Geotechnical News • June 2017

29

THE GROUT LINE

Few holes required an additional sec-

ond stage of cement grouting. When

the differential settlements between

the pillars were strongly reduced, the

silica grout was injected, working

gradually along the area to be treated.

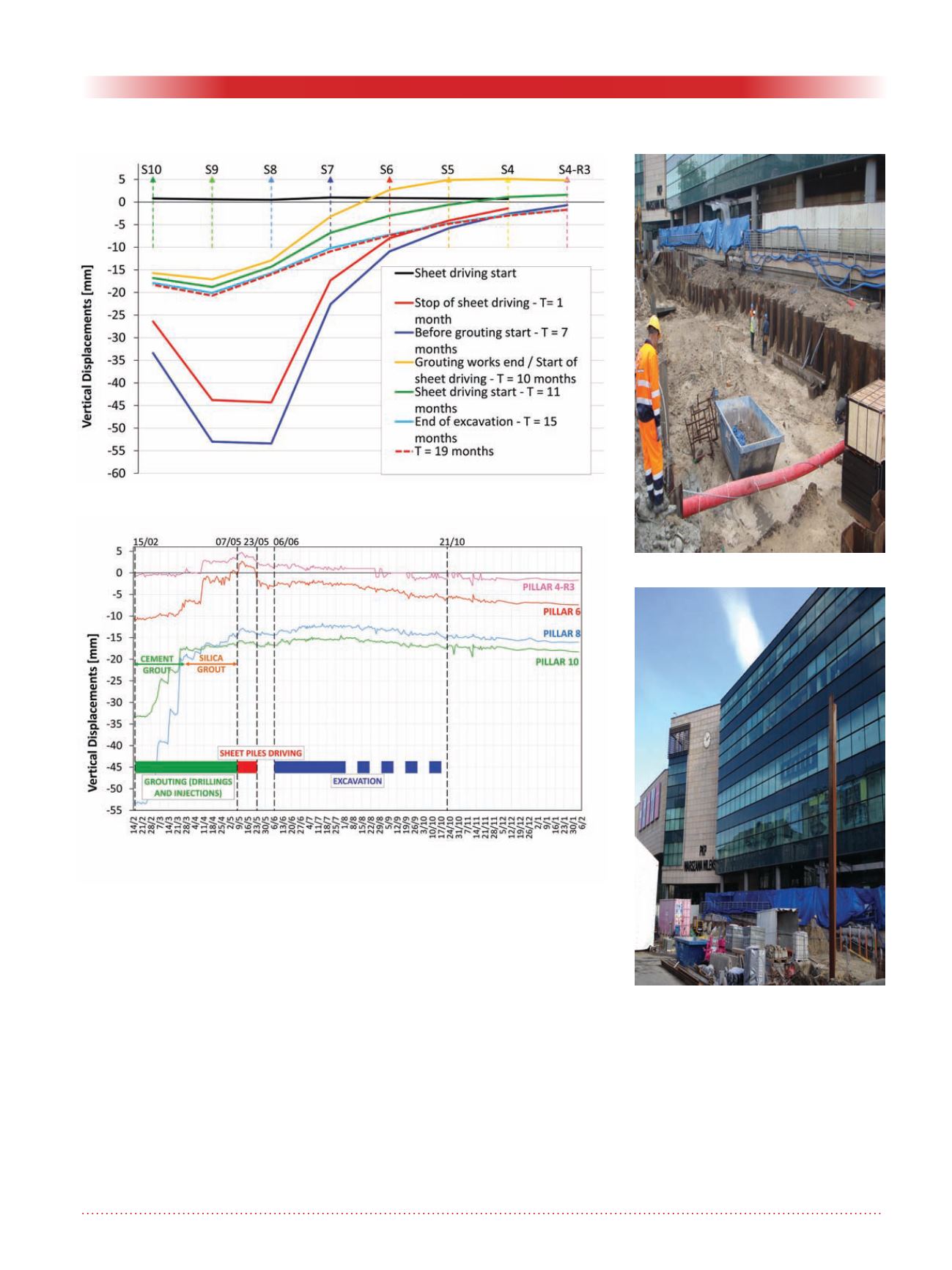

The effect of this injection stage is

shown by the yellow line in (Fig.10);

an average uplift of about 5 mm was

induced.

At the end of the treatment, the sheet

wall execution was also completed in

the area in front of pillars nr. 6 to nr. 3.

