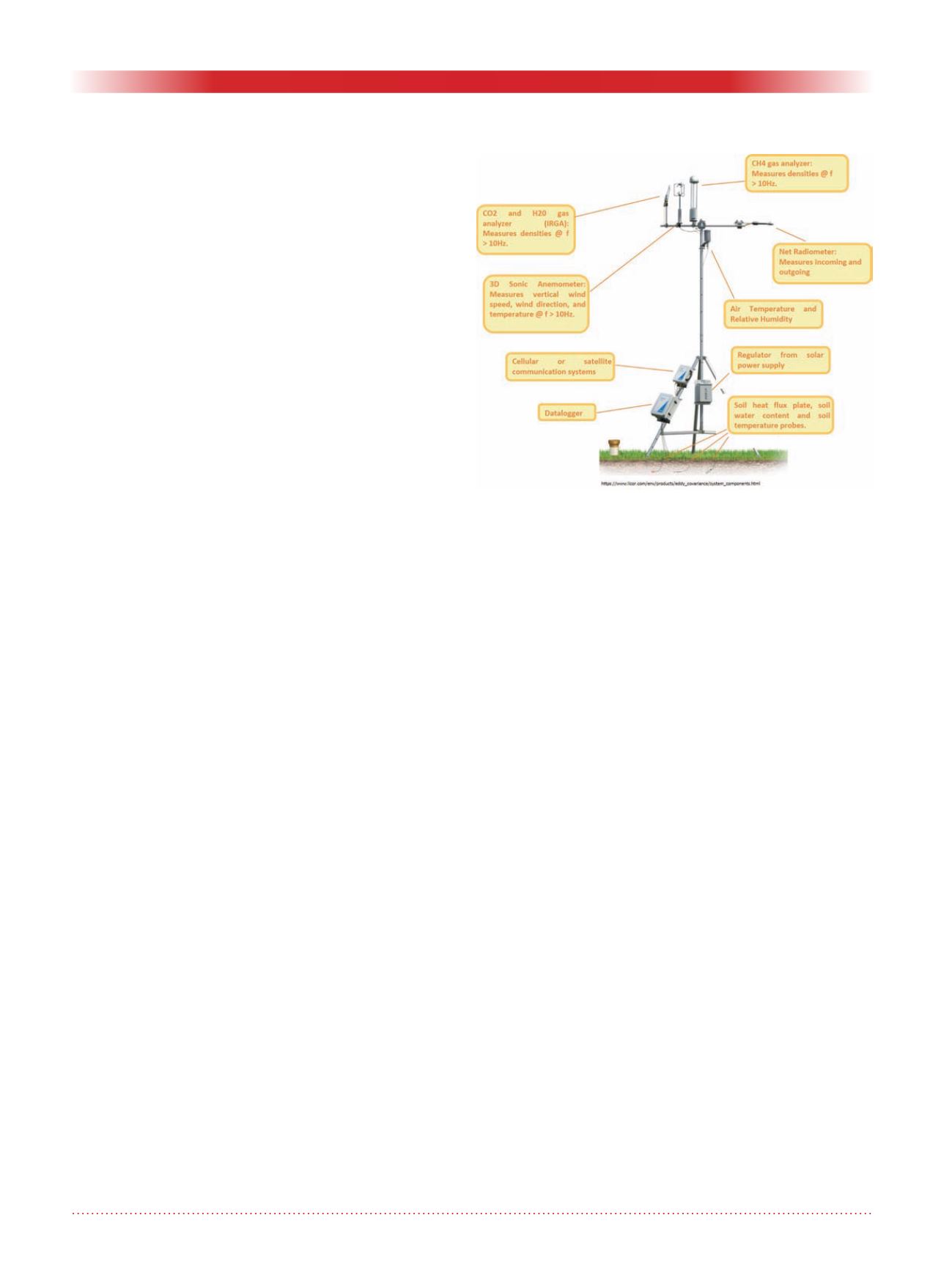

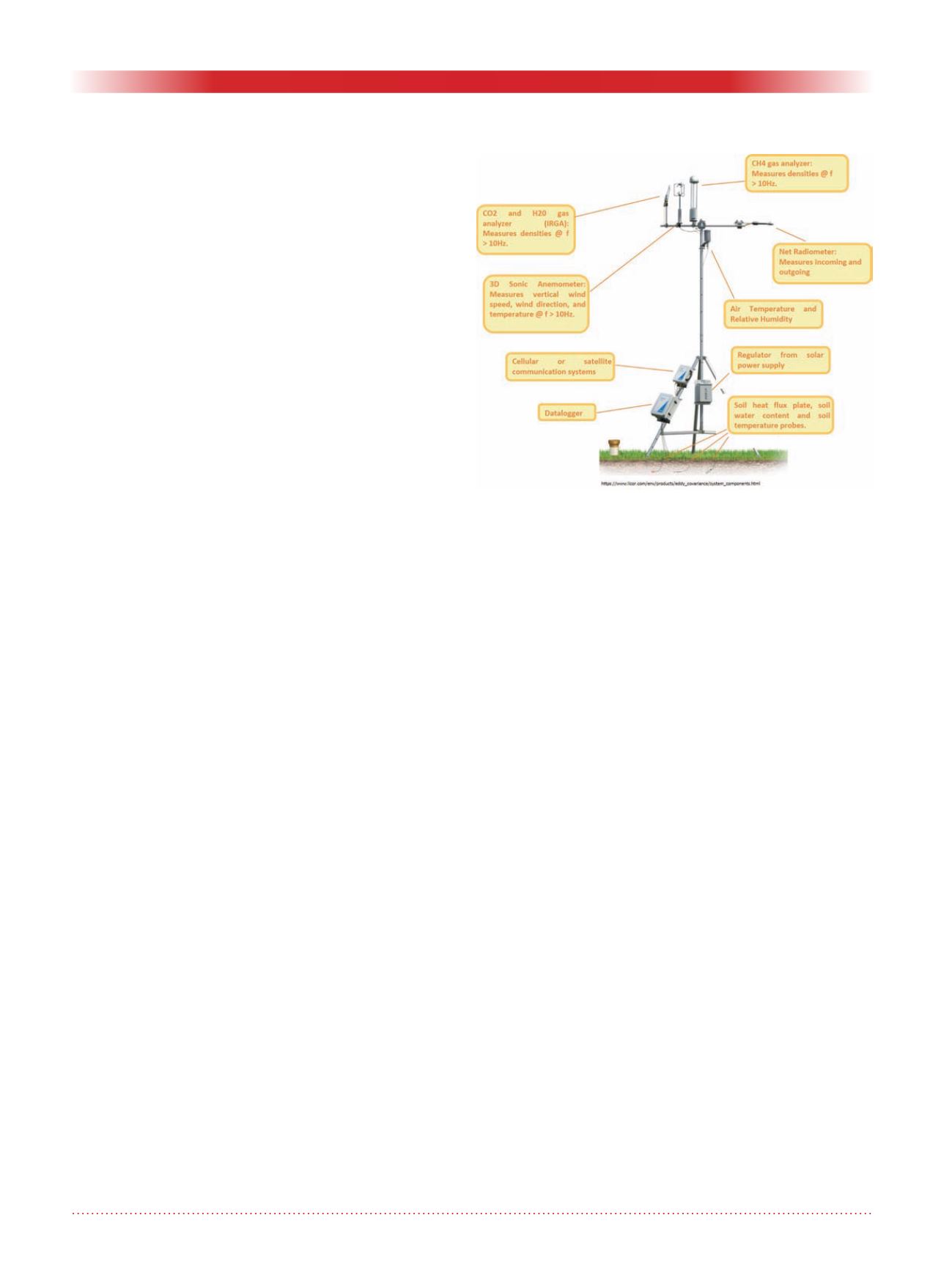

ECV equipment

The main components of the ECV

are the gas analyzer, which measures

water vapor and carbon dioxide con-

centrations, and the sonic anemometer

that measures wind speed and direc-

tion. Both instruments sample at fre-

quencies of at least 10 Hz in order to

capture small eddies (Foken, 2012). In

addition, the system has a datalogger

and a processor that is able to pre-pro-

cess and store the data collected from

the ECV. Also, meteorological data is

collected on site, and biosensors are

installed in the ground. Figure 1 shows

a typical ECV set up:

In addition to water vapor and carbon

dioxide measurements, a methane gas

analyzer can be added. The system,

if provided with a cellular or satellite

communication package, can be moni-

tored remotely, allowing for real-time

data collection and processing.

Finally, depending on the type of sur-

face where the ECV will be installed

(e.g. tailings or waste rock dump),

an additional energy balance closure

check could be performed. This can

be conducted using the measurements

of net radiation and ground heat flux,

together with the latent and sensible

heat fluxes measured by the ECV. For

this reason, a net radiometer and a soil

heat flux plate are usually considered

for typical site deployment.

Ongoing research

The Department of Civil and Environ-

mental Engineering at the University

of Alberta is currently conducting

research supervised by Professor G.

Ward Wilson in collaboration with

Dr. Sánchez-Azofeifa and led by PhD

student Sebastián Fernández to adapt

and apply the ECV method on mine

Figure 1: Typical ECV set up. Source:

.

com/env/products/eddy_covariance/system_compo-

nents.html.