46

Geotechnical News • June 2016

GROUNDWATER

two other reasons were retained in the

1980s field investigations following

the poor performance of the liners.

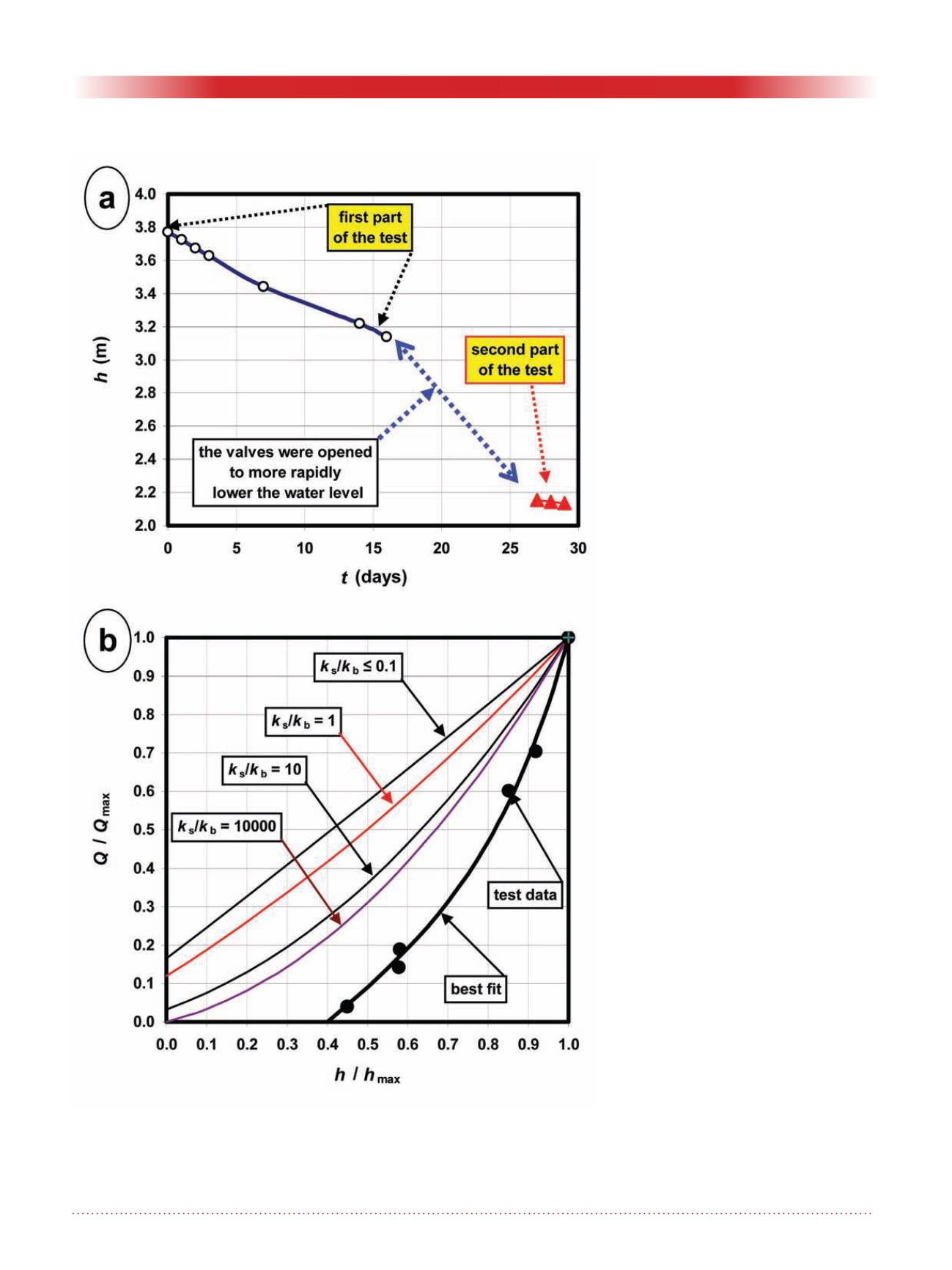

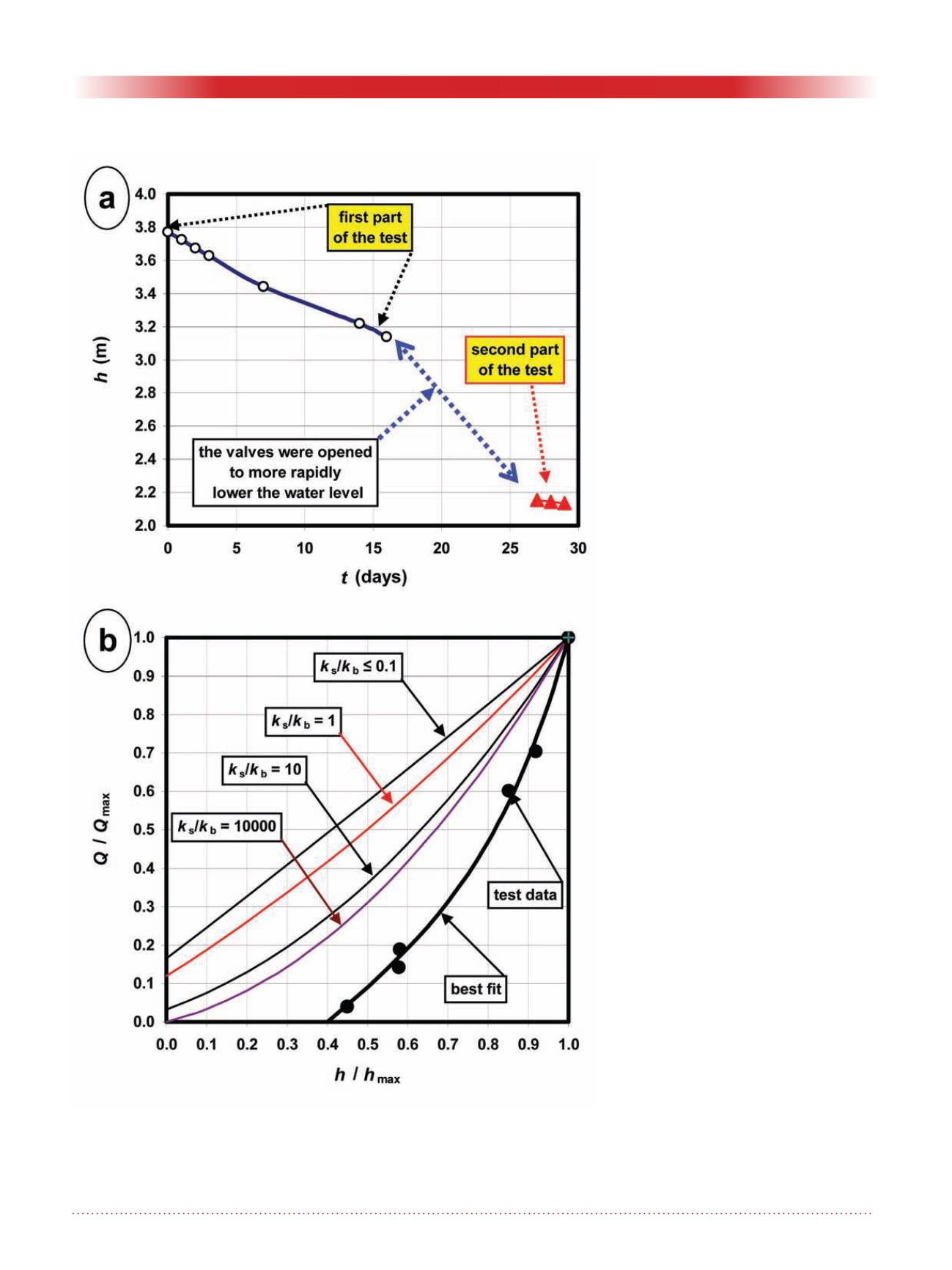

The results of the two full-scale leak-

age tests showed that the leakage was

reduced when the water levels reached

mid-slope. Because the water thick-

ness above the liner had been halved,

the leakage rate should have been

roughly halved. However, this was

not the case. Leakage rates were only

1-2 mm/d (these small values were

inaccurate) and thus, much less than

half the leakage rate at full water level.

These findings led the author, acting

as an expert in the 1980s, to suspect

that mid-slope pipes were improperly

sealed or the upper parts of the liners

were too permeable.

A possible indication of damage in

the upper parts of the liners was found

in the July report of the construction

inspector who reported cracking in

the upper slopes. The engineer then

requested a verification that the cracks

would not be more than 3 to 5 cm

deep, otherwise the contractor would

have to spray water to increase the

clay water content, re-mix the 15-cm

clay lift, and re-compact it. This may

have been done, but there was no writ-

ten evidence of this in subsequent field

reports. In addition, the two lagoons

did not receive rain water or water

spraying during weeks between the

end of their construction and the full-

scale leakage tests. This situation was

physically detrimental to the liners.

A few weeks after the full-scale tests,

all participants in the project agreed

to empty the two lagoons. This was

needed so that the reasons for the poor

performance could be investigated.

Field verifications of the liners

and pipes

After the full-scale leakage tests, the

lagoons were emptied for inspection.

Shelby clay samples were taken in the

upper slopes. The liner thickness in

the upper slopes, supposed to be 75

cm, was only 45 cm on average for

liner No. 1, and 40 cm for liner No. 2.

The measured values ranged from 29

Figure 2 Full-scale leakage test, lagoon 1: (a) water level versus time; (b)

non–dimensional graph of relative flow rate Q/Qmax versus relative water

thickness h/hmax for the same lagoon geometry.