28

Geotechnical News • June 2017

THE GROUT LINE

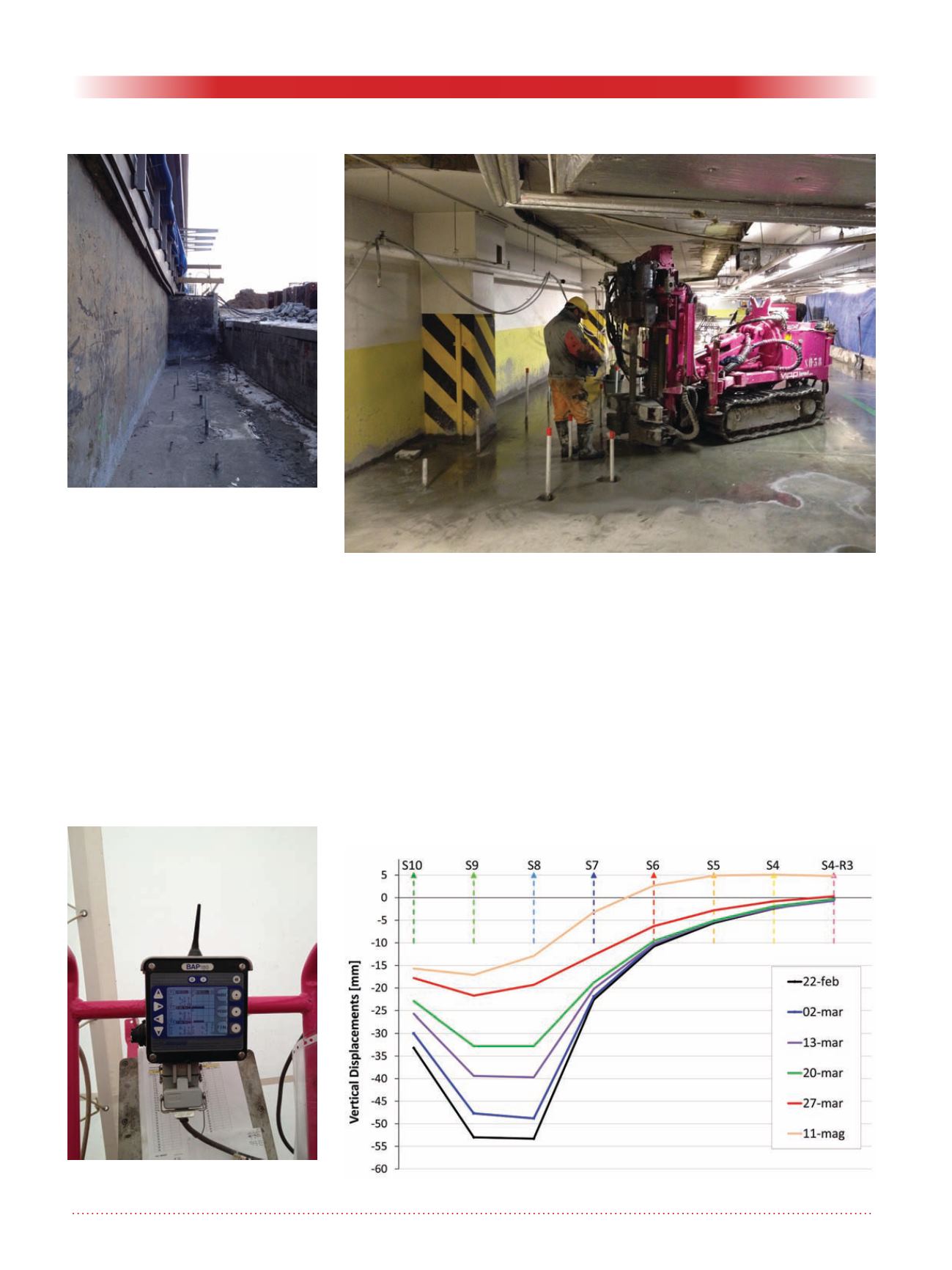

underground floor, in narrow spaces

(the average height was 2,30 m) (Fig.

7).

The structures were controlled by an

automatic topographic monitoring

system (Fig.8); optical prisms were

placed in correspondence of each

pillar.

The grouting scheme was studied in

order to gradually uplift the structure’s

pillars; in some cases even the specific

order of the sleeves to be injected

was indicated. On the first day, a set

of holes was drilled and the sheath

injection executed. On the following

day, the first stage of the injection,

using cement grout, was carried out.

