20

Geotechnical News •September 2015

GEOTECHNICAL INSTRUMENTATION NEWS

were objections to removal of the

system. These generally came from

occupants of buildings adjacent to the

cut and cover stations. After 13 years

of continuous monitoring they were

accustomed to the security provided

by the system. This was especially so

for the inhabitants adjacent to one sta-

tion where a number of construction

incidents had occurred that resulted

in very severe localised settlements.

In the initial stages of close-out

monitoring removal of the systems

was discussed with these groups. By

addressing their concerns the stake-

holders were then convinced the moni-

toring system was no longer required.

General - removal of a

monitoring system

Removal was the final element of the

contract awarded to Soldata-Grontmij

JV (SG) (by Dienst Metro (DM), who

procured the Metro line for the Munic-

ipality of Amsterdam (MoA) who had

installed, maintained and operated the

monitoring system. The main compo-

nents to be removed were:

• 74 RTS including computers, sup-

port brackets, wiring and power

boxes.

• Over 6000 prisms.

• Communication infrastructure,

including Wi-Fi, 3G modems,

brackets, wiring and aerials.

• Combined in-place inclinometer/

extensometers, piezometers and

associated infrastructure, such as

access chambers; ducts, cabling,

data loggers & instruments.

• Power supplies.

A number of these elements were to be

removed from the exterior of historic

buildings such as Amsterdam Central

Station, Beurs van Berlage (the old

stock exchange) and De Munt Toren.

To ensure that there were no building

damage issues or planning problems,

the removal had to be undertaken in

an agreed fashion. Guidance in the

contract was that after removal the

contractor was responsible for making

good the underlying materials.

Given this requirement DM and SG

agreed on a removal strategy dictated

by:

• Duration: A shorter time span for

removal was more cost-effective

for SG. This required DM to

streamline permissions from

various departments within MoA,

building occupants and other

stakeholders and communicate

those plans in a timely fashion to

occupants and building owners.

• Quality: Fast tracking was permit-

ted providing only that quality was

not compromised. SG trialled a

number of removal/making good

methods to various materials

before work commenced. The suc-

cessful methods were implemented

and a rigorously documented

system put in place. Each element

to be removed was photographed

both before and after removal.

Removal of monitoring

equipment

Robotic total stations and monitoring

prisms

The main component was the support

bracket removal. During removal a

number of issues were encountered.

Accessibility: Not all prisms and

instruments were located on readily

accessible places. This meant that

sometimes the trade-off was made to

not maintain or remove certain prisms.

Making good: After removal holes

(diameter 8 mm) remained. The

contractor was obliged to making

this good. DM specified a number of

requirements for this filling:-

• Aesthetically pleasing, e.g. flush

with surface and matching colours

of surrounding material.

• Ability to fix to a number of sub-

strata.

• Not sensitive to differences in

temperature (i.e. low alpha coef-

ficient).

• Life expectancy similar to the sur-

rounding materials.

Generally the material to which RTS

brackets and prisms were attached

consisted of brick, (from relatively

new to very old), mortar joints and

natural stone. Two main filler types

were considered:

• 2-part epoxy based mortars

• Cement based mortars

After careful consideration and trials

of both materials, epoxy mortar was

the preferred option. Both could fulfil

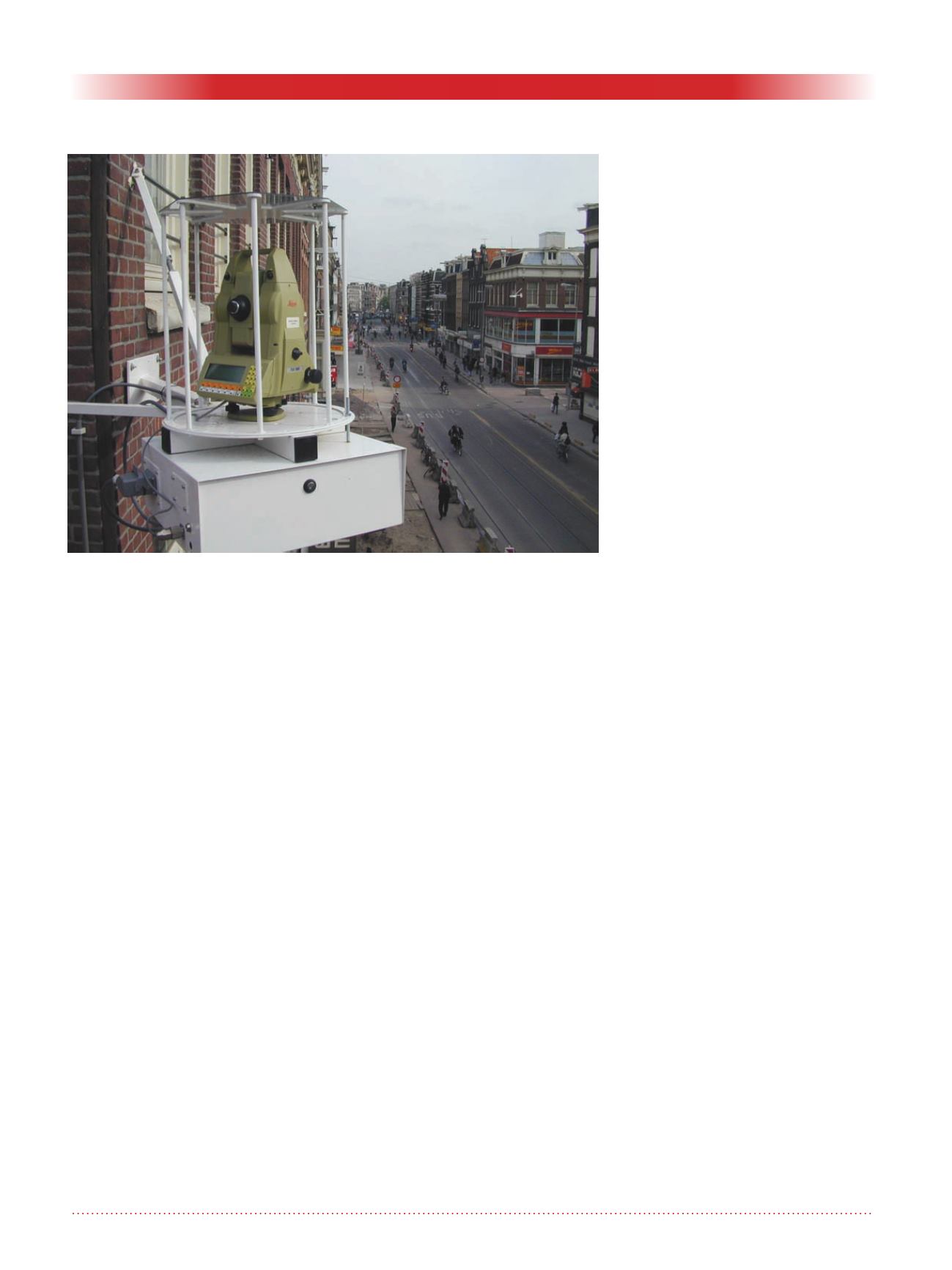

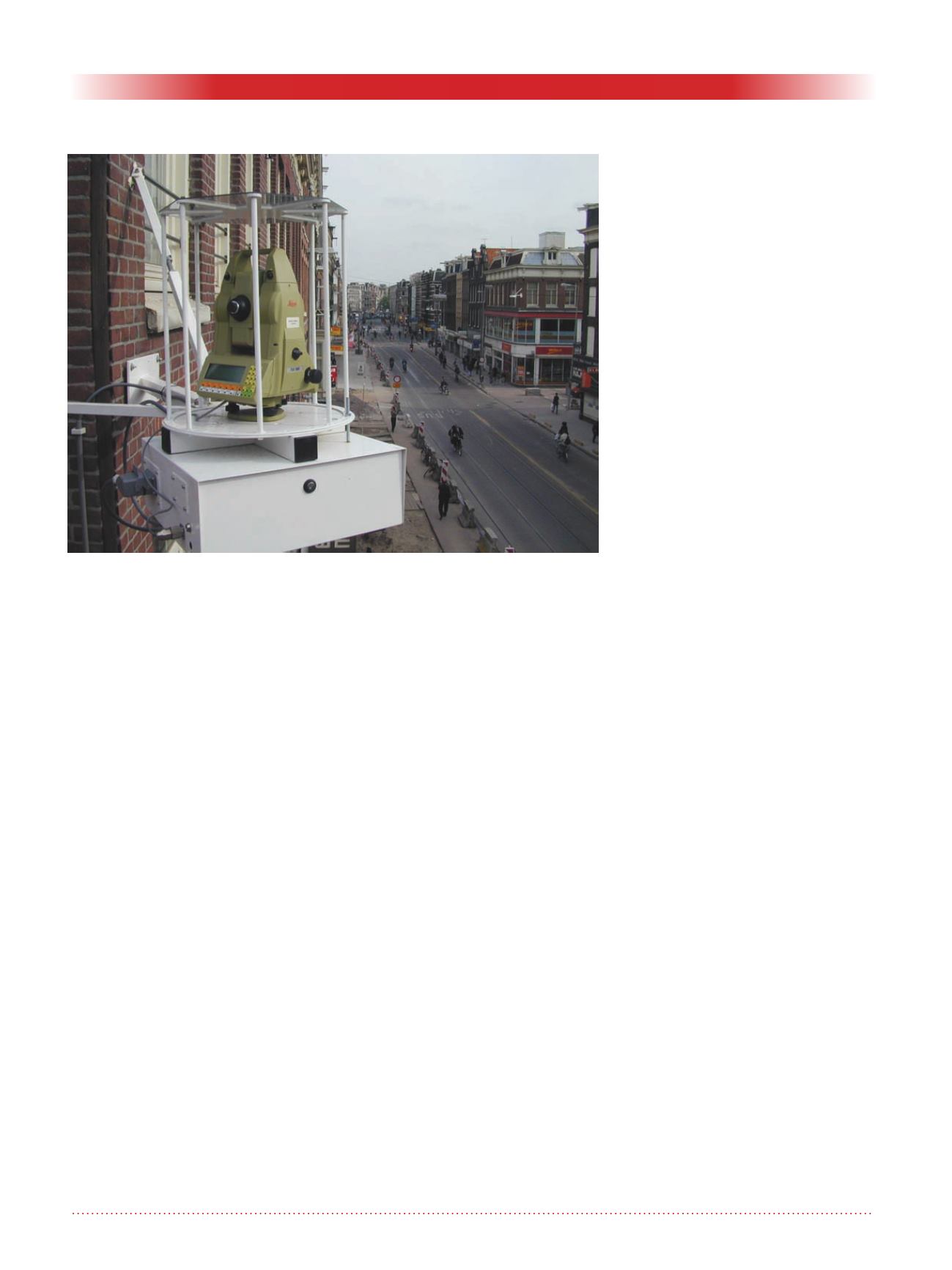

Figure 1. Typical RTS installation – (Photograph courtesy of SolData; all

rights reserved).