Geotechnical News • June 2016

47

GROUNDWATER

to 55 cm for liner No.1, and from 23

to 59 cm for liner No. 2. The samples

had a few subvertical cracks crossing

the full thickness. In addition, 30% of

clay samples contained thin, less than

1-mm thick, layers of sand within the

clay liner, probably resulting from

poor handling of materials during con-

struction. Therefore, the first suspected

reason for poor performance, some

clay damage or poor quality work

in the upper parts of the slopes, was

verified.

The second suspected reason, a poor

seal along the pipes, was also inves-

tigated. During a site visit, when the

water levels had been lowered, the

author could see open spaces just

below the pipes with widths between

5 and 8 cm. The spaces were sounded

using a rod: they were opened along

the full liner thickness. Smaller (1-2

cm) open spaces were also found

above and around the pipes, after the

crushed stone had been removed to

expose the contact between clay and

pipe. A representative pipe is shown

in Fig. 4. Thus, the second suspected

reason was also verified.

Reason for the poor seal along

the pipes

Initially, the clay had been tightly

compacted against the pipes, which

had been installed during dike con-

struction and before liner construction.

Subsequently, a gravel protection was

laid everywhere over the liner, with

a special shape and increased thick-

ness around the ends of the pipes, as a

protection against erosion. The open

spaces that were found along the pipes

may have been caused first by thermal

dilation and contraction, and then

enlarged by water erosion.

The pipes were laid in June. The field

inspector reported that the contact

between clay and pipe was good.

During its installation, a pipe was at a

temperature close to that of the newly

placed clay (≈ 10°C). However, in

the next few weeks, its temperature

increased significantly (from about 10

up to 35

°C),

because the empty pipe

was in contact with the hot air inside

it. All pipes were made of plastic.