The monitored points were regularly

checked. The operative parameters

were recorded in real time and the

pressure and volumes evaluated at

the end of each working day. In some

cases, the data analysis involved

rescheduling the grouting sequence

of the following days. The continuous

and constant monitoring and recording

of the grouting parameters influenced

the timing and scheduling of the proj-

ect. On several occasions the weekly

scheduling was modified based on the

results obtained day by day. In some

cases, the weekly programming was

modified based on the data and results

obtained on a specific day.

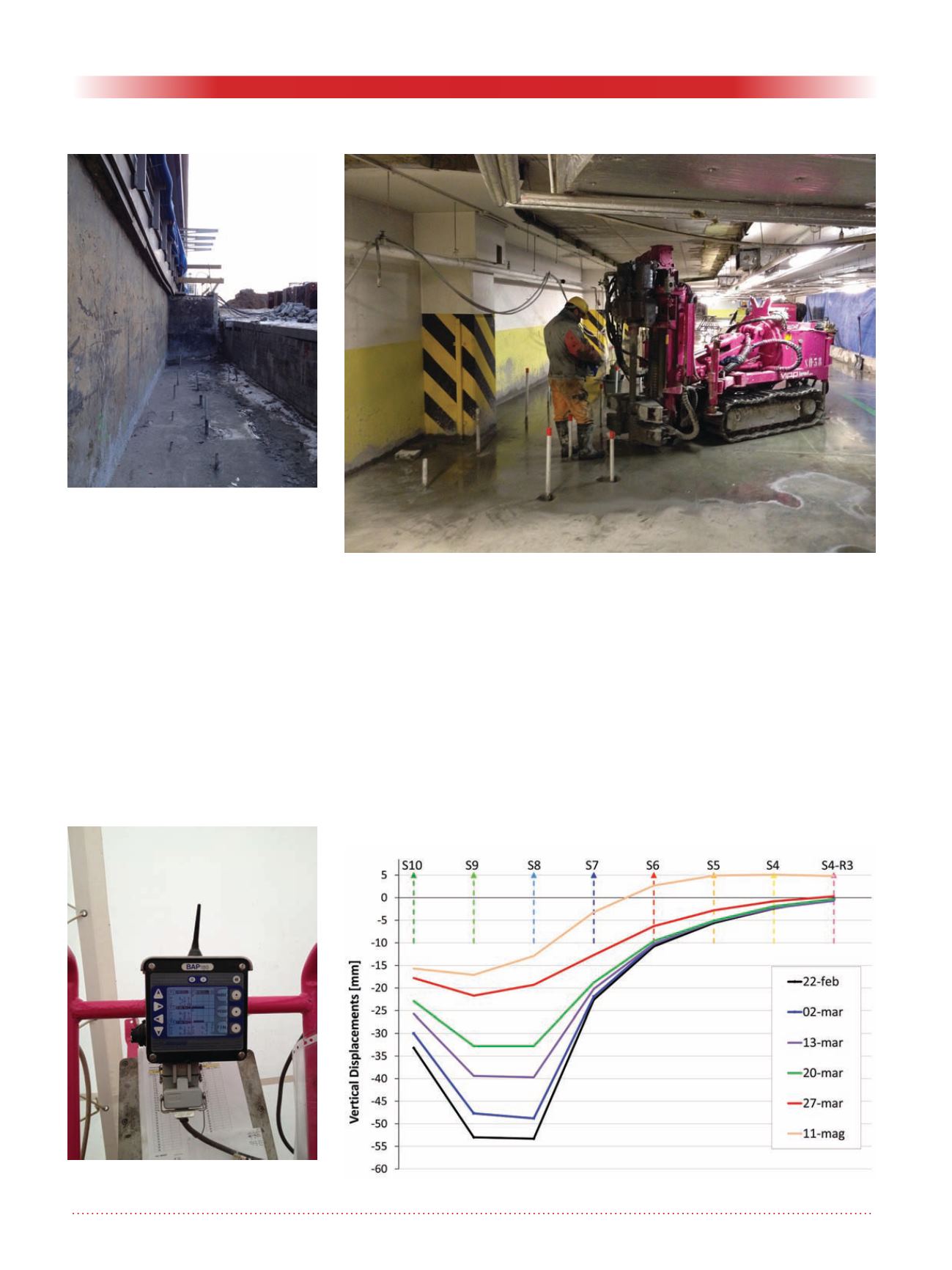

The chart of figure 9 shows the evolu-

tion of the vertical displacements

measured during the works. Firstly the

grouting with cement mix gradually

uplifted the pillars nr. 8 and 9.

Figure 6.Two rows of TAM outside

the structure, installed from a

lowered existing level.

Figure 7.Drilling works from the underground parking inside the building.

Figure 8.Topographic monitoring

system.

Figure 9. Pillars’ displacements during the grouting works.