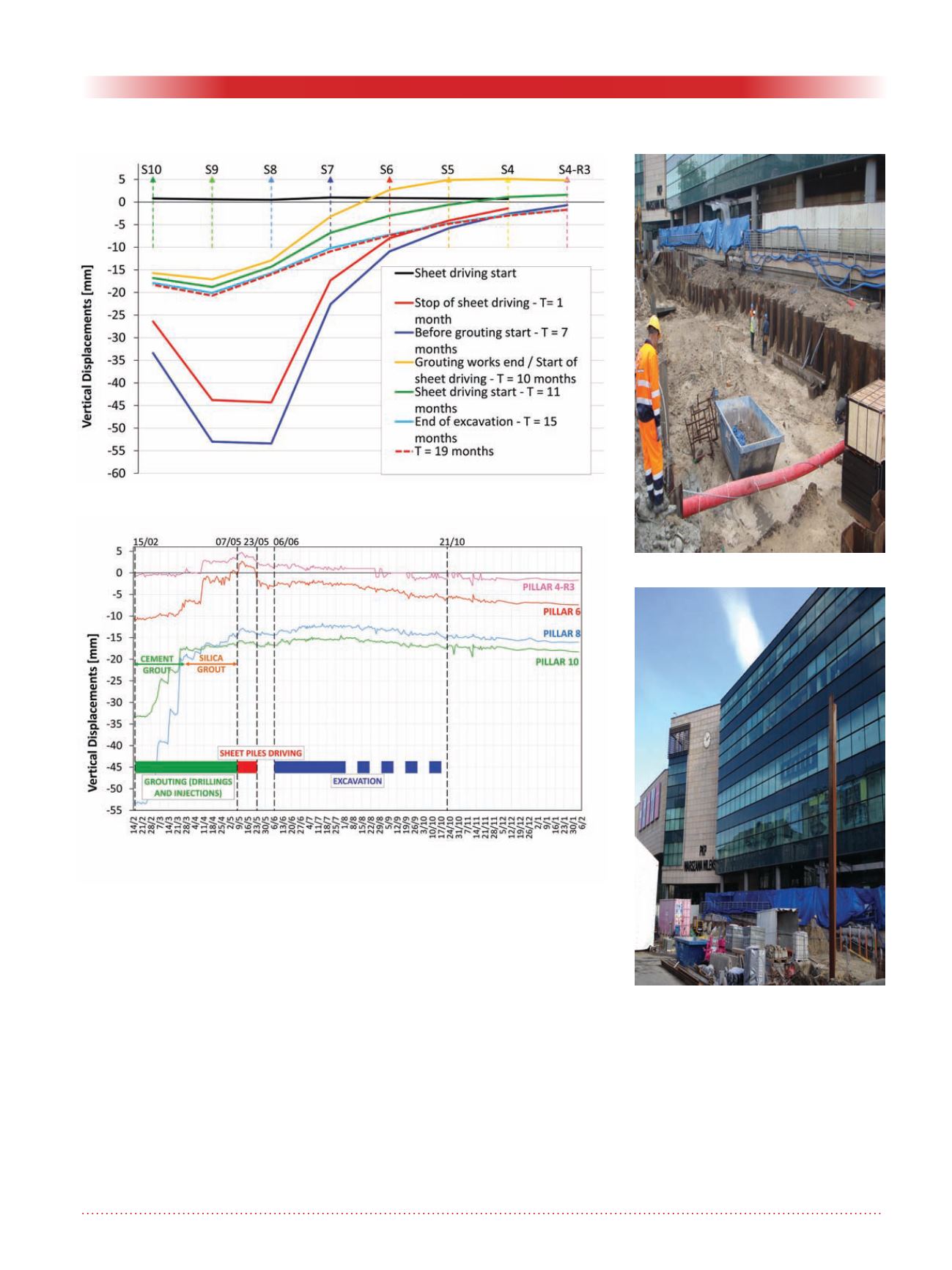

The sheet elements were now driven

into the ground without vibration. The

green curve in the following figure

11 evidences the effect of this work

on the structure. Settlements of about

5 mm were measured in the zone

besides the activities, while pillars

nr. 8 and 9, showed a very reduced

settlement (less than 1.5 mm) after the

compaction grouting works.

Finally, the excavation between the

driven sheet walls and the following

reinforced concrete lining cast was

carried out in the following 4 months.

Low residual settlements were

measured, varying from 1.5 mm to

3 mm, in the range expected by the

structural designers. The effect of the

treatment, together with the different

execution methods used, definitely

allowed for reduction of the sensitivity

Figure 11. Pillars nr. 10, 6, 8 and 4R3 displacements during all the working

phases.

Figure 10. Pillars’ displacements during the time.

Figure 12. Warsaw worksite.

Figure 13. Warsaw worksite (2).