Their thermal dilation coefficient is

about 12 times higher than that of

cement concrete or steel (Chapuis

1990a). Therefore, the plastic pipes

dilated, their wall pushed away the

clay, thus tightening the seal at the

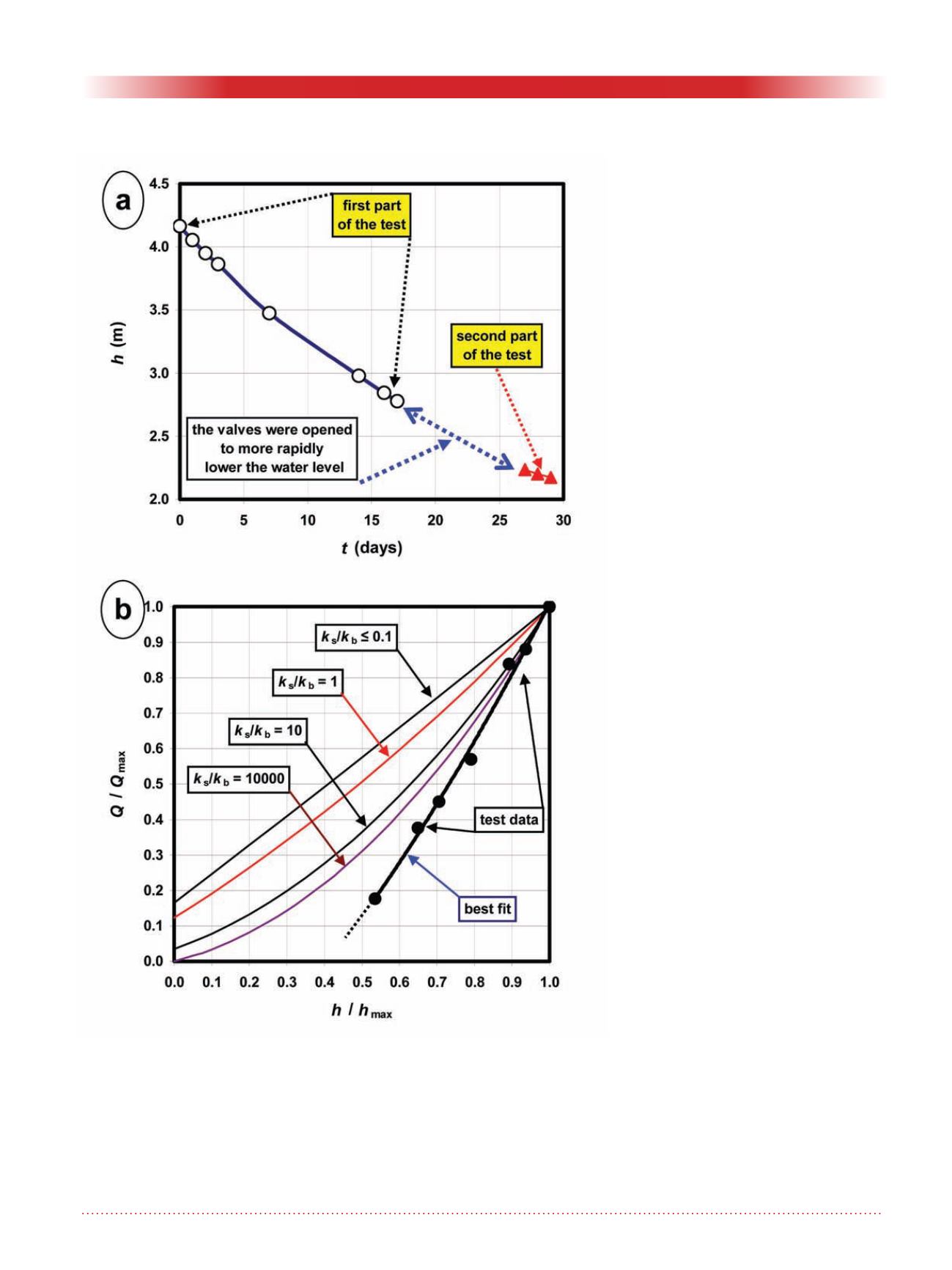

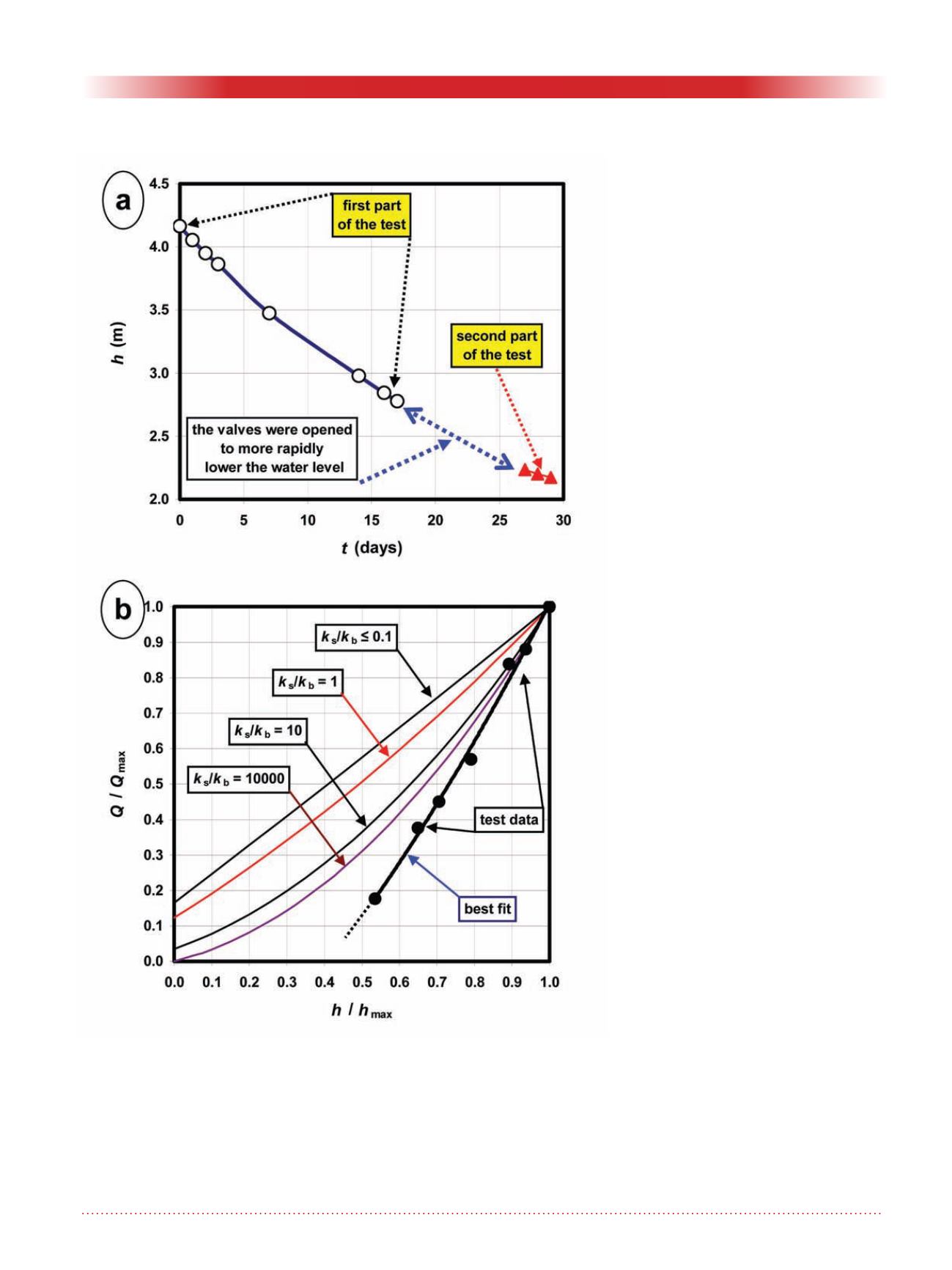

Figure 3. Full-scale leakage test, lagoon 2: (a) water level versus time; (b)

non-dimensional graph of relative flow rate Q/Qmax versus relative water

thickness h/hmax for the same lagoon geometry.