Geotechnical News December 2010

31

Geotechnical Instrumentation News

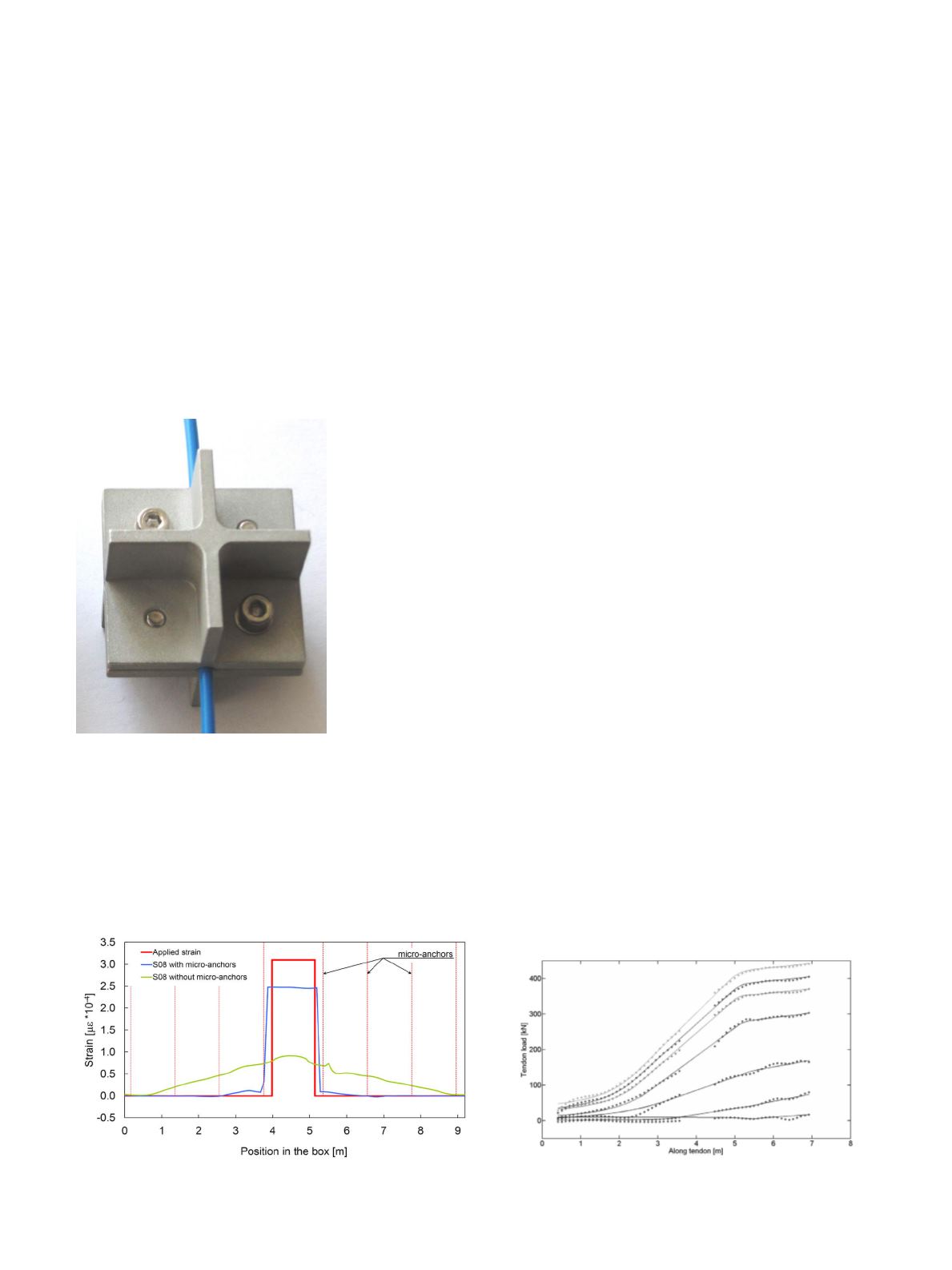

system has been developed (Figure 2).

The principle of this second system

is that a FO cable fixed to “micro-

anchors” buried in soil experiences the

same movement than the soil around

it. The “micro-anchor” (Figure 3)

consists of three perpendicular planes

in order to provide bearing resistance

in all directions and to act as a three

dimensional “dead” anchor. The anchor

size (side length of 40mm, 60mm

or 80mm, respectively) is chosen as

a function of the anchor depth and

the stiffness of the chosen FO cable

(preferably S08 and S09, Table 2).

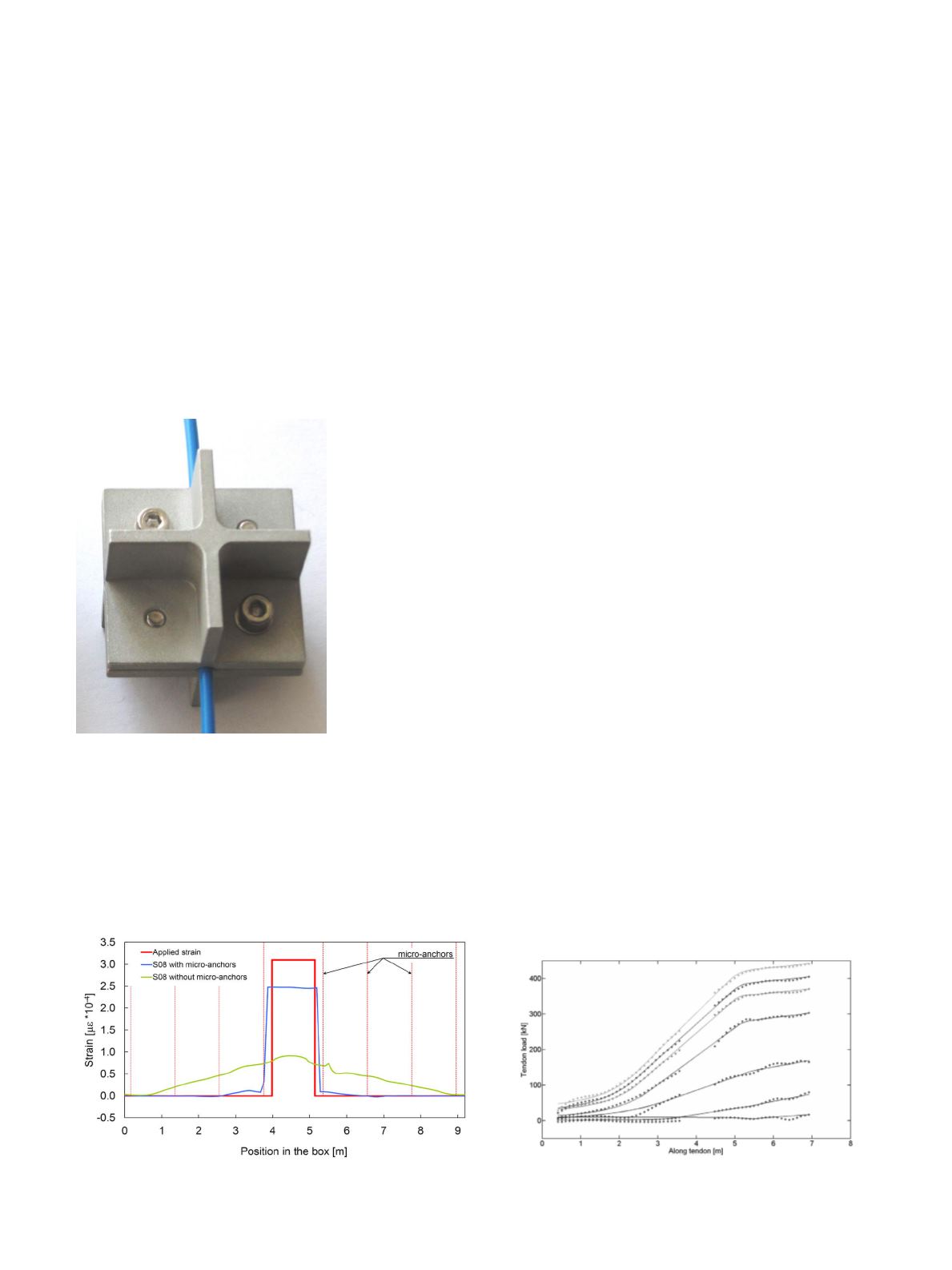

Large scale laboratory testing of the

system in a 9m long shear box proved

the system to be very efficient. Com-

pared with data obtained by FO cables

buried without anchors and FO cables

embedded into geotextiles, this system

is significantly more sensitive. Figure

4 shows data from such a test of a FO

cable without anchors and a FO cable

with anchors. Additionally to the labo-

ratory testing, an 80m long system has

been successfully installed in a field

project in St. Moritz. The temporal

change in the measured strain incre-

ments correlates well with the indepen-

dent geodetical and inclinometer mea-

surements in this location.

Reactivation of Old

Inclinometer Casings

The third monitoring system takes

advantage of old, out-of-service,

inclinometer casings. In order to

continue using such casings, a FO

cable (P07 or S08, Table 2) is placed

inside and the casing is filled with

cement-bentonite grout. The current

sliding surface can then be identified

and displacements on this surface

back-calculated. Installation of such a

system on site in 2008 allowed for the

sliding surface to be detected within

three months.

Applications in Ground Anchors

Motivation

The determination and monitoring

of the stress distribution along the

grouted section of a loaded ground

anchor tendon is essential for the

understanding of its bearing behavior.

Strain along anchor tendons is normally

measured at distinctive points by

various sensors, such as conventional

strain gauges and more recently, fiber

Bragg gratings. Other approaches are

based on elongation measurements

in a very limited amount of tendon

sections, such as the regularly-used

commercially available monitoring

anchors that offer strain readings in up

to four sections.

A novel monitoring ground anchor

using embedded FO cables allows for

continuous strain assessment along the

anchor tendon, and thus provide a pow-

erful tool for calculating the load distri-

bution in the anchor tendon, which is of

interest to the geotechnical community,

as other reliable methods are rare.

Design and Installation

The monitoring anchor is built of a

tendon consisting of a hollow steel

bar with a threaded outer surface of

35mm diameter. As the integration of

FO cables is one of the key factors,

two different integration methods were

tested: integration in grooves machined

on the outside of the tendon at 180

degrees to each other and internally

in the hollow of the tendon. In the

groove (1mm wide, 2mm deep), the

FO cables (BSM, TSM & P07) are

directly glued to the tendon. In internal

integration, the FO cables (P07, S08

& M07) are placed inside the hollow

center of the tendon later filled with a

low viscosity injection resin. In 2009,

such an 8m long monitoring anchor has

been installed in a drillhole with a fixed

anchor length of 5.75m (grouted). The

anchor was integrated into a sheet pile

wall supporting an excavation pit.

Monitoring

During anchor pullout testing, the

anchorwasloadedinstagesupto470kN,

almost reaching its ultimate bearing

capacity. BOTDA measurements were

taken at each loading stage recording

Figure 4. Strain measurements in a shear box obtained by a

FO cable only and the “micro-anchor” - FO cable system.

Figure 5. Monitoring ground anchor: load distribution from

FO measurements for selected load steps.

Figure 3. The “micro-anchor”.